Orientation bundling device, electrostatic spinning device and nanofiber yarn preparation method

A clustering device and nanofiber technology, applied in spinning machines, fiber processing, drafting equipment, etc., can solve the problems of difficult yarn control, continuous yarn formation, and batch preparation, etc., to achieve continuous and large-scale production The effect of production, quality improvement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

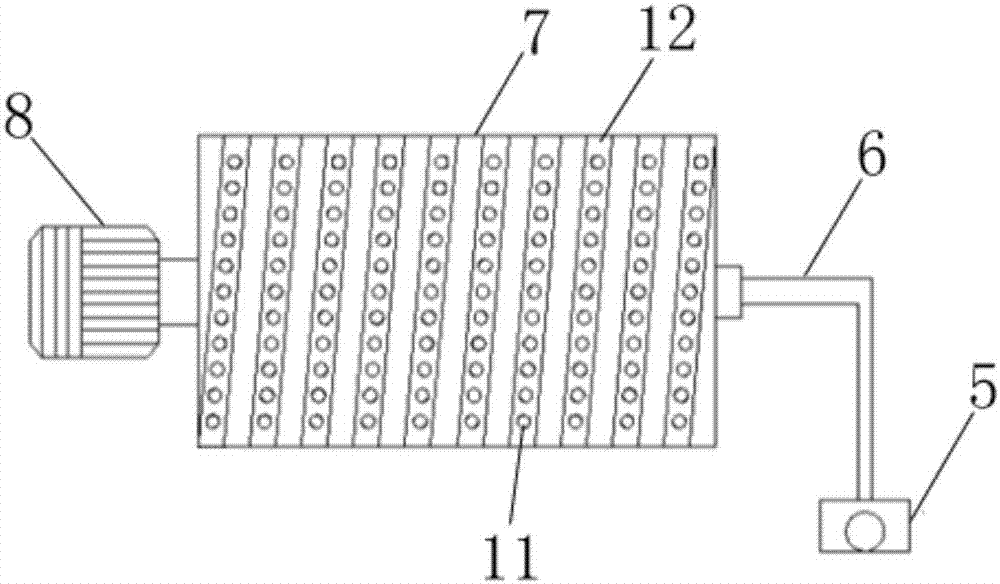

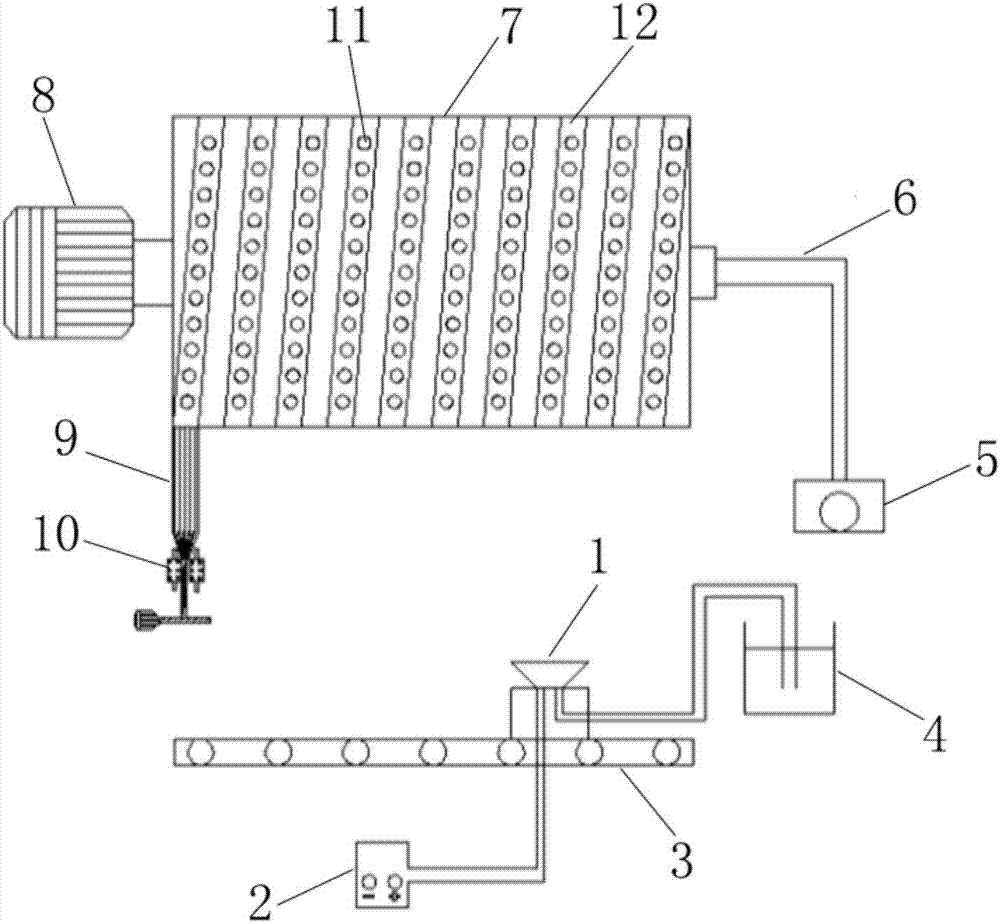

[0040] use as figure 2 In the electrospinning equipment shown, the spinneret 1 is a needleless nozzle. The solution is a solution prepared by polyacrylonitrile (PAN) and dimethylformamide (DMF) with a mass concentration of 10%, and the solution is injected into the spinneret 1 through the automatic liquid supply device 4 . Connect the spinneret 1 to the positive pole terminal of the high-voltage electrostatic generator 2, turn on the high-voltage electrostatic generator 2, and the jet will start to form at the spinneret 1, turn on the motor 8 to drive the negative-pressure fiber collection drum 7 to rotate, and the jet will be collected by the negative-pressure fiber The drum 7 receives, wherein the groove 12 on the peripheral surface of the negative pressure fiber collecting drum 7 is continuous in a circular spiral. Open the air extraction device 5 to extract air from the collection device, the air hole 11 of the collection device generates a negative pressure airflow, and...

Embodiment 2

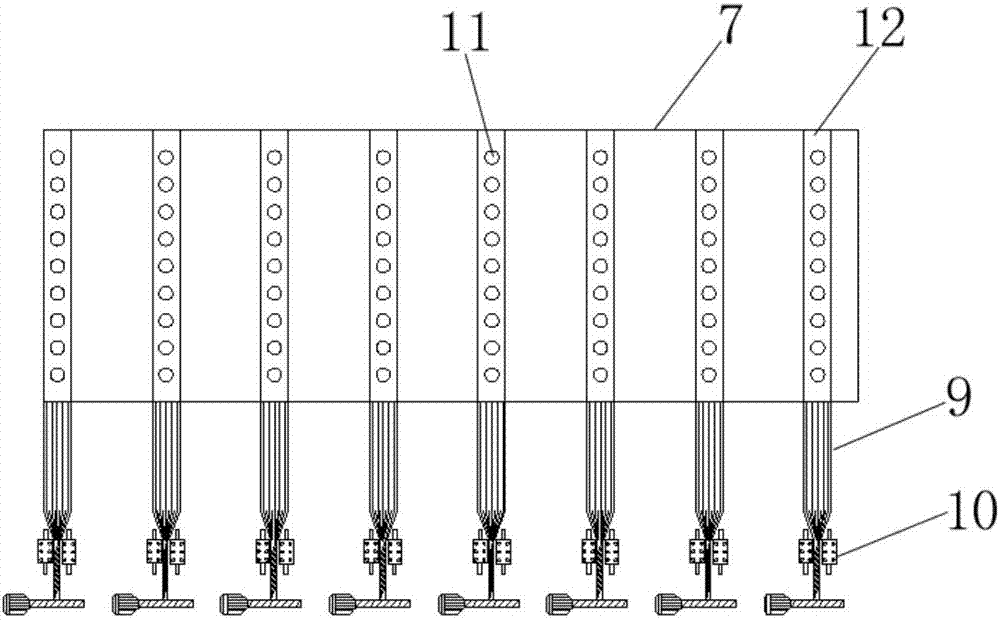

[0042] use as image 3 In the electrospinning equipment shown, the spinneret 1 is a needleless nozzle. The solution is a solution prepared by polyacrylonitrile (PAN) and dimethylformamide (DMF) with a mass concentration of 10%, and the solution is injected into the spinneret 1 through the automatic liquid supply device 4 . Connect the spinneret 1 to the positive pole terminal of the high-voltage electrostatic generator 2, turn on the high-voltage electrostatic generator 2, and the jet will start to form at the spinneret 1, turn on the motor 8 to drive the negative-pressure fiber collection drum 7 to rotate, and the jet will be negative-pressured The drum collecting device receives, wherein the grooves 12 on the peripheral surface of the negative pressure drum collecting device are arranged in parallel along the drum circumference. Open the air extraction device 5 to extract air from the collection device, and the air holes 11 of the collection device generate a negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com