Preparation method of graphene-carbon nanotube composite fiber with helical structure

A carbon nanotube composite and helical structure technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, and inorganic raw material artificial filaments, etc., can solve the problems of difficulty in achieving large size and insufficient mixing of graphene and carbon nanotube composite fibers. , to achieve the effect of continuous and uniform fiber morphology and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: graphene solution can be prepared according to the method comprising the following steps: a certain amount of expanded graphite is dissolved in the mixed solution of sulfuric acid and phosphoric acid, after stirring, slowly add a certain amount of permanganate under ice bath conditions Potassium particles, after the reaction is complete, add deionized water to dilute, and add hydrogen peroxide to fully oxidize, then use acid and water to repeatedly centrifugally clean the reactants, and finally prepare a uniformly distributed graphene oxide solution. The steps are as follows:

[0047] (1) Take 200ml of sulfuric acid and 50ml of phosphoric acid, mix them evenly in a 1-liter beaker, and add 3 grams of worm graphite of about 300 mesh.

[0048] (2) Slowly add 20 grams of potassium permanganate particles under ice bath conditions.

[0049] (3) Under the condition of 40℃ water bath, react for 4 hours.

[0050] (4) Slowly add 700ml of deionized water into the be...

Embodiment 2

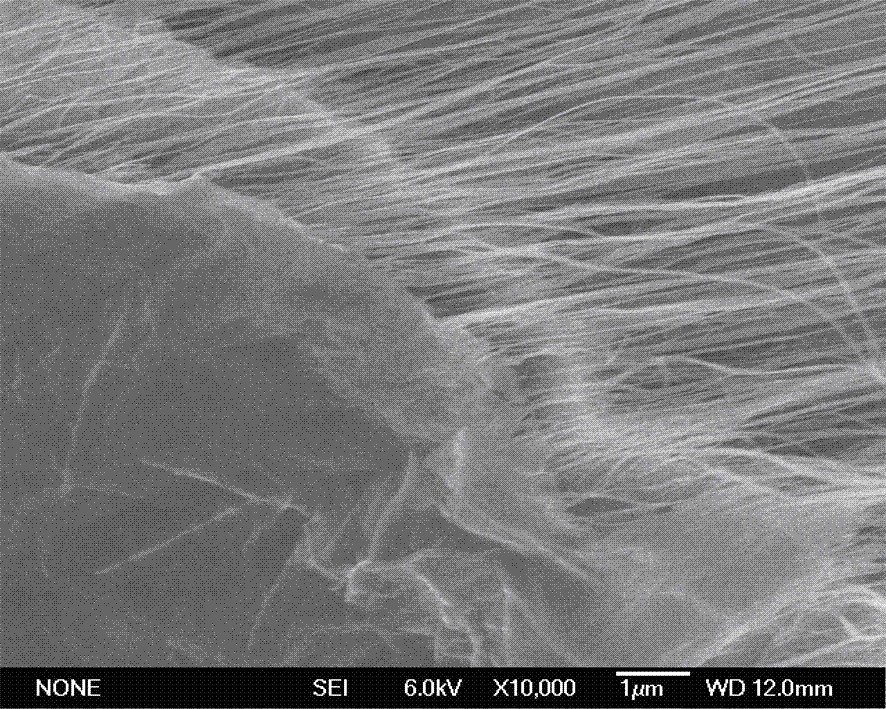

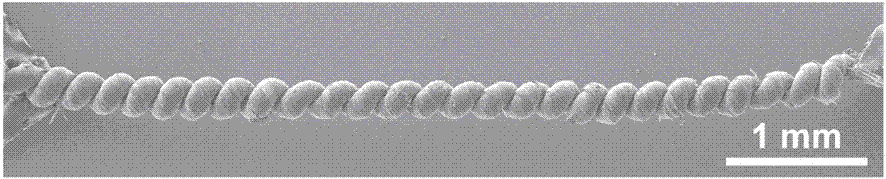

[0054] Take a graphene oxide aqueous solution with a concentration of 5 mg / mL, and then prepare a continuously grown carbon nanotube film by chemical vapor deposition, and mix the continuous carbon nanotube film with the graphene oxide solution layer by layer, continuously After collecting for 1 h, a uniform, layered and flexible graphene oxide-carbon nanotube composite film was obtained. After natural drying, the composite film was cut into strips (3 mm) with adjustable width, which were rotated and spun by the rotation of a motor in a humid environment to obtain helical graphene oxide-carbon nanotube helical fibers , followed by chemical reduction with hydriodic acid to obtain graphene-carbon nanotube helical fibers. The helical structure is observed by a scanning electron microscope (model JEOL JSM-6700), and its diameter is about 250-300 microns.

[0055] The preparation method of graphene solution in the present embodiment is the same as embodiment 1.

Embodiment 3

[0057] Take a graphene oxide aqueous solution with a concentration of 5 mg / mL, and then prepare a continuously grown carbon nanotube film by chemical vapor deposition, and mix the continuous carbon nanotube film with the graphene oxide solution layer by layer, continuously After collecting for 1 h, a uniform, layered and flexible graphene oxide-carbon nanotube composite film was obtained. After natural drying, the composite film was cut into strips (4 mm) with adjustable width, which were rotated and spun by the rotation of a motor in a humid environment to obtain helical graphene oxide-carbon nanotube helical fibers , followed by chemical reduction with hydriodic acid to obtain graphene-carbon nanotube helical fibers. The helical structure is observed by a scanning electron microscope (model JEOL JSM-6700), and its diameter is about 300-350 microns.

[0058] The preparation method of graphene solution in the present embodiment is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com