Method for growing gallium phosphide single crystals

A growth method, gallium phosphide technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low yield, high dislocation density, unused industrial production, etc., achieve uniform crystal shape diameter, reduce Effect of Dislocation Density and Single Crystal Yield Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

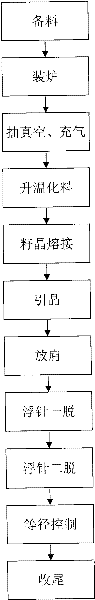

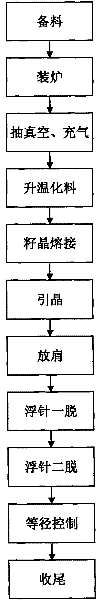

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation: Carry out vacuum dehydration on boron oxide, corrode gallium phosphide polycrystal with aqua regia and wash it with deionized water, treat the quartz vessel with aqua regia and wash it with deionized water.

[0024] 2. Material preparation: Put 1.0 kg of gallium phosphide polycrystalline that has been etched and cleaned into a quartz crucible, put a float boat with an inner diameter of φ30 mm in the center of the crucible, add 40 mg of dopant sulfur, and then put 200 g of smashed boron oxide into the crucible crucible.

[0025] 3. Furnace installation: Install the seed crystal, cross, floating needle and lens, adjust the verticality of the crucible rod with a dial indicator, configure the graphite heater and heat preservation parts, and place the quartz crucible with polycrystalline material in the graphite crucible In the wall, the furnace body is sealed.

[0026] 4. Use a vacuum pump to pump out the air in the furnace, and the final air pressure is le...

Embodiment 2

[0037] 1. Preparation: Carry out vacuum dehydration on boron oxide, corrode gallium phosphide polycrystal with aqua regia and wash it with deionized water, treat the quartz vessel with aqua regia and wash it with deionized water.

[0038] 2. Material preparation: Put 1.5 kg of gallium phosphide polycrystalline that has been etched and cleaned into a quartz crucible, put a float boat with an inner diameter of φ45 mm in the center of the crucible, add 80 mg of dopant sulfur, and then put 400 g of smashed boron oxide into the crucible crucible.

[0039] 3. Furnace installation: Install the seed crystal, cross, floating needle and lens, adjust the verticality of the crucible rod with a dial indicator, configure the graphite heater and heat preservation parts, and place the quartz crucible with polycrystalline material in the graphite crucible In the wall, the furnace body is sealed.

[0040] 4. Use a vacuum pump to pump out the air in the furnace, and the final air pressure is le...

Embodiment 3

[0051] 1. Preparation: Carry out vacuum dehydration on boron oxide, corrode gallium phosphide polycrystal with aqua regia and wash it with deionized water, treat the quartz vessel with aqua regia and wash it with deionized water.

[0052] 2. Material preparation: Put 2.0 kg of gallium phosphide polycrystalline that has been etched and cleaned into a quartz crucible, put a float boat with an inner diameter of φ55 mm in the center of the crucible, put 900 mg of dopant tellurium, and then put 500 g of smashed boron oxide into the crucible crucible.

[0053] 3. Furnace installation: Install the seed crystal, cross, floating needle and lens, adjust the verticality of the crucible rod with a dial indicator, configure the graphite heater and heat preservation parts, and place the quartz crucible with polycrystalline material in the graphite crucible In the wall, the furnace body is sealed.

[0054] 4. Use a vacuum pump to pump out the air in the furnace, and the final air pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com