Mold and method for preparing hard alloy hollow sphere

A hollow sphere and cemented carbide technology, which is applied in the field of preparation of hollow sphere parts in cemented carbide materials, can solve the problems of high scrap rate, long dewaxing time, large consumption of raw materials, etc., and improve the compressive and impact strength , enhanced area and connection strength, and obvious social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with specific drawings and specific embodiments.

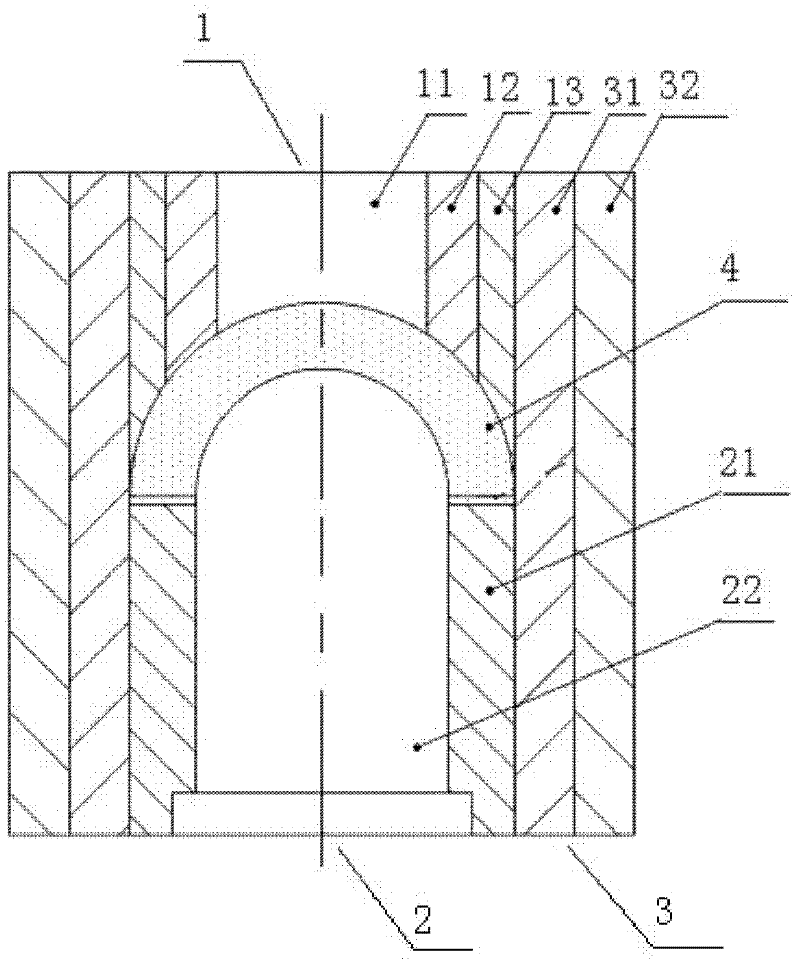

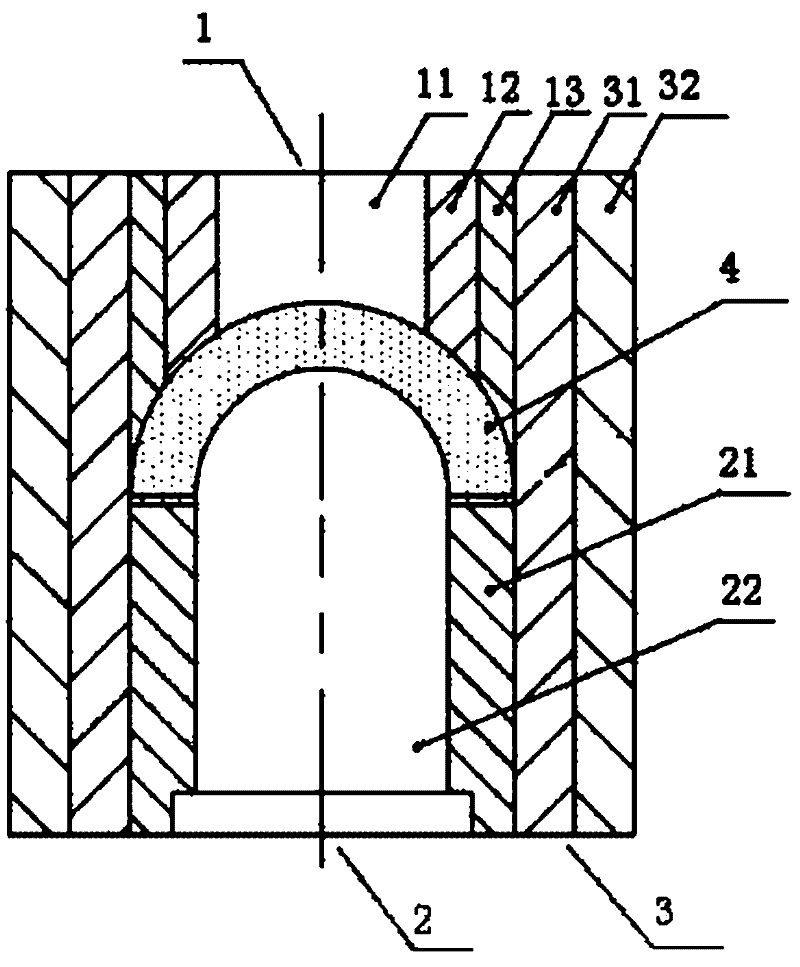

[0041] Such as figure 1 Shown, a kind of mold of the present invention prepares cemented carbide hollow sphere, this mold is made up of upper mold 1, lower mold 2 and the overcoat 3 that is used to fix described upper mold 1 and lower mold 2;

[0042] Wherein, the upper mold 1 is a spherical crown-shaped combined upper punch, which is used for the internal molding of the hemispherical billet; the spherical crown-shaped combined upper punch adopts a concentric circular sleeve structure, and the upper punch is sequentially arranged from the inside to the outside. Head Ⅰ11, upper punch Ⅱ12 and upper punch Ⅲ13;

[0043] The lower mold 2 is composed of a toothed pressure ring 21 and a hemispherical mandrel 22, the toothed pressure ring 21 is sleeved on the outside of the hemispherical mandrel 22; the upper end surface of the toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com