Brazing ball machining device enabling size of brazing balls to be controllable and machining method

A processing device and brazing technology, used in manufacturing tools, metal processing equipment, welding media, etc., can solve the problems of large size of solder balls, little research, increase the production cost of electronic products, etc., achieve uniform diameter, and improve the degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

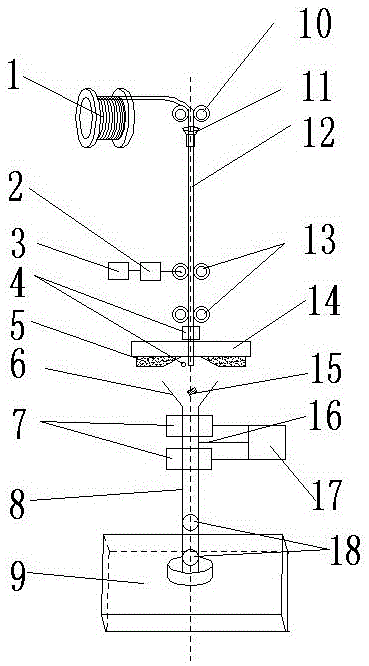

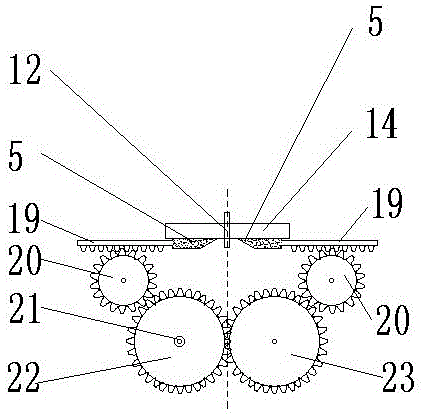

[0032] A brazing ball processing device capable of controlling the size of the brazing ball, comprising a wire feeding device, a wire cutting device and a heating and cooling device arranged sequentially from top to bottom, the solder wire 12 reaches the wire cutting device through the wire feeding device, and the After the blade 5 in the wire device cuts it off, the cut brazing material wire segment 15 falls into the heating and cooling device below the wire cutting device, and after being heated and melted, it is spheroidized and cooled to form a brazing ball, and finally falls into the brazing wire. In the feed ball groove 9.

[0033] The wire feeding device includes a brazing wire reel 1, a wire feeding roller 10, a positioning device 11 and a brazing wire length control device, and the wire feeding roller 10, the positioning device 11 and the brazing wire length control device are from top to bottom Arranged in sequence, the wire feeding roller 10 pulls out the brazing wi...

Embodiment 2

[0046] A brazing ball processing device capable of controlling the size of the brazing ball, on the basis of embodiment 1, the surface of the roller is a corrugated surface.

Embodiment 3

[0048] A solder ball processing device capable of controlling the size of solder balls. On the basis of Embodiment 1, the width of the inlet end of the positioning device 11 is greater than the width of the outlet end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com