Method for repairing nano stick of zinc oxide in even diameter

A zinc oxide nanorod, uniform technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problem of difficulty in preparing zinc oxide nanorods, etc., and achieve the effects of easy operation, low reaction temperature and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The inventive method prepares the example of zinc oxide nanorod:

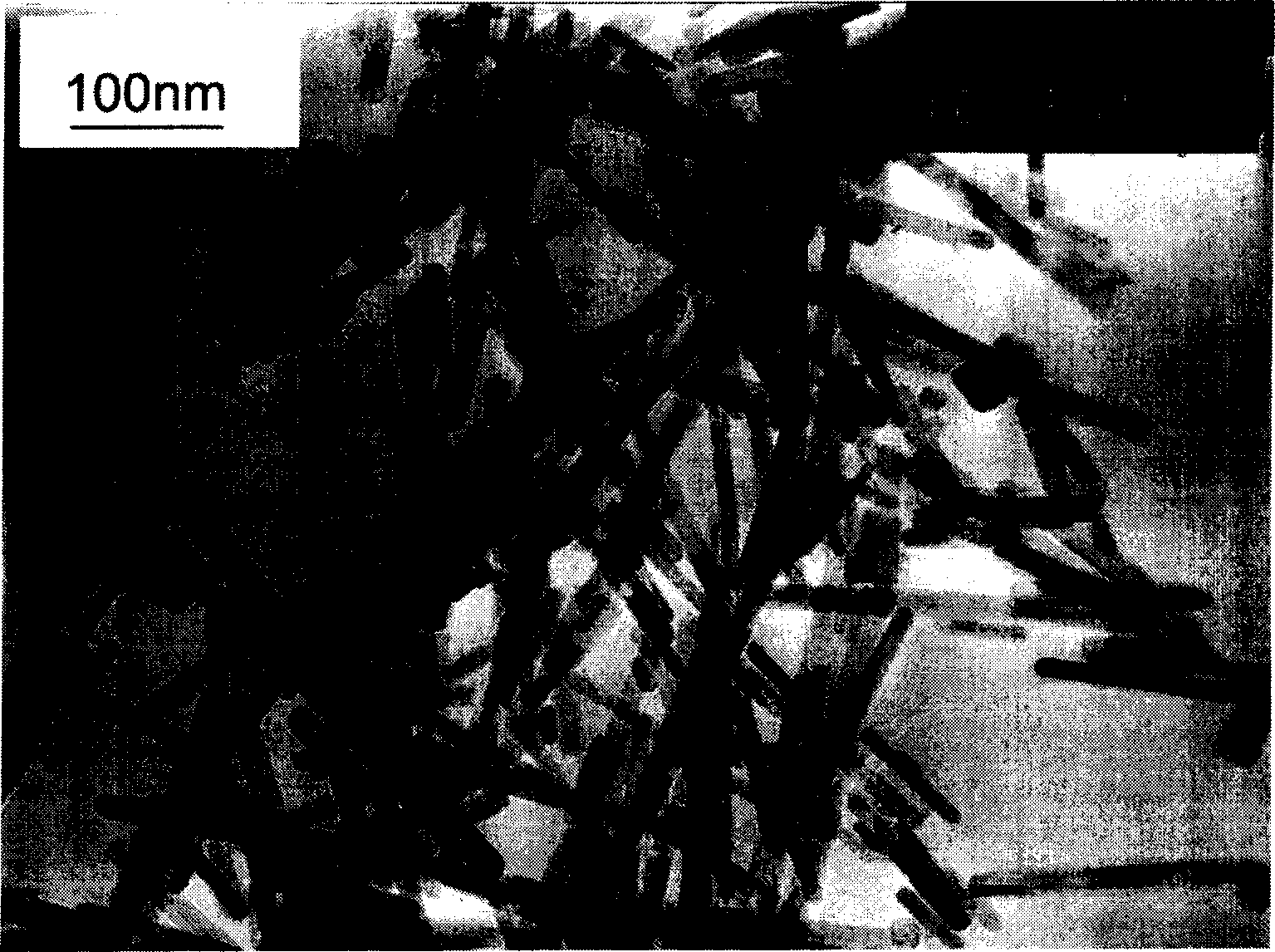

[0016] Dissolve zinc acetate in absolute ethanol, stir fully at 0°C to prepare a suspension with a concentration of 2%, and dissolve lithium hydroxide in absolute ethanol at room temperature to prepare a lithium hydroxide solution. The molar concentration Twice that of zinc acetate solution. An equal volume of lithium hydroxide solution was added dropwise to the stirred zinc acetate solution using a dropper, and the mixed solution was maintained at 0°C. Then the above mixed solution was sealed in a high-pressure reaction kettle, kept at 150°C for 10 hours, centrifuged to separate the reaction solution, fully washed with absolute ethanol, and dried to obtain zinc oxide nanorods with uniform diameters. The transmission electron microscope photo of the product See figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com