Preparation method of Sb2Se3 solar cell based on SnO2 buffer layer

A technology for solar cells and buffer layers, applied in coatings, circuits, electrical components, etc., can solve the problems of difficult control of SnO2 deposition rate, poor uniformity, and generation of waste liquid and harmful gases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

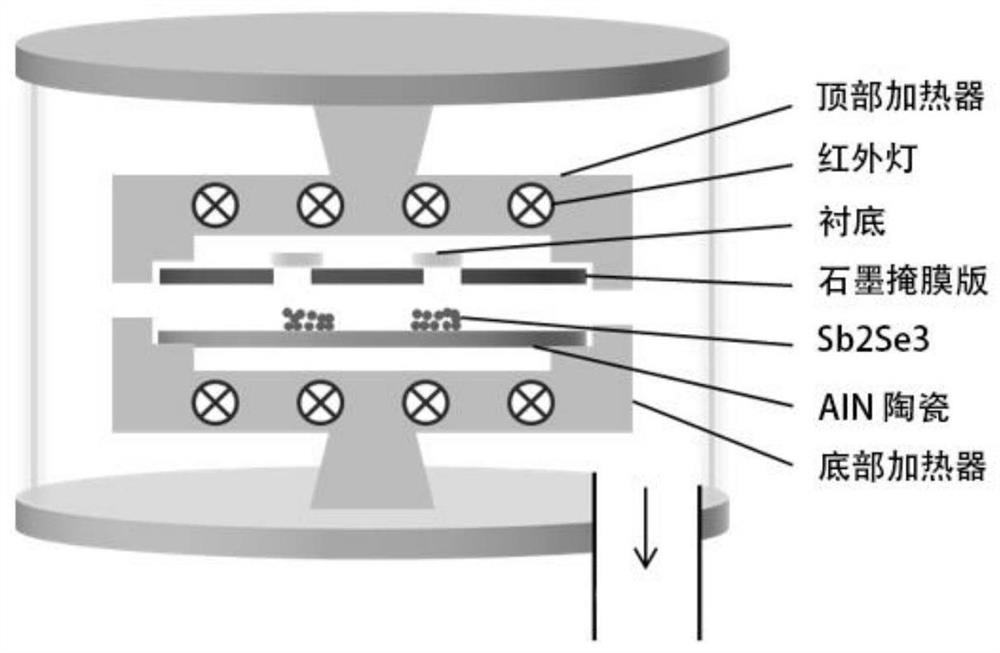

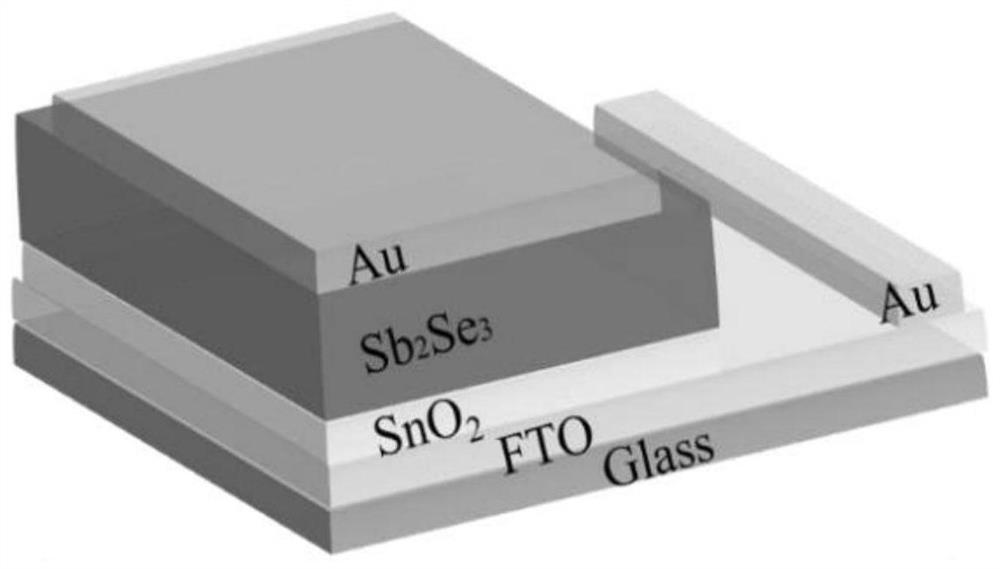

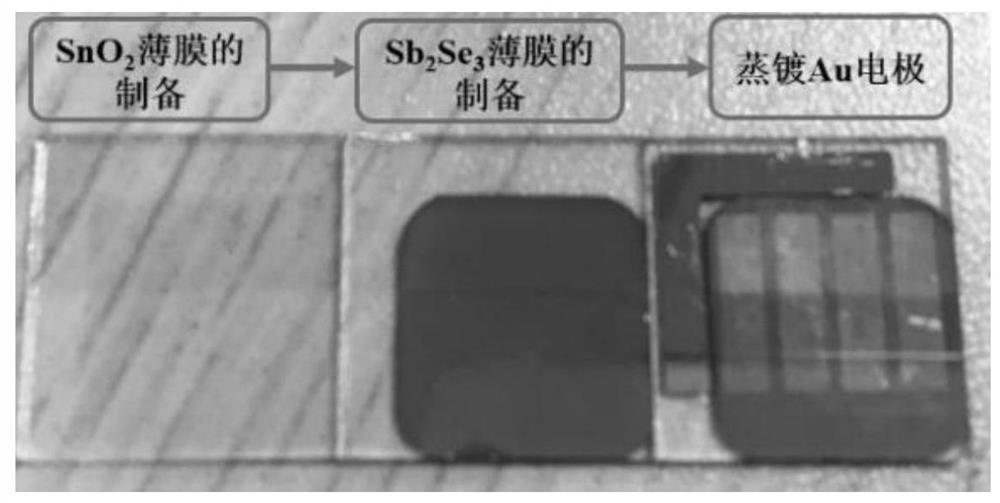

[0041] Further, the drawings are further described with reference to the present invention:

[0042] (1) Selection and cleaning of the substrate:

[0043] Shenzhen South China Xiangcheng Technology Co., Ltd. used by the present invention is 15 × 15mm 2 , FTO conductive glass having a thickness of 185 nm. The FTO conductive glass is placed in a 200 ml beaker, sequentially with acetone, water absolute ethanol, deionized water ultrasound washed 20 to 30 minutes, and then dry the ultrasonic cleaning FTO conductive glass is blown with high pressure nitrogen, and put it in a dust-free cloth. In the glass container, the cleaning of the clean FTO should be used as soon as possible to avoid secondary pollution in a long time.

[0044] (2) SNO 2 Preparation of the buffer layer:

[0045] The present invention adopts the MSP-300BT magnetron-controlled sputter coating machine of Beijing Chuangweiner Technology Co., Ltd., fixing the FTO glass substrate after cleaning on the sample stage, put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com