Vacuum molding box

A technology of vacuum shaping and box body, which is applied to other household appliances, household appliances, applications, etc., can solve the problem of large spray water, etc., and achieve the effect of drying the surface of the pipe body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0045] Glossary explanation: A direction refers to clockwise or counterclockwise.

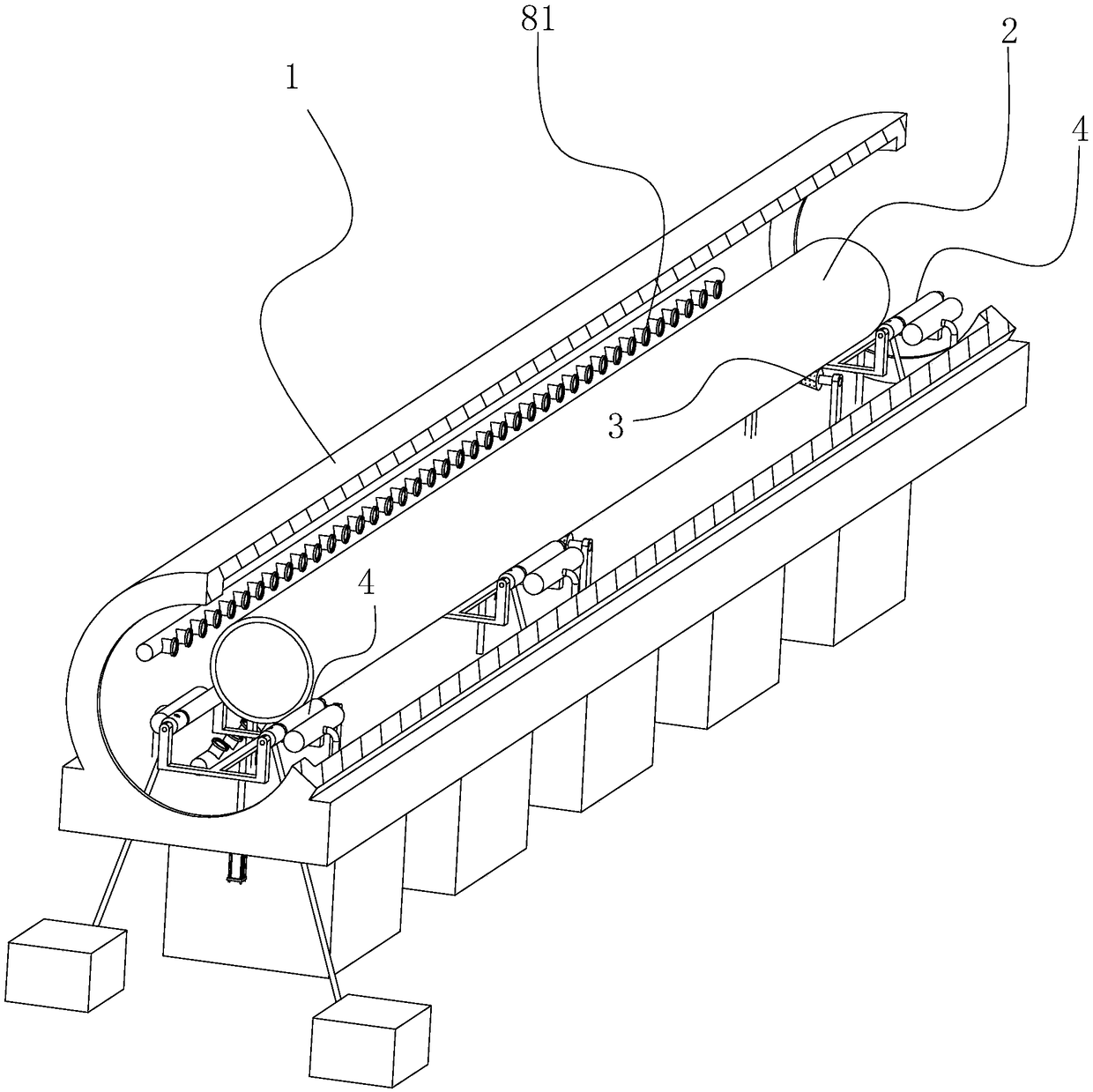

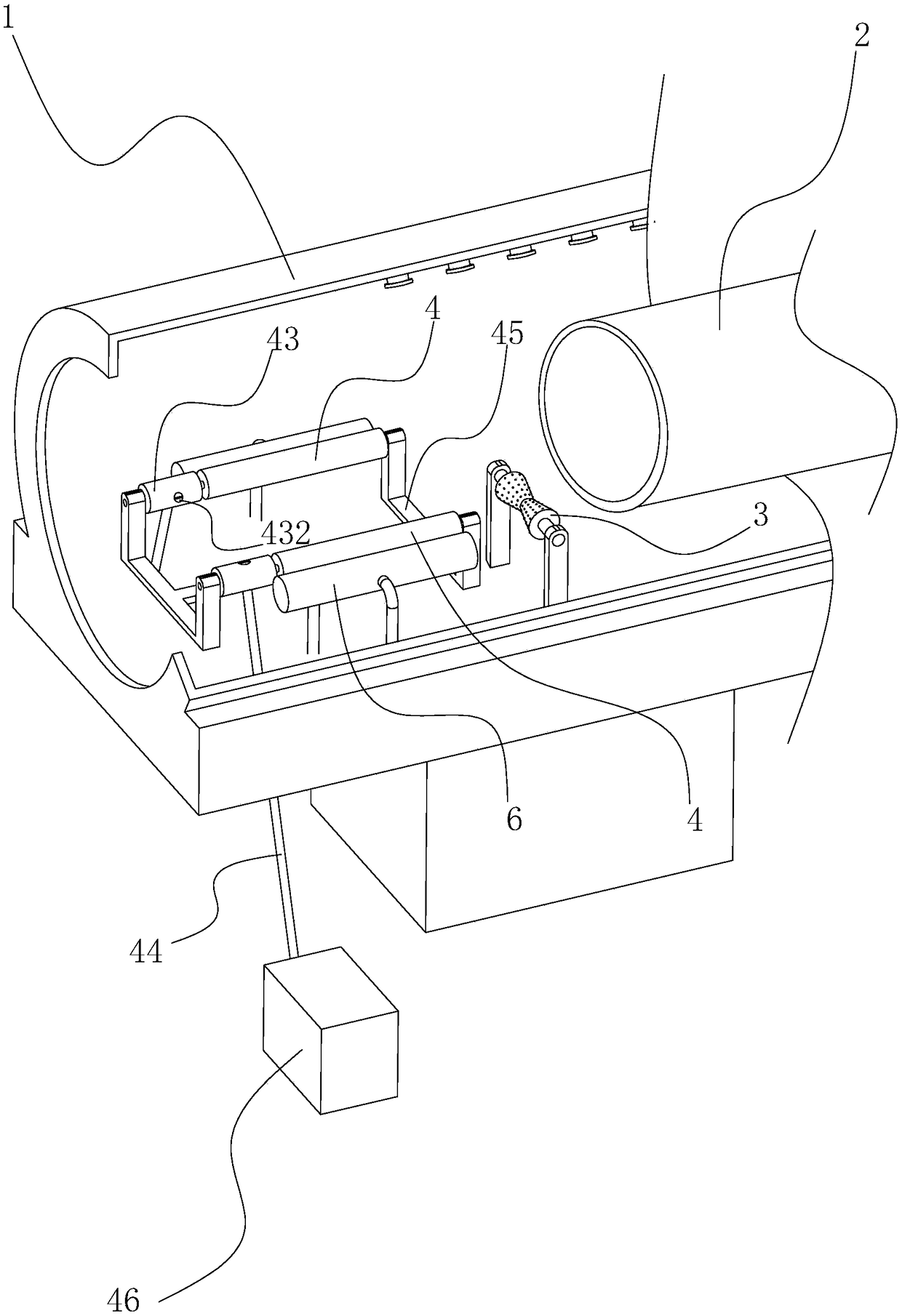

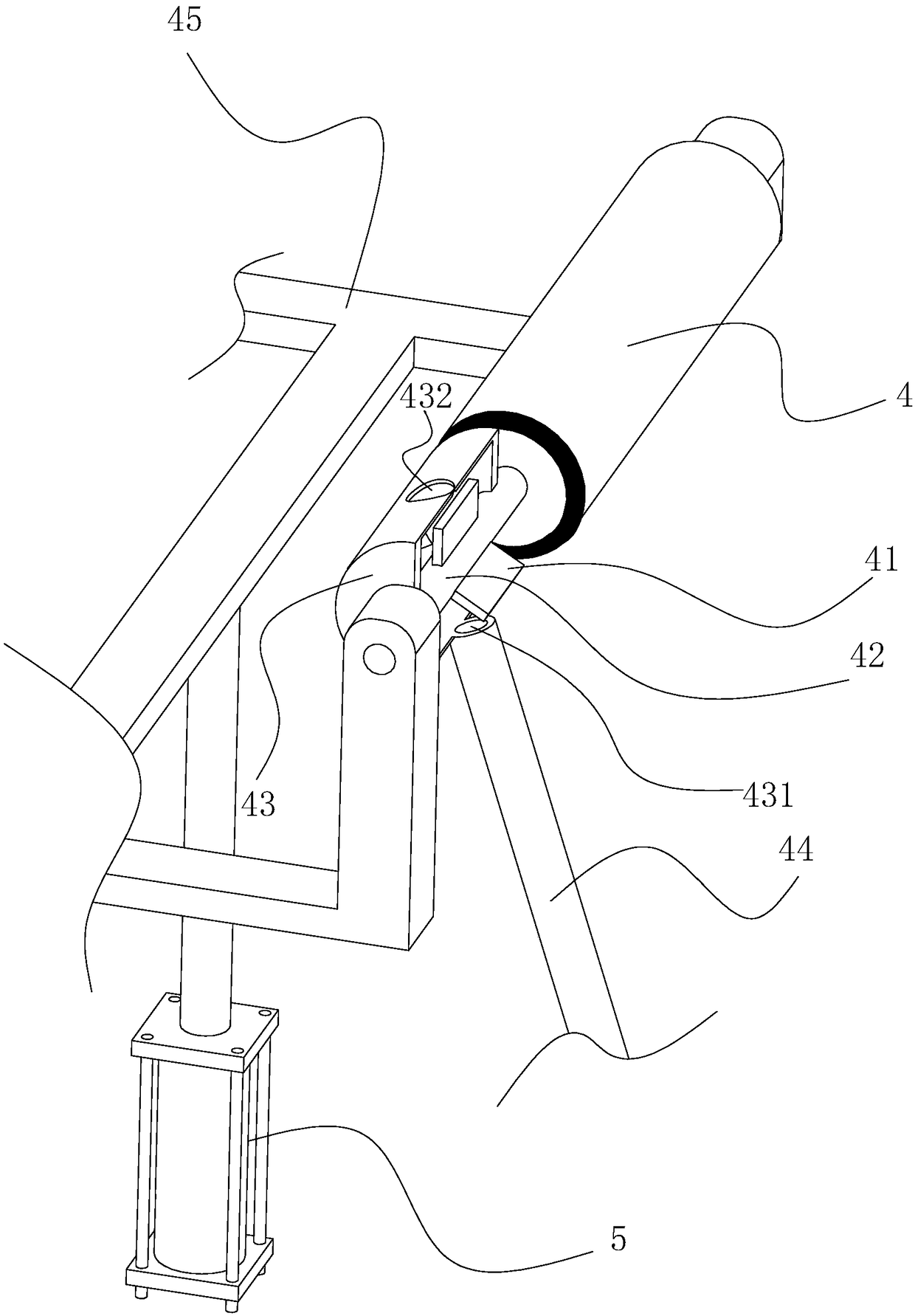

[0046] Example, a vacuum calibrator such as figure 1 As shown, including a cylindrical box body 1, a sealing cover will be installed at both ends of the box body 1, and the sealing cover can be locked on the box body 1 by buckling or other methods. Of course, the sealing cover can freely open and close the box body 1 ; Through the sealing effect of the sealing cover, the box body 1 will form a sealed chamber.

[0047] The end of the box body 1 is used for feeding the pipe body 2. The delivery roller 3 is installed in the box body 1. The delivery roller 3 supports the pipe body 2. The pipe body 2 is vacuum-shaped in the box body 1 and passed through the spray head. After the water of 81 is cooled, the pipe body 2 will still be pulled out of the box body 1 along the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com