Method for synthesizing magnetic metallic oxide Nano wire in high length-diameter ratio

A magnetic metal, high aspect ratio technology, applied in the direction of magnetic objects, magnetic materials, nanotechnology, etc., can solve the problem of inability to synthesize nanomaterials with aspect ratio, and achieve the effect of easy popularization and application, wide application and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

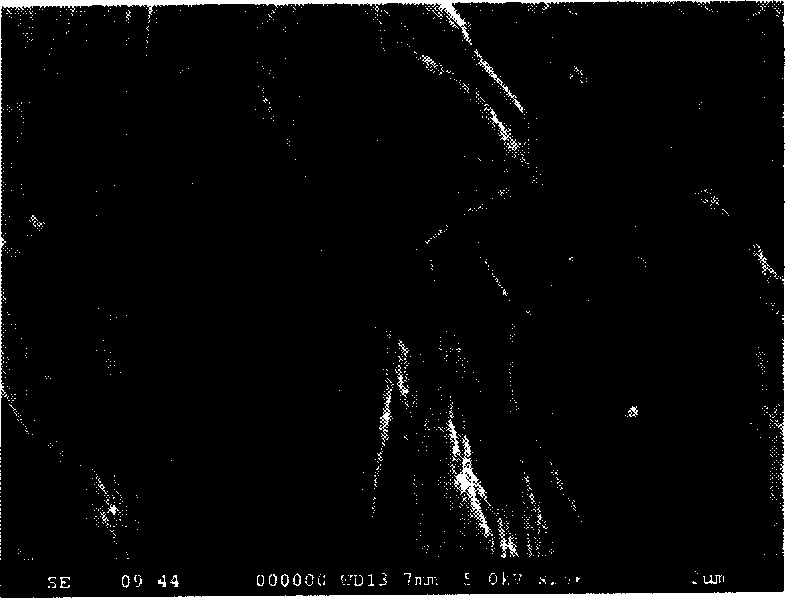

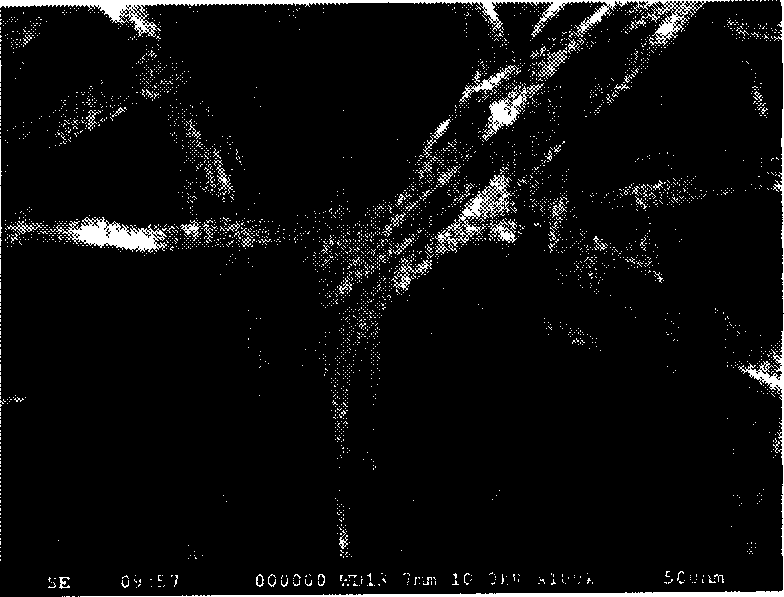

Image

Examples

Embodiment 1

[0024] Add 10ml of P123 alcohol solution to 250ml of water and mix evenly; then add 5ml of ethylene glycol and 1g of hexamethylenetetramine, and stir evenly; pass in nitrogen to exhaust oxygen, after heating up to 80°C, add FeCl at a certain speed 2 and FeCl 3 The mixed solution of which Fe in the system 2+ The concentration of ions is 1~4×10 - 3 mol.L -1 , Fe 3+ The concentration of ions is 2~8×10 -3 mol.L -1 , the addition rate is 1.7-2.5ml / min, the molar ratio of the two ions is 1:2, after several hours of continuous reaction, the reaction is stopped, and the temperature is lowered to room temperature. After precipitating, separating and washing under a magnetic field, dry at 60° C. for 12 hours, and carry out several times to separate and purify the one-dimensional material particles. The proportion of linear structure in the product is higher than 70%, the diameter of the nanowire is 10-15 nanometers, and the maximum aspect ratio can reach 500.

Embodiment 2

[0026] Add 20ml of PEG aqueous solution to 250ml of water and mix evenly; then add 10ml of ethylene glycol and 2g of hexamethylenetetramine, and stir evenly; pass in nitrogen to exhaust oxygen, heat up to 80°C, and then add FeSO at a certain speed 4 and FeCl 3 The mixed solution of which Fe in the system 2+ The concentration of ions is 1~4×10 -3 mol.L -1 , Fe 3+ The concentration of ions is 2~8×10 -3 mol.L -1 , the molar ratio of the two ions is 1:2, the addition rate is 2.5-4ml / min, after several hours of continuous reaction, stop the reaction and cool down to room temperature. After precipitating, separating and washing under a magnetic field, dry at 60° C. for 12 hours, and carry out several times to separate and purify the one-dimensional material particles. The obtained nanowire has a diameter of 20-30 nanometers and an aspect ratio of 50-300.

Embodiment 3

[0028]Add 20ml of PVA aqueous solution to 250ml of water and mix evenly; then add 20ml of ethylene glycol, 3g of hexamethylenetetramine, and stir evenly; through nitrogen exhaust, after heating up to 80°C, add manganese nitrate at a certain speed, Mixed solution of ferrous chloride and ferric chloride (molar ratio Mn 2+ : Fe 2+ : Fe 3+ =1:1:4), wherein the concentration of divalent metal ions in the system is 2~4×10 -3 mol.L 1 , the concentration of trivalent Fe ions is 4~8×10 -3 mol.L -1 , the addition rate is 1.2-1.7ml / min, after several hours of continuous reaction, stop the reaction and cool down to room temperature. After separating and washing under a magnetic field, dry at 60° C. for 12 hours, and carry out several times to separate and extract one-dimensional material particles. The obtained nanowire has a diameter of 20-30 nanometers and an aspect ratio of 10-150.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com