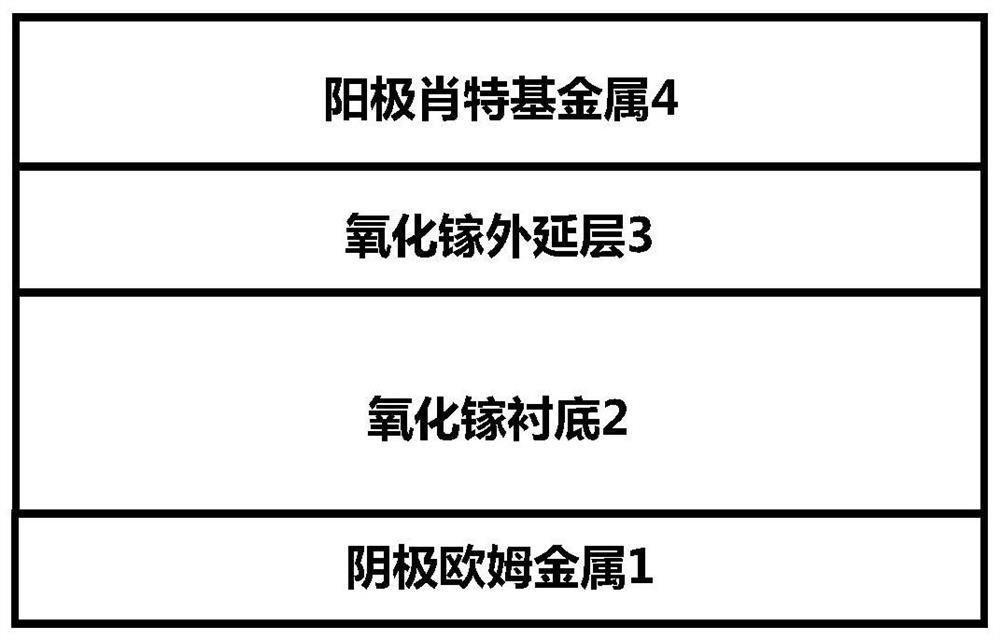

Preparation method of gallium oxide Schottky diode with low turn-on voltage

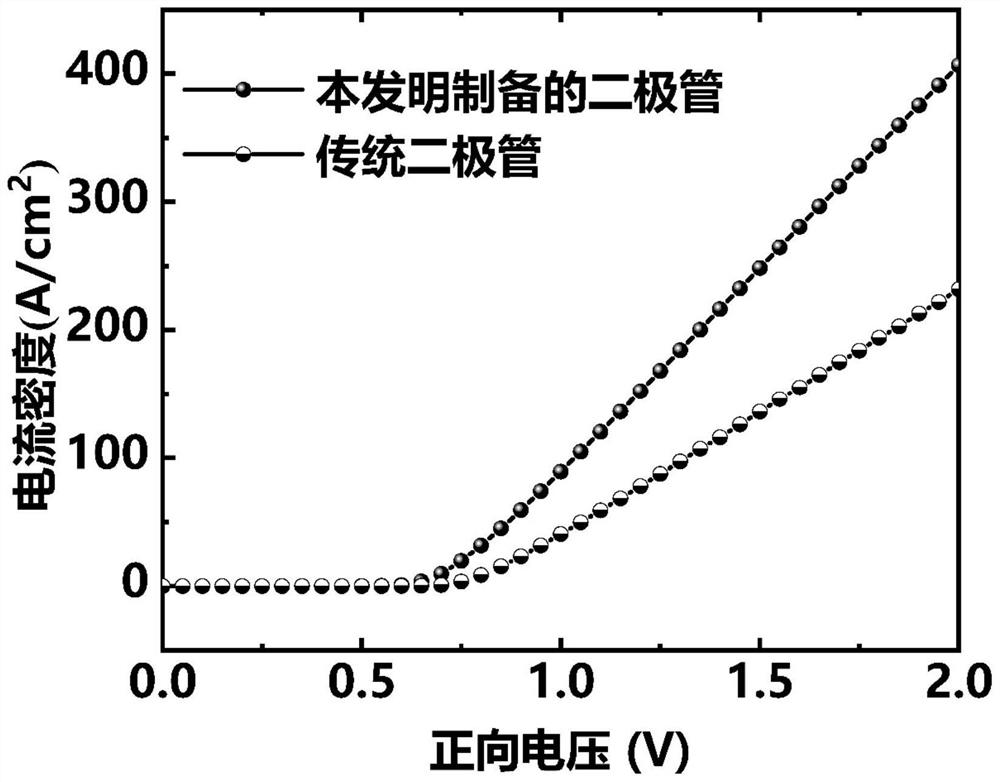

A Schottky diode and turn-on voltage technology, applied in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of high turn-on voltage, fast switching speed, low turn-on voltage, etc. On-resistance, the effect of reducing work function difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

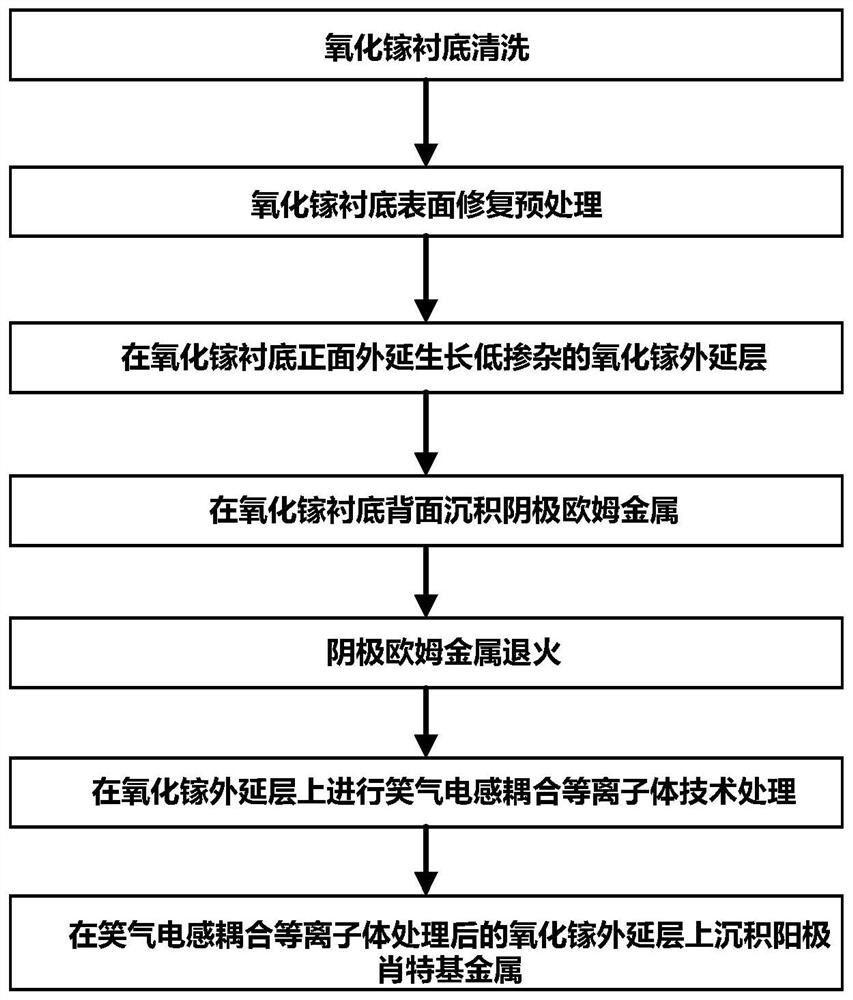

[0028] Embodiment 1: The thickness of the gallium oxide substrate is made to be 650 μm, and the effective doping carrier concentration is 10 18 cm -3 . The thickness of the lightly doped gallium oxide epitaxial layer is 10 μm, and the doping carrier concentration is 10 16 m -3 . Gallium oxide Schott for epitaxial layer gallium oxide (3) treated with laughing gas inductively coupled plasma under the conditions of power of 100W, nitrogen gas flow rate of 40sccm, pressure of 8mtorr, ambient temperature of 25°C, and treatment time of 2 minutes base diode.

[0029] Step 1: Gallium oxide substrate cleaning.

[0030] The gallium oxide substrate 2 is selected to have a thickness of 650 μm and an effective doping carrier concentration of 10 18 cm -3 , the doping ion species is Sn ion.

[0031] Use acetone-isopropanol-deionized water to sonicate for 5 minutes respectively, and then blow dry with nitrogen.

[0032] Step 2: performing repair pretreatment on the surface of the gal...

Embodiment 2

[0048] Embodiment 2: The thickness of the gallium oxide substrate is 300 μm, and the effective doping carrier concentration is 10 20 cm -3 , the thickness of the lightly doped gallium oxide epitaxial layer is 3 μm, and the doping carrier concentration is 10 17 m -3 . Under the conditions of power of 200W, nitrogen gas flow rate of 60sccm, pressure of 10mtorr, ambient temperature of 50°C, and treatment time of 4 minutes, epitaxial layer gallium oxide (3) was treated with laughing gas inductively coupled plasma. Teky diode.

[0049] Step 1: Gallium oxide substrate cleaning.

[0050] The selected thickness is 300 μm, and the effective doping carrier concentration is 10 20 cm -3 , a gallium oxide substrate 2 doped with Sn ions as the ion type, and ultrasonically ultrasonicated for 5 minutes using acetone-isopropanol-deionized water, respectively, and then blow-dried with nitrogen gas.

[0051] Step 2: Surface restoration pretreatment on gallium oxide substrate 2 .

[0052]...

Embodiment 3

[0062] Embodiment 3: The thickness of the gallium oxide substrate is 600 μm, and the effective doping carrier concentration is 10 18 cm -3 , the doping ion type is Sn ion, the thickness of the lightly doped gallium oxide epitaxial layer is 15 μm, and the doping carrier concentration is 10 16 m -3 , and the epitaxial layer of gallium oxide (3) was treated with laughing gas inductively coupled plasma under the conditions of power of 300W, nitrogen gas flow rate of 80sccm, pressure of 12mtorr, ambient temperature of 60°C, and treatment time of 6 minutes Schottky diodes.

[0063] Step A: gallium oxide substrate cleaning.

[0064] A1) The thickness of the gallium oxide substrate is selected as 600 μm, and the effective doping carrier concentration is 10 18 cm -3 , the dopant ion type is Sn ion;

[0065] A2) Use acetone-isopropanol-deionized water to sonicate for 5 minutes respectively, and then blow dry with nitrogen gas.

[0066] Step B: Pretreatment of the gallium oxide su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com