Dielectric composite material and preparation method thereof and flat-plate type capacitor

A technology of composite materials and capacitors, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, electrospinning, etc., can solve the application limitations of high dielectric loss, low dielectric constant, intelligent and miniaturized electronic components etc. to achieve high dielectric properties, low dielectric loss, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

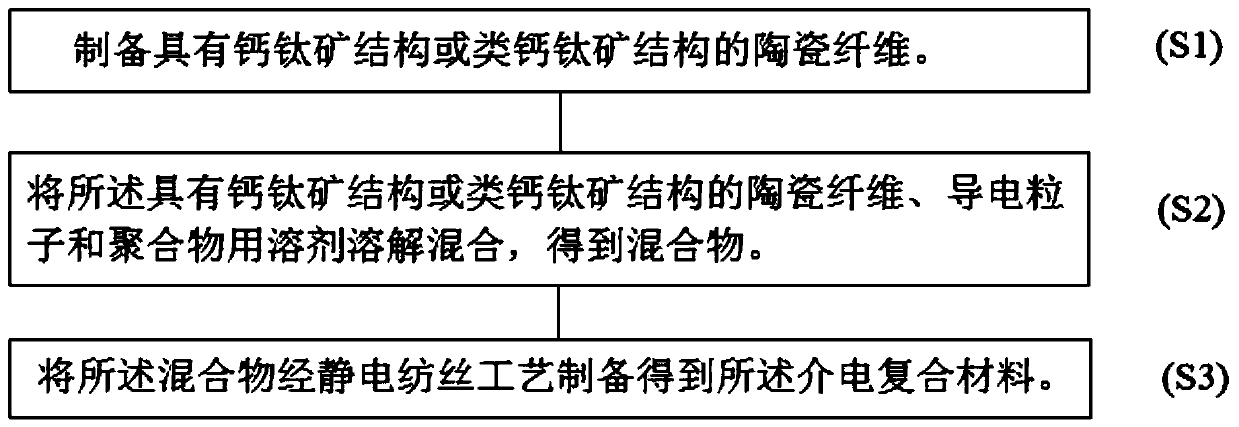

[0041] The present invention also provides the preparation method of above-mentioned dielectric composite material, such as figure 1 Shown, described preparation method comprises:

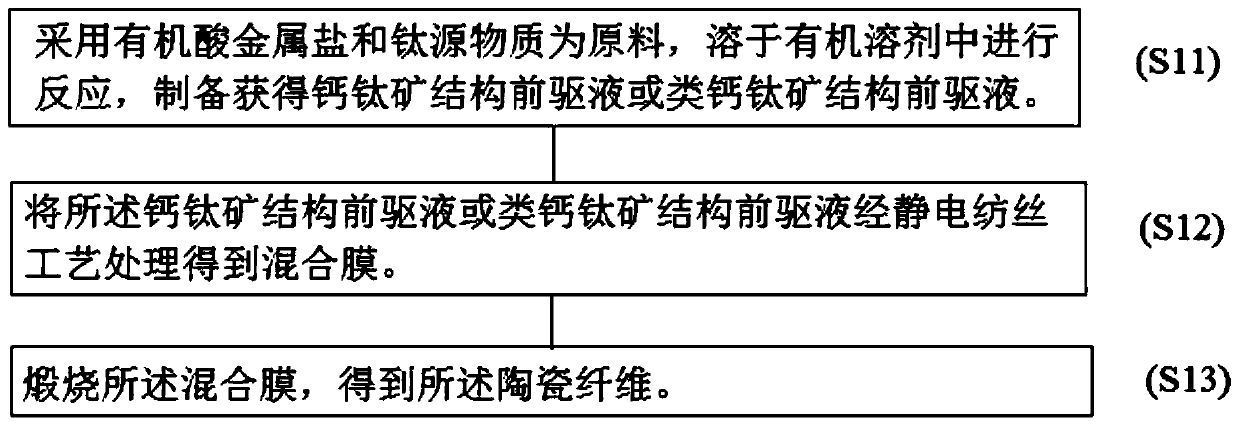

[0042] Step S1, preparing ceramic fibers having a perovskite structure or a perovskite-like structure. Such as figure 2 As shown, step S1 specifically includes:

[0043] In step S11, organic acid metal salt and titanium source material are used as raw materials, dissolved in an organic solvent and reacted to prepare a perovskite structure precursor or a perovskite-like structure precursor. The role of the organic solvent is to provide an environment for the reaction of the raw materials, while protecting the titanium source from hydrolysis.

[0044] The organic acid metal salt is at least one of strontium acetate, barium acetate, zirconium acetate, copper acetate and calcium acetate.

[0045] The titanium source material is titanate, titanium isopropoxide or titanium tetrachloride. Among them...

Embodiment 1

[0075] Preparation of ceramic fiber: Weigh 2.04328g of barium acetate and 0.82248g of strontium acetate, add 10mL of acetic acid and stir until the solution is clear and transparent to obtain solution A. In addition, 4.04328 g of tetrabutyl titanate and 2.40264 g of acetylacetone were weighed and stirred until the solution was clear and yellow and transparent, and solution B was obtained.

[0076] After mixing the two solutions of A and B, 1 g of polyvinylpyrrolidone (PVP) was added and stirred until the PVP was completely dissolved to obtain a perovskite-like structure precursor. Among them, the role of PVP is to increase the viscosity of the solution.

[0077] Under normal temperature conditions, the perovskite-like structure precursor solution was vacuum filtered for 10 minutes, and then treated by electrospinning process to obtain a mixed film. The parameters of the electrospinning process were: rotation speed 100r / min, voltage 8kV, The advancing speed is 0.02mm / min.

[...

Embodiment 2

[0088] Preparation of ceramic fiber: Weigh 2.04328g of barium acetate and 0.82248g of strontium acetate, add 10mL of acetic acid and stir until the solution is clear and transparent to obtain solution A. In addition, 4.04328 g of tetrabutyl titanate and 2.40264 g of acetylacetone were weighed and stirred until the solution was clear and yellow and transparent, and solution B was obtained. After mixing the two solutions of A and B, 1g of PVP was added and stirred until the PVP was completely dissolved to obtain a perovskite-like structure precursor.

[0089] Under normal temperature conditions, after vacuum filtration of the perovskite-like structure precursor solution for 10 minutes, the electrospinning process was used to obtain a mixed film. The parameters of the electrospinning process were: the rotational speed was 2800r / min, the voltage was 20kV, The advancing speed is 0.4mm / min.

[0090] After drying the mixed film formed by electrospinning, put it into a muffle furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com