TiO2 nanowire array film light anode and preparation method thereof

A nanowire array and photoanode technology, applied in photosensitive equipment, photovoltaic power generation, semiconductor/solid-state device manufacturing, etc., can solve problems such as increased electron recombination rate, decreased diffusion coefficient, and limited battery conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

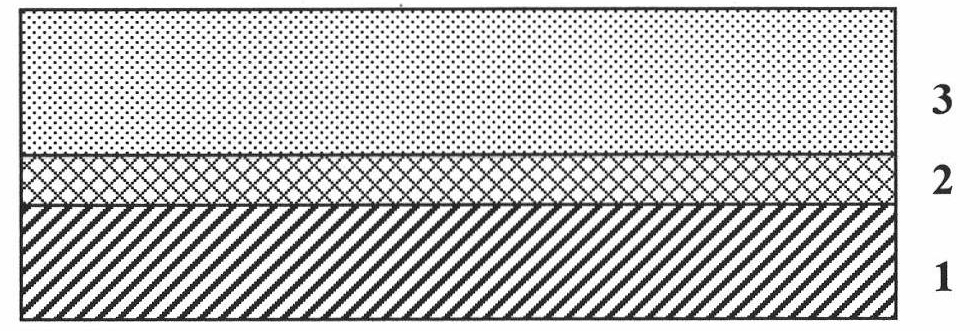

[0016] 1. Preparation of TiO on FTO glass substrate 2 Nanowire Array Films.

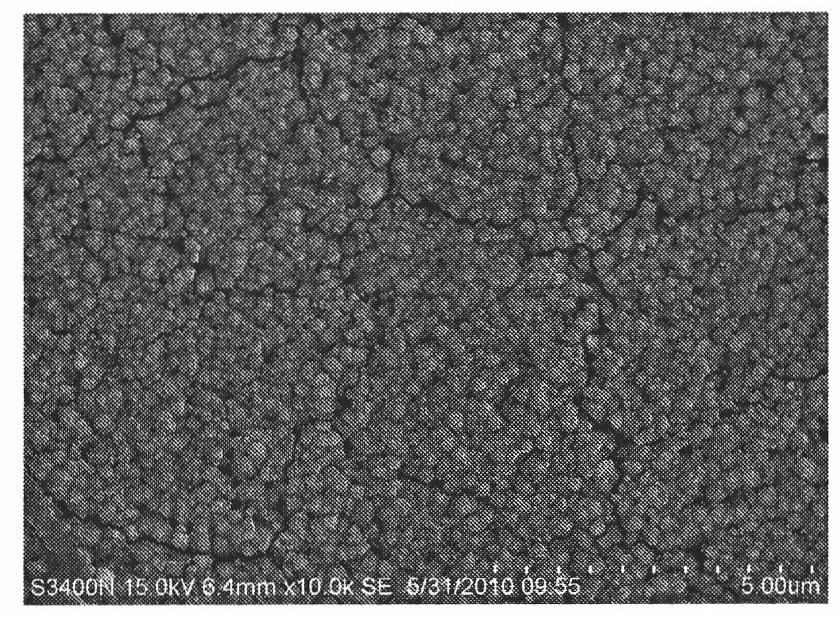

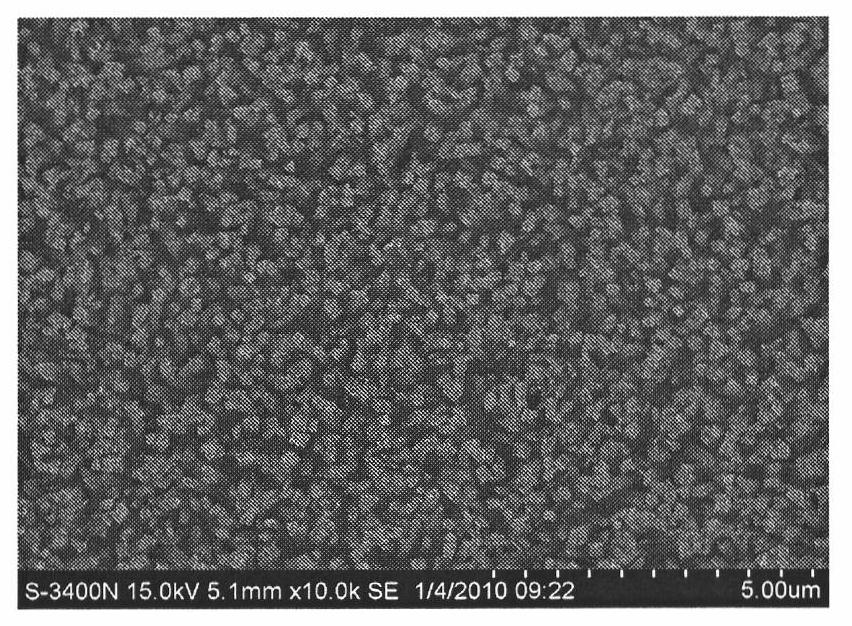

[0017] Preparation of TiO on FTO glass substrate by low temperature and low energy consumption hydrothermal synthesis technology 2 Nanowire Array Films. Under the condition of keeping the total volume at 40mL, concentrate hydrochloric acid and deionized water according to HCl:H 2 O=15:25, 20:20, 25:15, 26.7:13.3 volume ratio mixed, stirred with a magnetic stirrer for 5 minutes, then 0.4-0.8mL of butyl titanate was added dropwise, and stirred for 7 minutes. Put the prepared solution into a 100mL autoclave with a polytetrafluoroethylene liner, and place the cleaned FTO glass substrate with a width of 1.5cm and a length of 3.5-4cm in the reaction chamber with the conductive film facing downward. In the kettle, the angle between the glass and the wall is kept in the range of 10-45°, while keeping the FTO glass about 0.5 cm above the solution for connecting the test electrodes. Then seal the kettle, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com