Self-assembling type polymer solar cell negative electrode decorating material and decorating method thereof

A cathode modification and solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult control of the operation process, increase the overall time of polymer solar cells, etc., achieve low cost, simple and easy to control the preparation method, reduce The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

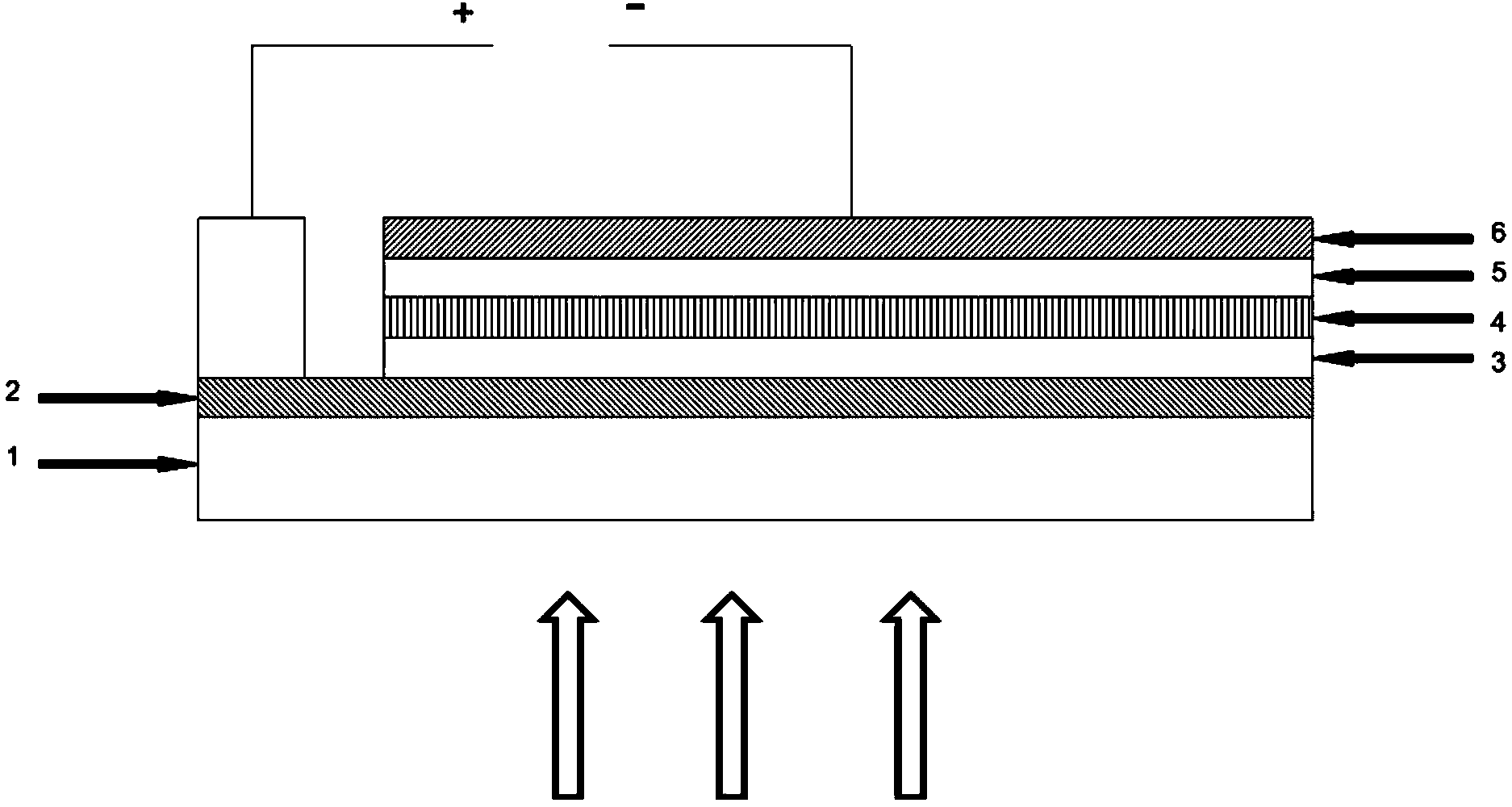

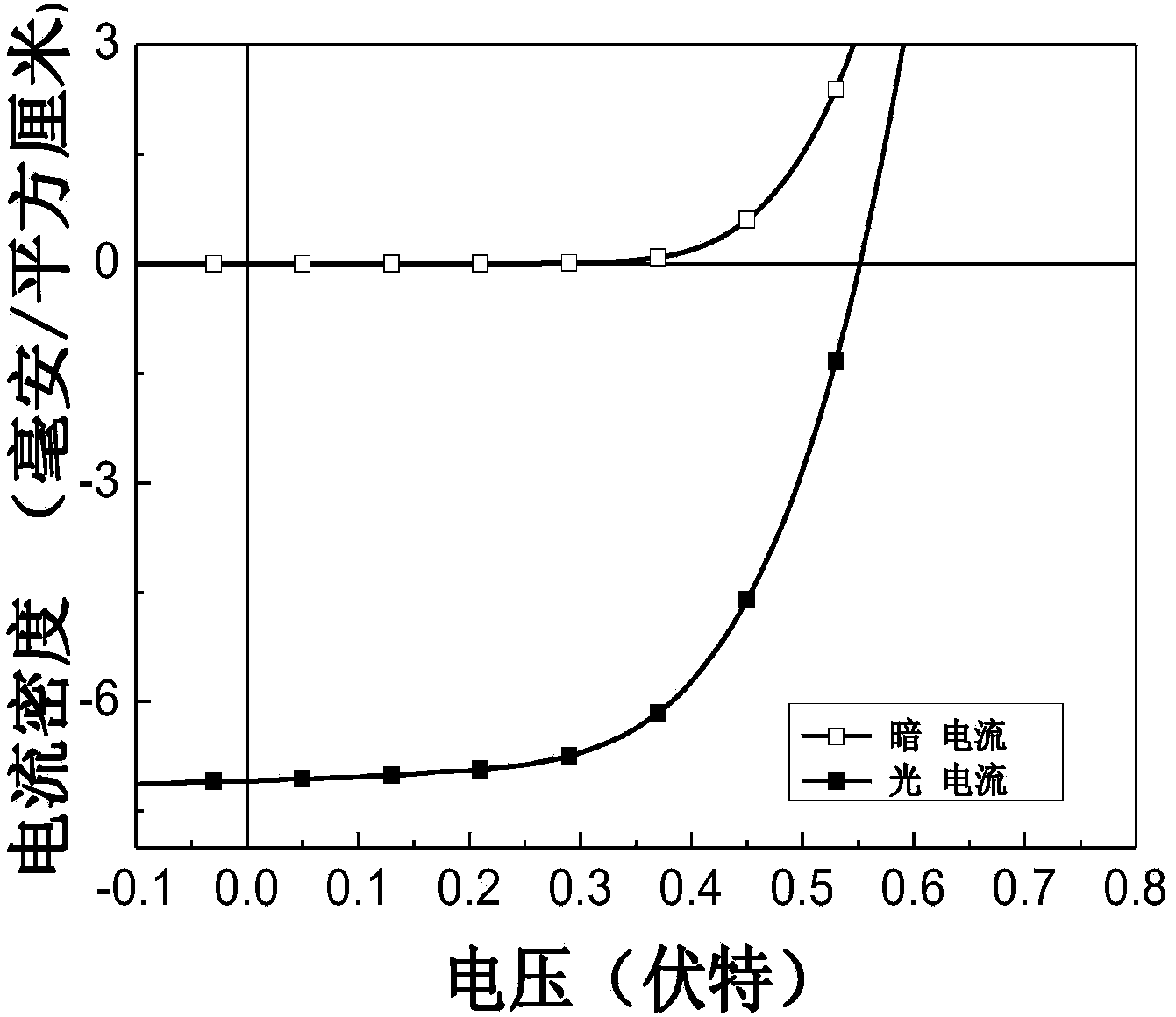

[0035] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol, dried with nitrogen, and spin-coated with PEDOT:PSS at a speed of 2000rpm. solution, baked and annealed at 150°C for 15 minutes, and cooled naturally to obtain an anode modification layer. Then P3HT at a total concentration of 20 mg / mL was mixed with PC 60 A mixed solution of BM (with a mass ratio of 1:1) (the solvent is o-dichlorobenzene) was directly spin-coated on the above-mentioned anode modification layer at a speed of 800 rpm, and after solvent annealing, a photoelectric active layer was formed. Finally, at 5×10 -5 100nm-thick aluminum was vacuum-evaporated under Pascal as the cathode. In the obtained polymer solar cell, the thickness of PEDOT:PSS is The prepared device has an open circuit voltage of 0.55 volts, a short circuit current of 7.09 milliamperes per square centimeter, a fill fa...

Embodiment 2

[0037] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol, dried with nitrogen, and spin-coated with PEDOT:PSS at a speed of 2000rpm. solution, baked and annealed at 150°C for 15 minutes, and cooled naturally to obtain an anode modification layer. Then a PVDF solution with a concentration of 0.1 mg / mL (solvent is dimethylacetamide) was added to a total concentration of 20 mg / mL of P3HT and PC 60 BM (mass ratio is 1:1) in the mixed solution (solvent is o-dichlorobenzene) (in which PVDF solution and P3HT and PC 60 The volume ratio of the mixed solution of BM is 1:360), after being fully stirred, it is directly spin-coated on the above-mentioned anode modification layer at a speed of 800rpm, and after solvent annealing, a photoelectric active layer and a cathode modification layer are formed. Finally, at 5×10 -5 100nm-thick aluminum was vacuum-evaporated und...

Embodiment 3

[0039] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol, dried with nitrogen, and spin-coated with PEDOT:PSS at a speed of 2000rpm. solution, baked and annealed at 150°C for 15 minutes, and cooled naturally to obtain an anode modification layer. Then a PVDF solution with a concentration of 0.1 mg / mL (solvent is dimethylacetamide) was added to a total concentration of 20 mg / mL of P3HT and PC 60 BM (mass ratio is 1:1) in the mixed solution (solvent is o-dichlorobenzene) (in which PVDF solution and P3HT and PC 60 The volume ratio of the mixed solution of BM is 1:20), and it is directly spin-coated on the above-mentioned anode modification layer at a speed of 800 rpm, and after solvent annealing, a photoelectric active layer and a cathode modification layer are formed. Finally, at 5×10 -5 100nm-thick aluminum was vacuum-evaporated under Pascal as the cathod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com