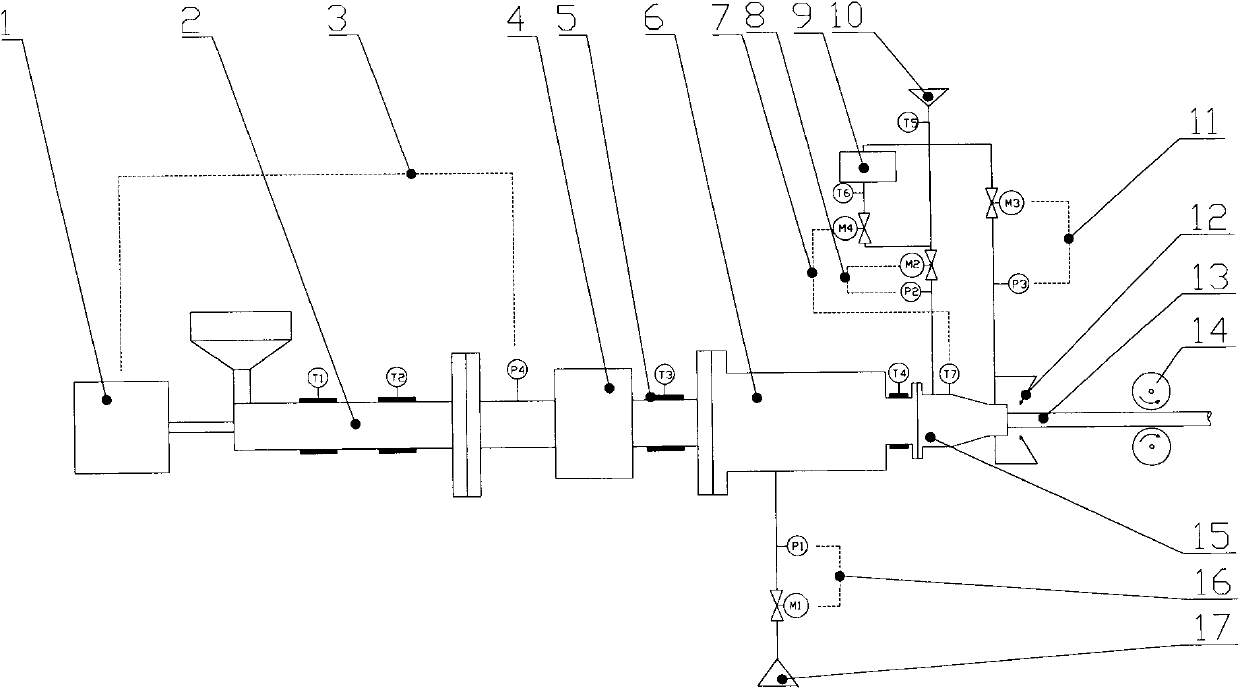

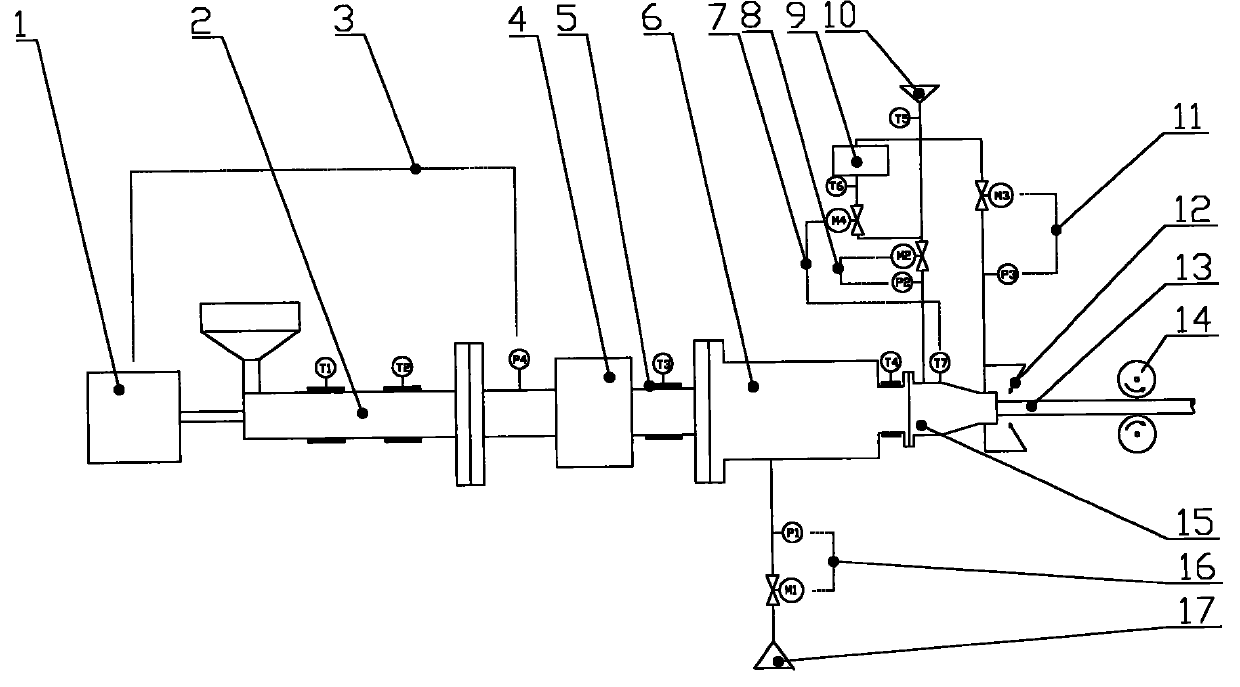

Physical foaming agent injected plastic extruded microchannel molding device and method

A technology of physical foaming agent and molding device, which is applied in the field of plastic extrusion molding processing, can solve the problems of high elongation rate, decreased roundness, limited effect, etc., and achieve the effects of high stability, easy operation, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

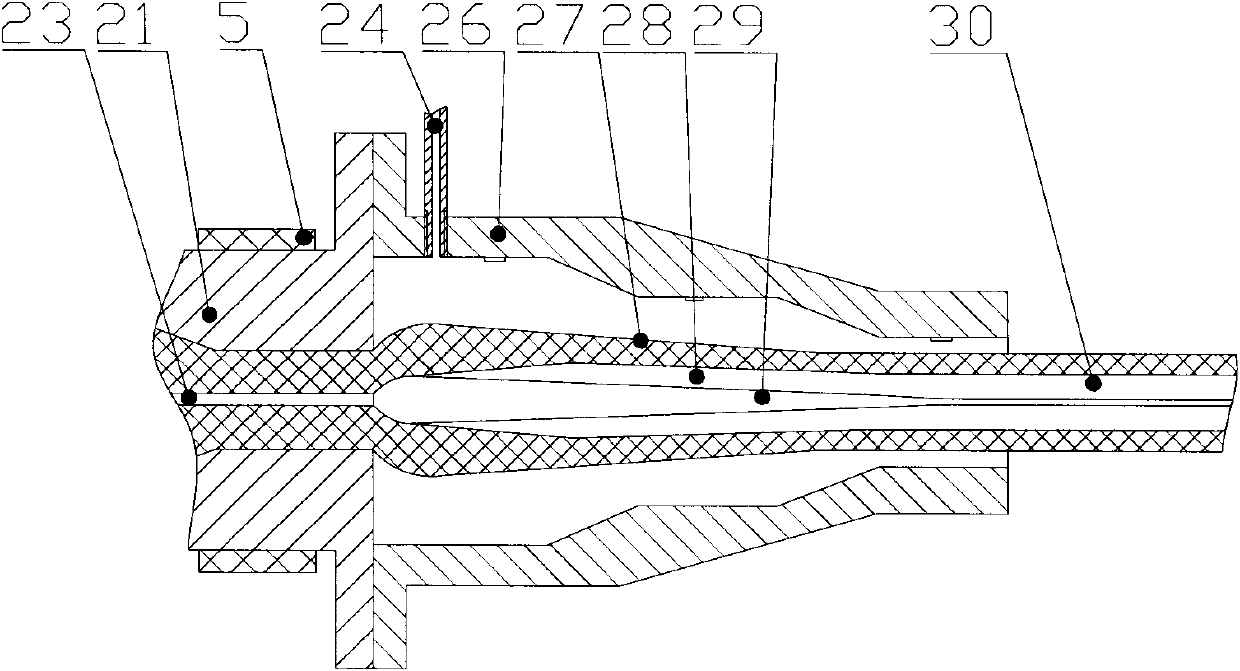

[0026] Principle of the present invention is: at first utilize selected plastics physical blowing agent (such as chlorofluorocarbon physical blowing agent, supercritical CO 2 etc.) can be dissolved in the plastic melt, the physical foaming agent inside the channel dissolves quickly under the internal pressure of the molding die, so that the incompletely formed channel gradually shrinks; secondly, using the dissolved physical foaming agent under pressure, temperature When changing rapidly, nucleation and precipitation of tiny cells will form a certain expansion, and the extrusion hollow channel will be further reduced, and finally the formation of microchannels will be realized. By controlling the flow rate and pressure of the injected physical foaming agent, the pressure field and temperature field in the molding die, and the flow rate of the cooling air flow at the exit of the shaping die, the required diameter of the microchannel in the plastic is adjusted.

[0027] The inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com