Array nanotube, mfg. method and use thereof

A nanotube and array technology, applied in the field of array nanotubes, can solve the problems of complex pretreatment process, can not effectively improve electrical and mechanical properties, etc., and achieve excellent field emission performance, easy operation, and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

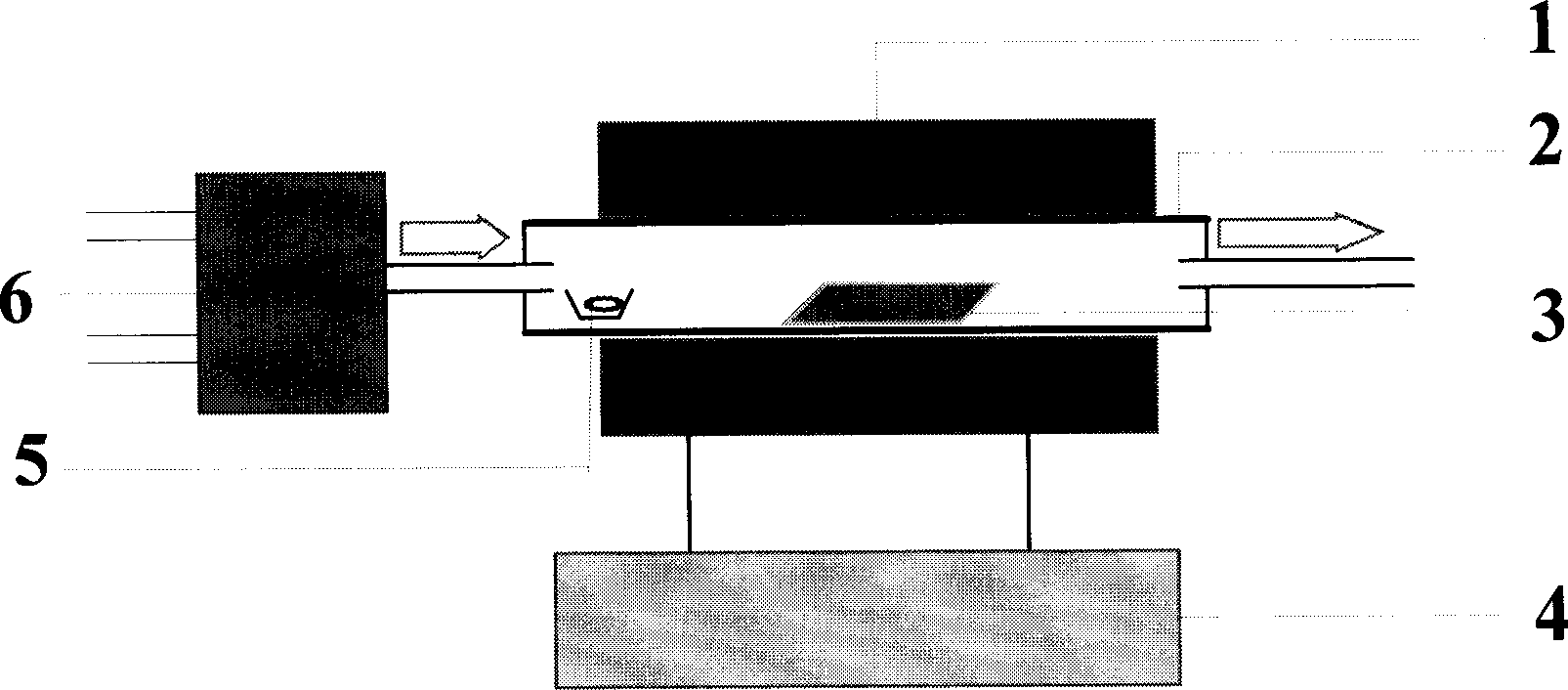

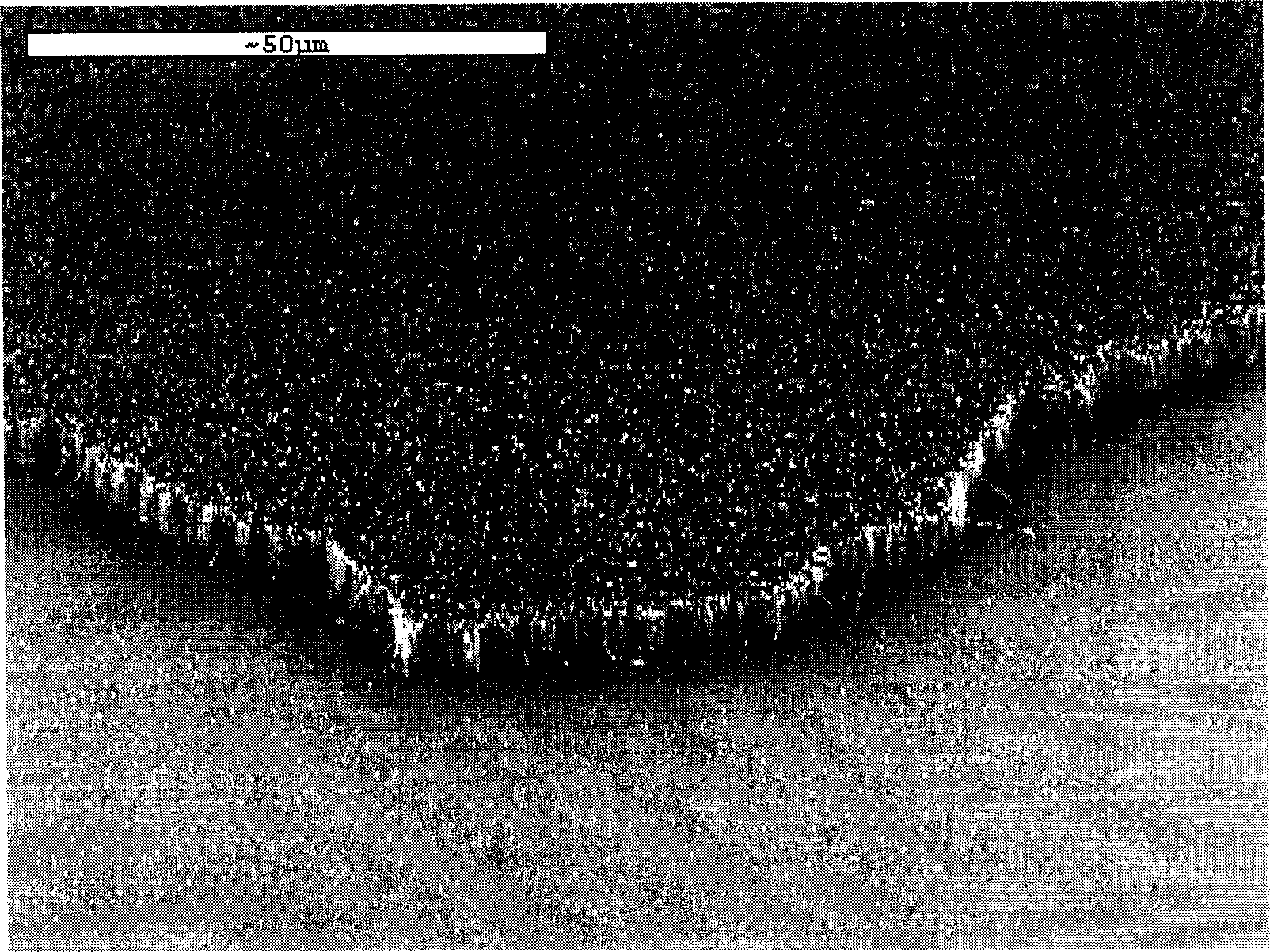

[0025] Example 1 as figure 1 The device (the tubular electric furnace is produced by Beijing Electric Furnace Factory, the model is SK 2 As shown in -4-13), put a 4×2 cm n-type monocrystalline silicon wafer into the middle of the quartz tube, connect the gas distribution system, feed ammonia gas at a flow rate of 40 ml per minute, and set the temperature at 900 ℃, the electric furnace is heated up, and when the furnace body center temperature reaches 900 ℃, a quartz boat (5 milliliters) filled with 0.5 gram of iron phthalocyanine is put into the area where the furnace mouth temperature is 550 ℃, and after constant temperature for 5 minutes, stop heating. Change the hydrogen gas of 20 milliliters per minute to bring the electric furnace to room temperature. Carbon nitride nanotubes with a diameter of 80 nanometers, a length of 9 micrometers, and a nitrogen content of 9% were prepared with regular arrays and uniform sizes. The length and purity of the nanotubes were determined...

Embodiment 2

[0026] Example 2 According to the preparation method of Example 1, except that the mass of iron phthalocyanine was increased from 0.5 g to 1 g, an array of carbon nitride nanotubes with a diameter of 120 nanometers, a length of 90 microns, and a nitrogen content of 9% was prepared.

Embodiment 3

[0027] Example 3 According to the preparation method of Example 1, except that the constant temperature time is increased from 5 minutes to 10 minutes, an array of carbon nitride nanotubes with a diameter of 100 nanometers, a length of 100 micrometers, and a nitrogen content of 9% is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com