Differential gear with high bearing capacity

A high load-carrying capacity differential technology, applied in the direction of differential transmission, transmission box, belt/chain/gear, etc., can solve the problems of weakening the strength of other parts, failing to achieve the best design of parts, and failing to achieve , to achieve the effects of reduced wall thickness, high load-bearing capacity, and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with accompanying drawing:

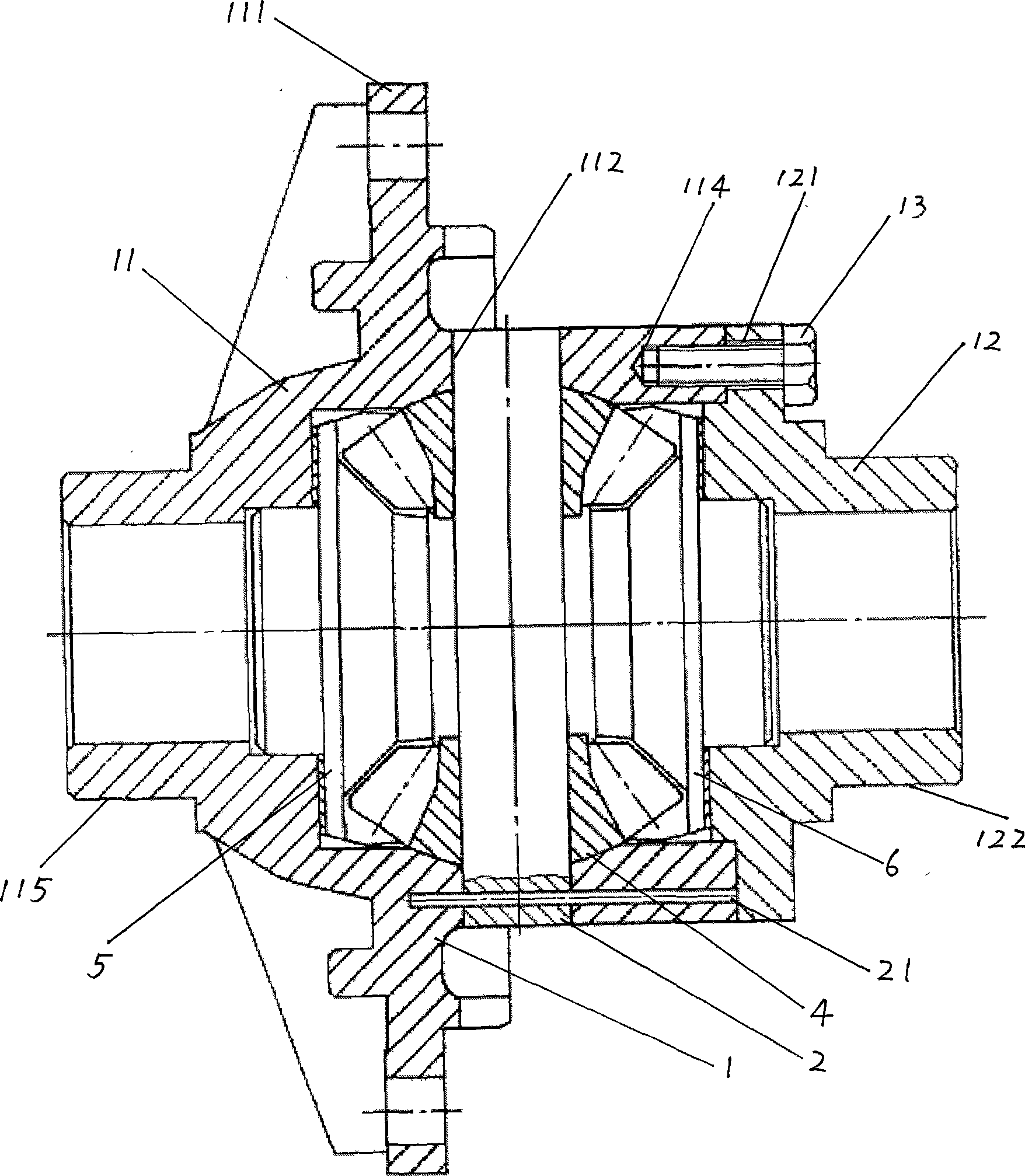

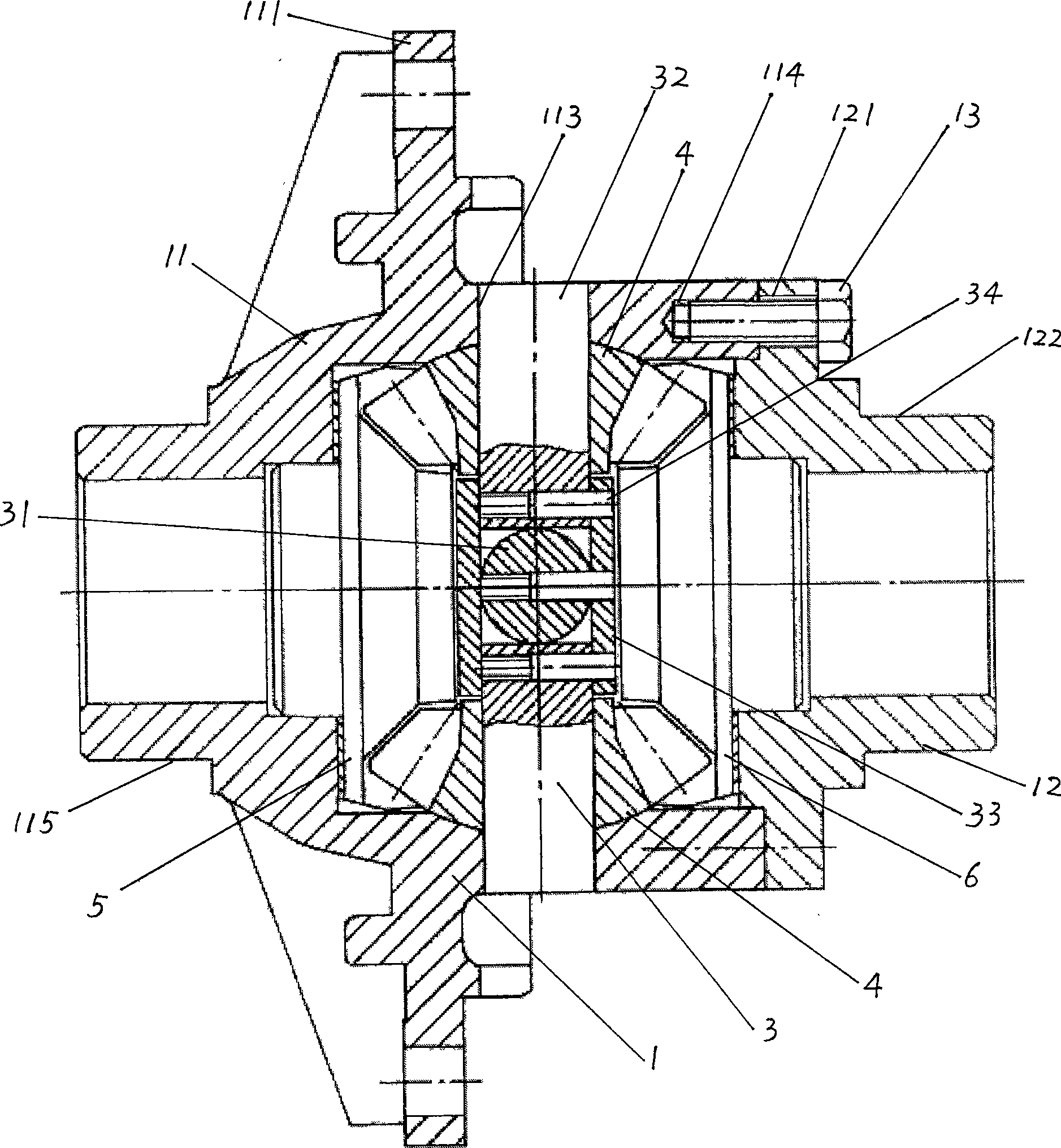

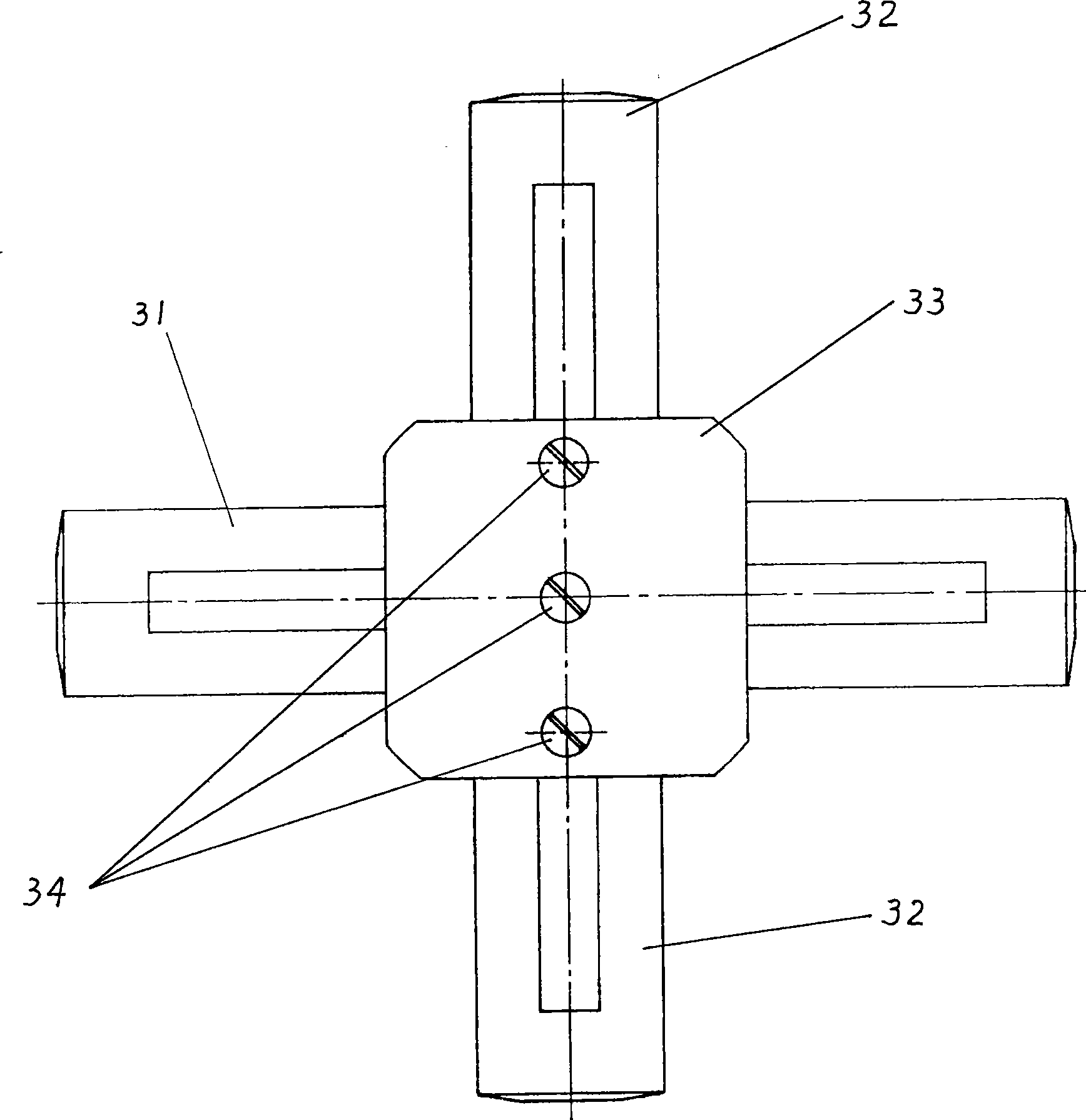

[0033] Such as Figure 1-12 As shown, the present invention is applicable to a high load capacity differential between driving wheels, which includes a differential case 1 and is fixed in the differential case 1 and transmits input torque to the planetary gear 4 and maintains its position The straight shaft 2 or combined cross shaft 3, the left side shaft gear 5 and the right side side gear 6 meshed with the planetary gear 4;

[0034] The differential case 1 is composed of a left half case 11 and a right half case 12 through connecting screws 13 . Among them, the left half shell 11 has a flange plate 111 for installing the driven gear of the final drive, a pin hole 112 for setting a straight shaft or a pin hole 113 for setting a cross shaft, and a bolt for setting the connecting bolt 13 Holes 114 and shaft diameters 115 for mounting bearings. The right half shell 12 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com