A kind of mesoporous nano quantum dot perovskite solar cell and preparation method

A technology of solar cells and nano-quantum dots, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as increasing sunlight transmission paths, uneven sunlight absorption, and increasing sunlight absorption, and achieves a simple and controllable production process , Improve conversion efficiency, improve the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

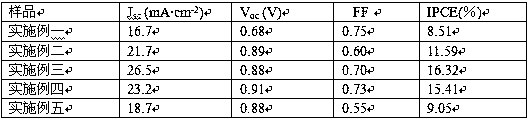

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] (1) Preparation of TiO 2 dense electron transport layer

[0035]First, clean the clear FTO glass. The FTO glass with a size of 2.0×2.0cm was first cleaned with detergent to remove surface oil and particulate pollutants, then ultrasonically cleaned with deionized water, acetone and alcohol for 15 minutes, and then dried with nitrogen to remove residual organic matter on the surface of the FTO glass .

[0036] Next, using radio frequency magnetron sputtering method, in an argon atmosphere with a purity of 99.99%, control the sputtering pressure to 0.1, sputtering power to 100W, deposit at room temperature for 10 minutes, put it into an atmosphere annealing furnace for 300-500 ℃, 0.5h-2h annealing under 10 Pa gas conditions, dense TiO can be obtained on FTO 2 electron transport layer.

[0037] (2) Preparation of mesoporous nanoflower ZnS quantum dot layer

[0038] First, take zinc acetate, Na 2 S 2 o 3 , EDTA,...

Embodiment 2

[0046] This embodiment includes the following steps:

[0047] (1) Preparation of ZnO dense electron transport layer

[0048] First, clean the transparent ITO glass. The ITO glass with a size of 3.0×3.0cm was first cleaned with detergent to remove surface oil and particle pollutants, then ultrasonically cleaned with deionized water, acetone and alcohol for 15 minutes, and then dried with nitrogen to remove residual organic matter on the surface of the ITO glass .

[0049] Then the ZnO dense electron transport layer was prepared by radio frequency magnetron sputtering (RF), the ITO glass substrate was placed in the sputtering chamber, and the pressure of the sputtering chamber was pumped to 2.5×10 -4 Pa, the argon gas with a purity of 99.9% was introduced, and after two washes, the sputtering pressure was controlled at 0.1Pa, and the sputtering power was 500W. A dense ZnO electron transport layer was obtained on ITO.

[0050] (2) Preparation of mesoporous nanoflower ZnS quan...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] (1) Preparation of ZnO dense electron transport layer

[0061] First, clean the transparent ITO glass. The ITO glass with a size of 3.0×3.0cm was first cleaned with detergent to remove surface oil and particle pollutants, then ultrasonically cleaned with deionized water, acetone and alcohol for 15 minutes, and then dried with nitrogen to remove residual organic matter on the surface of the ITO glass .

[0062] Then the ZnO dense electron transport layer was prepared by radio frequency magnetron sputtering (RF), the ITO glass substrate was placed in the sputtering chamber, and the pressure of the sputtering chamber was pumped to 2.5×10 -4 Pa, the argon gas with a purity of 99.9% was introduced, and after two washes, the sputtering pressure was controlled at 0.1Pa, and the sputtering power was 500W. A dense ZnO electron transport layer was obtained on ITO.

[0063] (2) Preparation of mesoporous nanoflower ZnS quan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com