ito particles

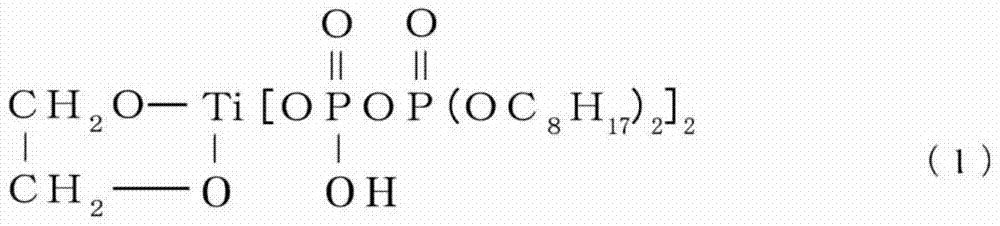

A particle, indium tin hydroxide technology, applied in the field of ITO particles, can solve problems such as the decline in the power generation efficiency of solar cells, and achieve the effect of reducing energy barriers and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

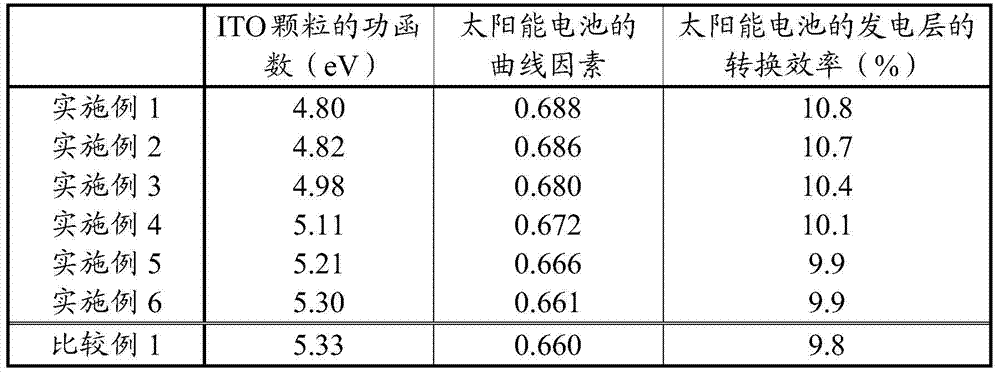

Embodiment 1

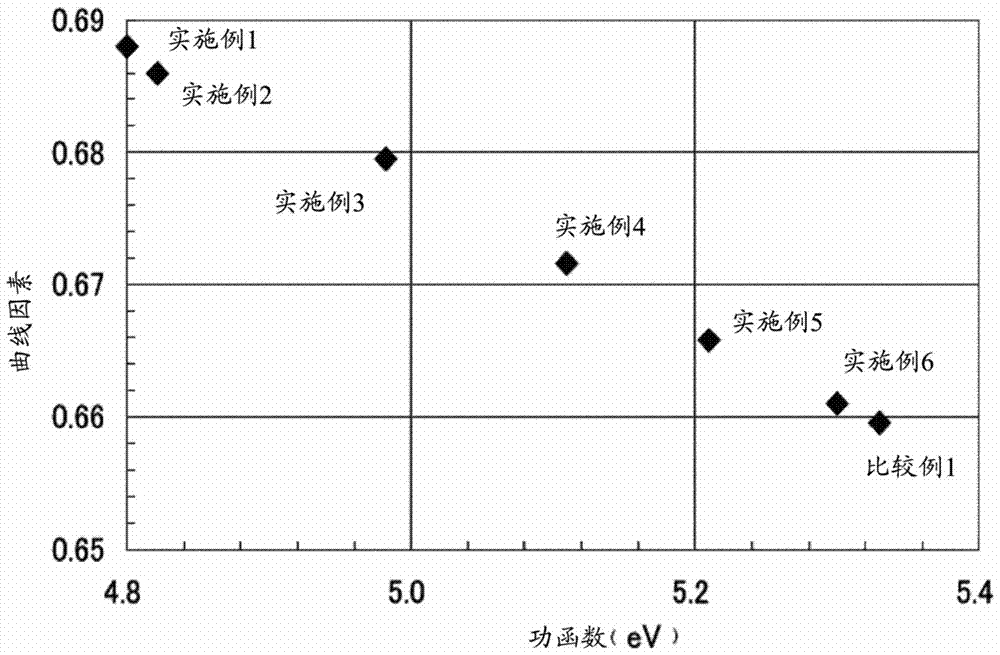

[0038] First, indium chloride (InCl) containing 18 g of In metal 3 ) aqueous solution 50mL and 0.36g of stannous chloride (SnCl 2 2H 2 O) Mix, and drop the mixed aqueous solution and ammonia (NH 3 ) aqueous solution to adjust to pH7. It was made to react for 30 minutes in the state which made the solution temperature into 30 degreeC. The generated indium tin co-precipitated hydroxide, that is, the precipitate, was washed repeatedly with ion-exchanged water. When the resistivity of the supernatant reaches more than 50000Ω·cm, discard the supernatant of the above-mentioned sediment, make a high-viscosity slurry, and use an ultraviolet irradiation device (Ushio Electric's Spot Cure SP- 9), select the DeepUV type, and make the central illumination of the irradiated liquid surface reach 50mW / cm 2 5 hours of UV rays are irradiated. Thereafter, the slurry-like indium tin hydroxide was dried overnight at 110° C. in the air, and then fired at 550° C. in the air for 3 hours to pul...

Embodiment 2

[0040] In Example 1, the condenser lens when the indium tin co-precipitated hydroxide slurry is irradiated with ultraviolet rays is set as a standard type, except that it is manufactured in the same way as in Example 1 to obtain the ITO particles of the present invention .

Embodiment 3

[0042] Indium chloride (InCl) containing 18g of In metal 3 ) aqueous solution 50mL and 0.6g stannous chloride (SnCl 2 2H 2 O) to mix, drop the mixed aqueous solution and ammonia (NH 3 ) aqueous solution to adjust to pH7. It was made to react for 30 minutes in the state which made the solution temperature into 30 degreeC. The generated indium tin co-precipitated hydroxide, that is, the precipitate, was washed repeatedly with ion-exchanged water. When the resistivity of the supernatant reaches more than 50000 Ω·cm, discard the supernatant of the precipitate to obtain slurry-like indium tin hydroxide. The slurry was diluted with absolute ethanol so that the solid content reached 1.0%, and the inside of the tubular furnace arranged vertically to the long side direction of the tube was sufficiently replaced with nitrogen gas, heated to 600°C, and the carrier gas, namely N 2 In the state where the gas is circulating inside the tubular furnace, the slurry-like indium tin hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com