Method for preparing magnetic metal particle modified carbon nanotube

A technology of carbon nanotubes and magnetic metals, which is applied in the field of preparation of carbon nanotubes modified by magnetic metal particles, can solve the problems of reducing material properties and destroying carbon tube structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The hydrogen flow rate of the carrier gas is 1.6cm / s, weigh 5 grams of the mixture of ferrocene and sulfur powder, wherein the weight ratio of ferrocene and sulfur powder is 100:1, the volatilization temperature is 200°C, and the reaction zone temperature is 1100°C , the heating rate is 20°C / min, and the temperature is kept for 5 minutes, and the final product is black powder.

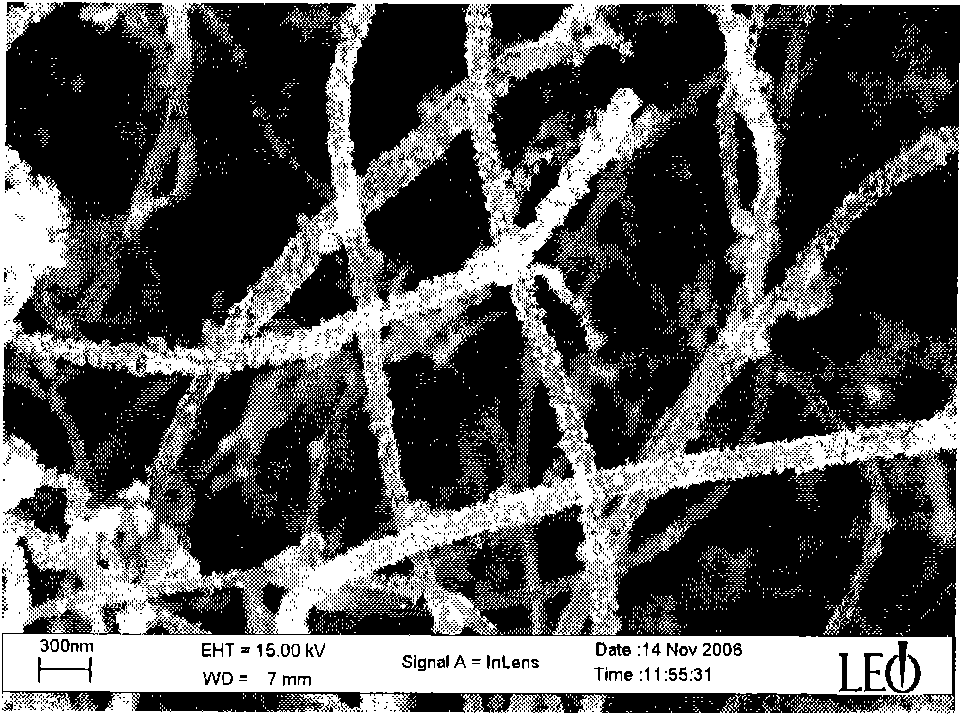

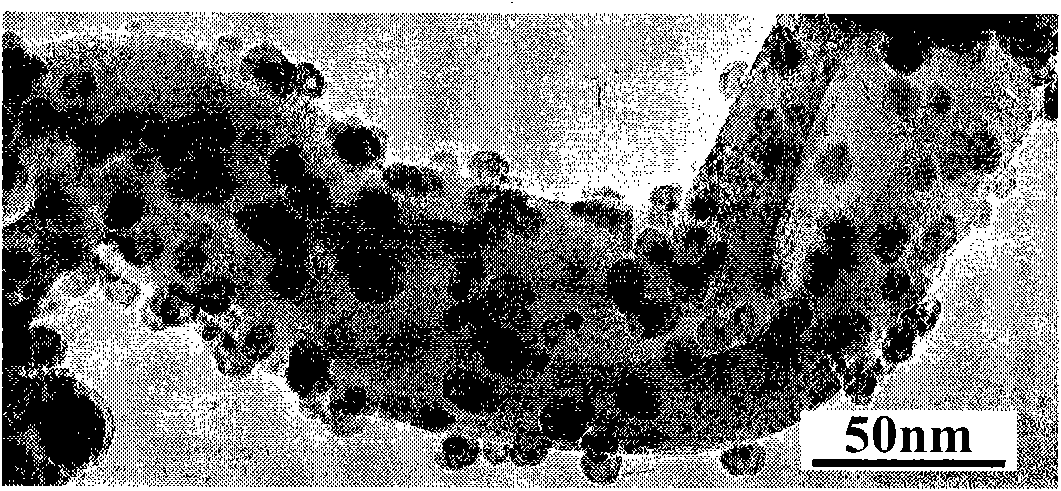

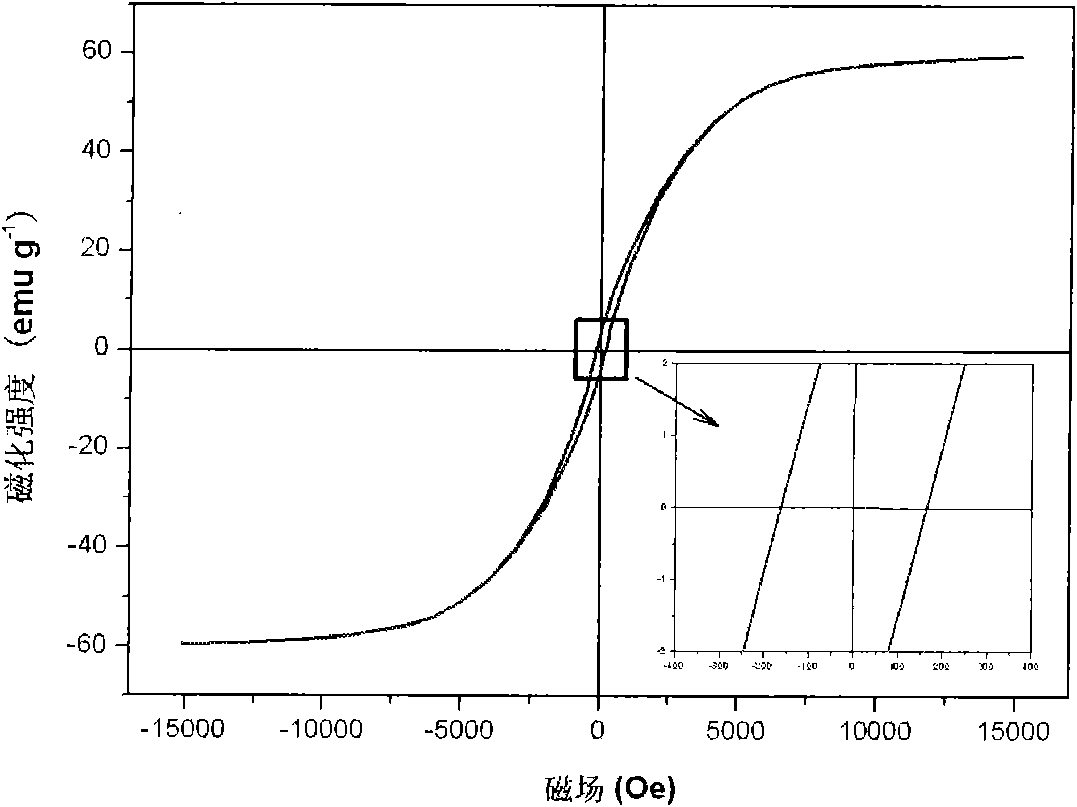

[0022] scanning( figure 1 ) and transmission electron microscopy ( figure 2 ) and magnetic analysis ( image 3 ) showed that the product was carbon nanotubes decorated with magnetic iron particles. In the present embodiment, the outer diameter of the carbon nanotube is 50-120nm, the inner diameter is 20-60nm, and the average diameter of the iron particles is ~ 10nm; the product is subjected to thermal analysis in air ( Figure 4 ) indicated that the content of metal particles in the product was ~32 wt%.

Embodiment 2

[0024] The carrier gas argon flow rate is 1.6cm / s, weigh 5 grams of the mixture of ferrocene and sulfur powder, wherein the weight ratio of ferrocene and sulfur powder is 100:1, the volatilization temperature is 250 °C, and the reaction zone temperature is 1100 °C, the heating rate is 30 °C / min, and the temperature is kept for 5 min, and the final product is in the form of black powder.

[0025] Scanning and transmission electron microscopy and magnetic analysis show that the product is carbon nanotubes decorated with magnetic iron particles. In this embodiment, the outer diameter of carbon nanotubes is 70-160nm, the inner diameter is 40-90nm, and the average diameter of iron particles is ~5nm; thermal analysis shows that the content of metal particles in the product is ~30wt%.

Embodiment 3

[0027] The flow rate of the carrier gas argon is 1.6cm / s, weigh 5 grams of the mixture of ferrocene and sulfur powder, wherein the weight ratio of ferrocene and sulfur powder is 50:1, the volatilization temperature is 150°C, and the reaction zone temperature is 900°C °C, the heating rate is 40 °C / min, and the heat preservation is 5 min, and the final product is black powder.

[0028] Scanning and transmission electron microscopy and magnetic analysis show that the product is carbon nanotubes decorated with magnetic iron particles. In this example, the outer diameter of the carbon nanotubes is 90-200nm, the inner diameter is 30-110nm, and the average diameter of the iron particles is ~45nm; thermal analysis shows that the content of the metal particles in the product is ~40wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com