Preparation method of CaTi2O5tremella-like micro-nano structure photocatalyst and product prepared by method

A technology of micro-nano structure and photocatalyst, which is applied in the field of photocatalysis, can solve the problems of unfavorable industrial production, harsh process conditions and high equipment requirements, and achieve the effects of improving use value and economic benefits, strong controllability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

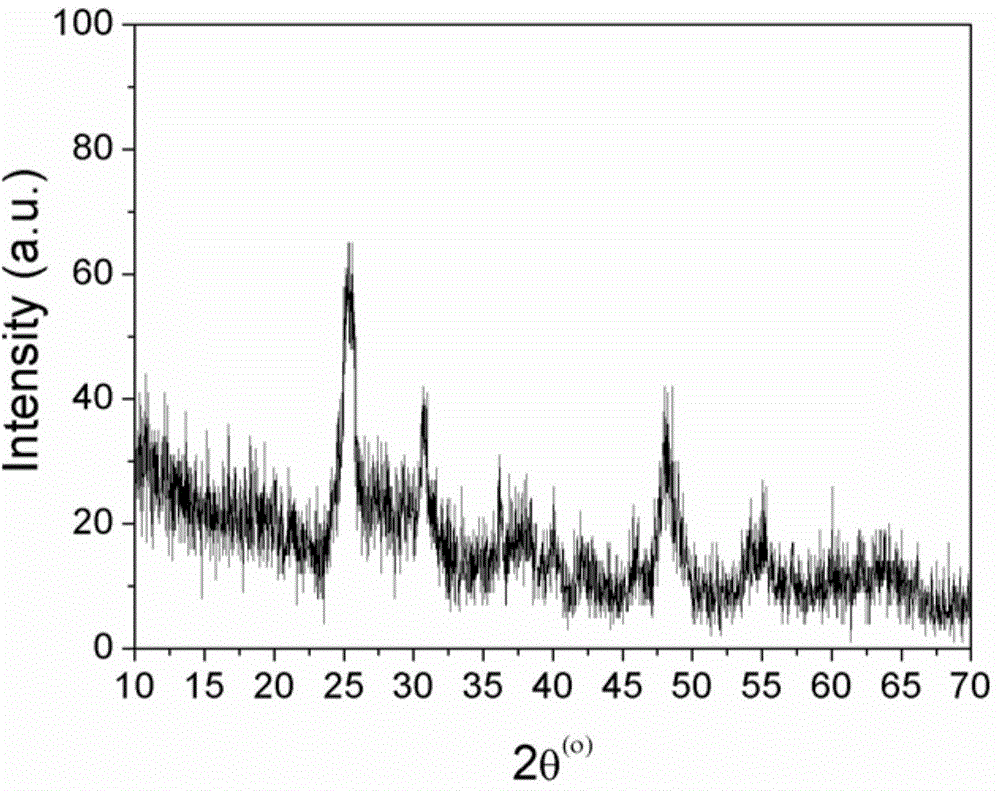

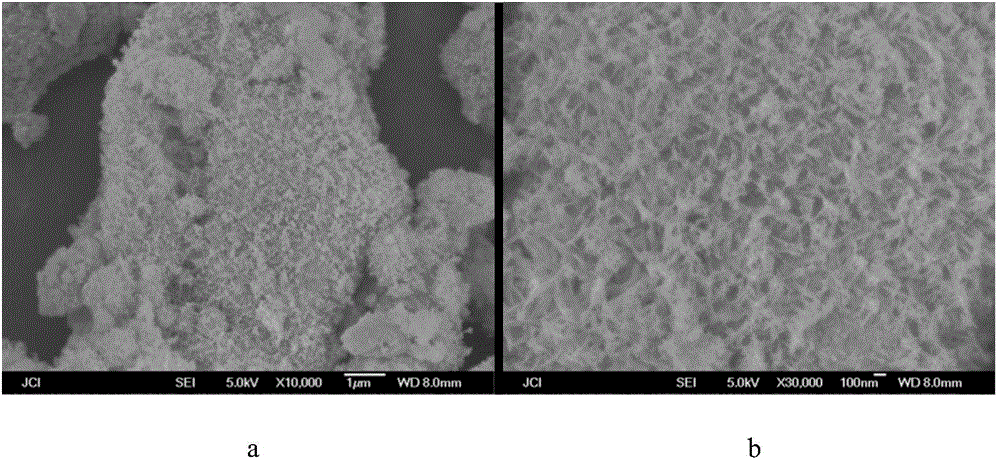

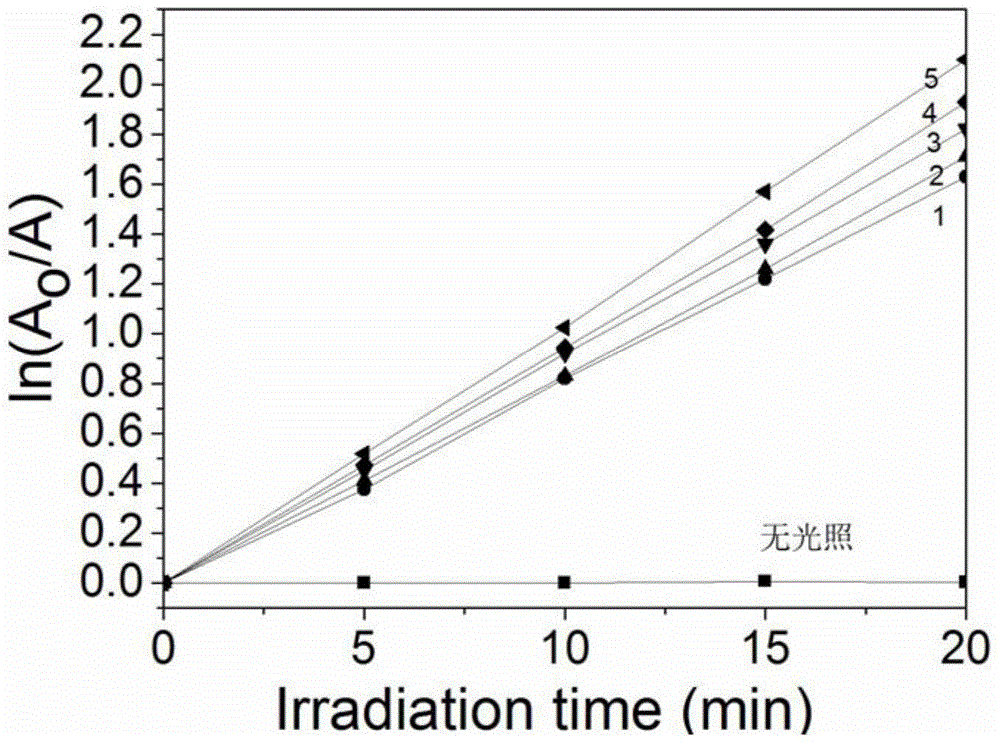

[0020] In this example, CaTi 2 o 5 The preparation method of the fungus-shaped micro-nano structure photocatalyst, the steps are as follows:

[0021] (1) Dissolve butyl titanate in ethanol, stir until uniform according to the molar ratio of butyl titanate: ethanol = 1:5, then add distilled water dropwise to produce a white precipitate, wash with distilled water, filter, and dry to obtain White powder A containing titanium;

[0022] (2) Dissolve calcium chloride dihydrate in distilled water, then add ethanol, stir until uniform to obtain liquid B; according to molar ratio calcium chloride dihydrate: distilled water: ethanol=1: 50: 10;

[0023] (3) According to the molar ratio of calcium chloride dihydrate: butyl titanate = 1: 1, the above liquid B is dripped into the powder A drop by drop under stirring state, and then the HCl solution is gradually added dropwise to adjust the pH value of the system to 2, Continue to stir for 15 minutes and mix, then put it in a hydrothermal...

Embodiment 2

[0025] In this example, CaTi 2 o 5 The preparation method of the fungus-shaped micro-nano structure photocatalyst, the steps are as follows:

[0026] (1) Dissolve isopropyl titanate in propanol, according to the molar ratio of isopropyl titanate: propanol = 1:6, stir until uniform, then add distilled water drop by drop to produce white precipitate, wash with distilled water, filter , after drying, white powder A containing titanium is obtained;

[0027] (2) Calcium chloride dihydrate is dissolved in distilled water, then propanol is added, and stirred until uniformly to obtain liquid B; according to the molar ratio of calcium chloride dihydrate: distilled water: propanol=1: 50: 5;

[0028] (3) According to the molar ratio of calcium chloride dihydrate: isopropyl titanate = 1: 1.2, drop the above liquid B into the powder A dropwise under stirring, and then gradually add HCl solution dropwise to adjust the pH of the system to 3 , continue to stir for 15 minutes, put it in a h...

Embodiment 3

[0030] In this example, CaTi 2 o 5 The preparation method of the fungus-shaped micro-nano structure photocatalyst, the steps are as follows:

[0031] (1) Dissolve titanium chloride in butanol, stir until uniform according to the molar ratio of titanium chloride: butanol=1:10, then add distilled water dropwise to produce a white precipitate, wash with distilled water, filter, and dry to obtain White powder A containing titanium;

[0032] (2) Dissolve calcium chloride dihydrate in distilled water, then add butanol, stir until uniform to obtain liquid B; according to the molar ratio calcium chloride dihydrate: distilled water: butanol=1: 400: 5;

[0033] (3) According to the molar ratio of calcium chloride dihydrate: titanium chloride = 1: 1.5, drop the above liquid B into the powder A drop by drop under stirring, then gradually add HCl solution dropwise to adjust the pH value of the system to 4, continue After stirring for 10 minutes, put it in a hydrothermal kettle and keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com