Apparatus and method for processing organic wastewater by using TiO2-based photocatalytic composite-electrode fuel cell

A fuel cell and composite electrode technology, applied in the field of TiO2-based photocatalytic composite electrode fuel cell treatment of organic wastewater, can solve the problems of organic pollutant oxidation, lack of long-term stability of microbial fuel cells, etc., to achieve effective treatment and promote degradation The effect of speed and utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

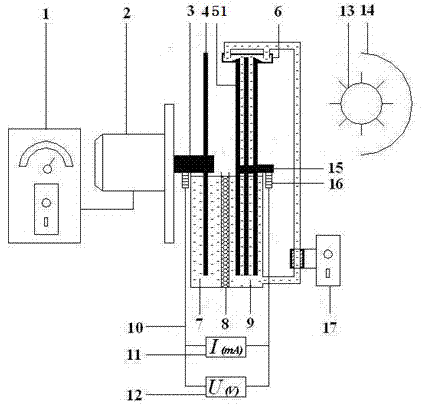

[0034] Monolithic interlayer photoanodes of TiO 2 The structure of the photocatalytic composite electrode fuel cell device.

[0035] A monolithic interlayer photoanode of TiO 2 The basic photocatalytic composite electrode fuel cell device includes a governor 1, a driving motor 2, a photocathode rotating shaft 3, a photocathode rotating disk 4, an interlayer photoanode 51, a sealed overflow tank 6 and a photoanode support frame 15, and a fuel cell reaction cell And the excitation light source, wherein the fuel cell reaction cell comprises a photoanode reaction cell 9, a photocathode reaction cell 7 and an ion exchange membrane 8, and the photoanode reaction cell 9 and the photocathode reaction cell 7 are connected by an ion exchange membrane 8, and the ion The exchange membrane is a cation exchange membrane or a composite ion exchange membrane. The interlayer photoanode 51 includes an interlayer photoanode base and a quartz glass shell, the interlayer photoanode base is recta...

Embodiment 2

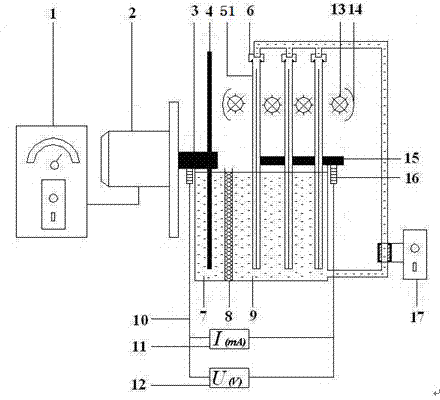

[0038] Multi-chip interlayer photoanode of TiO in series 2 The structure of the photocatalytic composite electrode fuel cell device.

[0039] A kind of TiO with multi-chip interlayer photoanode in series 2 A photocatalytic composite electrode fuel cell device, including a governor 1, a drive motor 2, a photocathode rotating shaft 3, a photocathode rotating disk 4, a multi-piece interlayer photoanode 51 in series, a sealed overflow tank 6, a fuel cell reaction cell and an excitation light source , wherein the fuel cell reaction cell includes a photoanode reaction cell 9, a photocathode reaction cell 7 and an ion exchange membrane 8, and the photoanode reaction cell 9 and the photocathode reaction cell 7 are connected by an ion exchange membrane 8, and the ion exchange membrane is Cation exchange membrane or composite ion exchange membrane. The interlayer photoanode 51 includes an interlayer photoanode base and a shell, the shell is quartz glass, the interlayer photoanode is r...

Embodiment 3

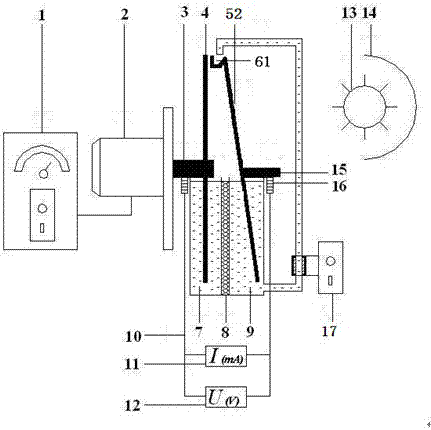

[0042] TiO monolithic slanted plate photoanode 2 The structure of the photocatalytic composite electrode fuel cell device.

[0043] A monolithic tilted plate photoanode of TiO 2 The basic photocatalytic composite electrode fuel cell device includes a governor 1, a drive motor 2, a photocathode rotating shaft 3, a photocathode turntable 4, a slant plate photoanode 52, a water pump 17, a fuel cell reaction pool and an excitation light source, wherein the fuel cell reaction The pool includes a photoanode reaction cell 9, a photocathode reaction cell 7, and an ion exchange membrane 8. The photoanode reaction cell 9 and the photocathode reaction cell 7 are connected by an ion exchange membrane 8, and the ion exchange membrane is a cation exchange membrane or a composite ion exchange membrane. The base of the inclined plate photoanode 52 is rectangular, and the base material is titanium, stainless steel, nickel or boron-doped diamond, and the material of the photocathode rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com