Method for preparing pitch-based hollow carbon spheres

A pitch-based, carbon ball technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as difficulty in large-scale production, and achieve the effects of simple preparation, large output and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of silica balls

[0022] At 25 o At C, mix 100 ml of absolute ethanol, 6 ml of concentrated ammonia (25%) and 2 ml of deionized water, add 3 ml of ethyl orthosilicate under stirring, stir at room temperature for 6 hours, then centrifuge, Washing in the oven 90 o C Dry for use.

[0023] 2. Preparation of core-shell silica spheres

[0024] Disperse the above 200 mg silica spheres in 60 ml deionized water, sonicate it for 1 h, and wait until it is completely dispersed to obtain a white emulsion, add 200 mg cetyltrimethylammonium bromide to it, stir for 30 min, and then Add 25 ml of absolute ethanol and 0.9 ml of concentrated ammonia and stir for 10 min, and finally add 0.6 ml of ethyl orthosilicate and stir for 6 h. The white emulsion is filtered, washed, and dried at 90 °C for use.

[0025] 3. Preparation of hollow carbon balls

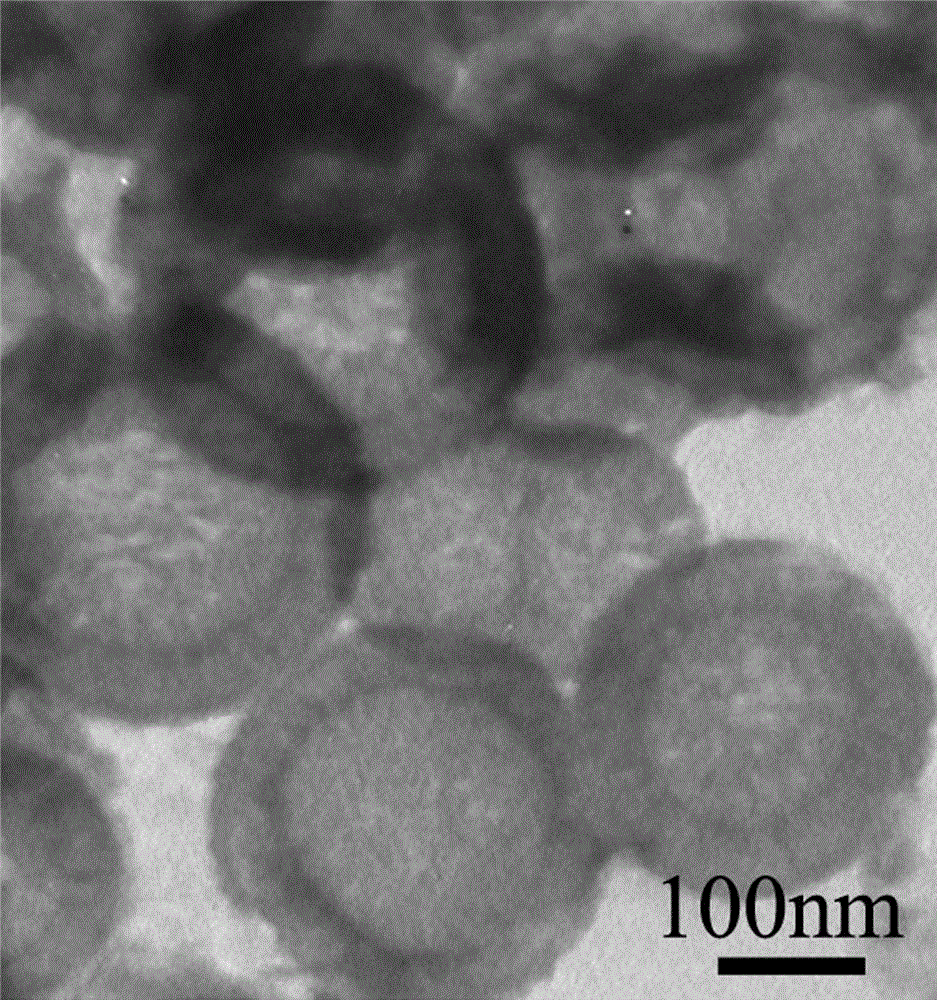

[0026] The hollow carbon spheres were prepared by vapor deposition method. Two corundum porcelain boats containing 10 g pitch and 1 g te...

Embodiment 2

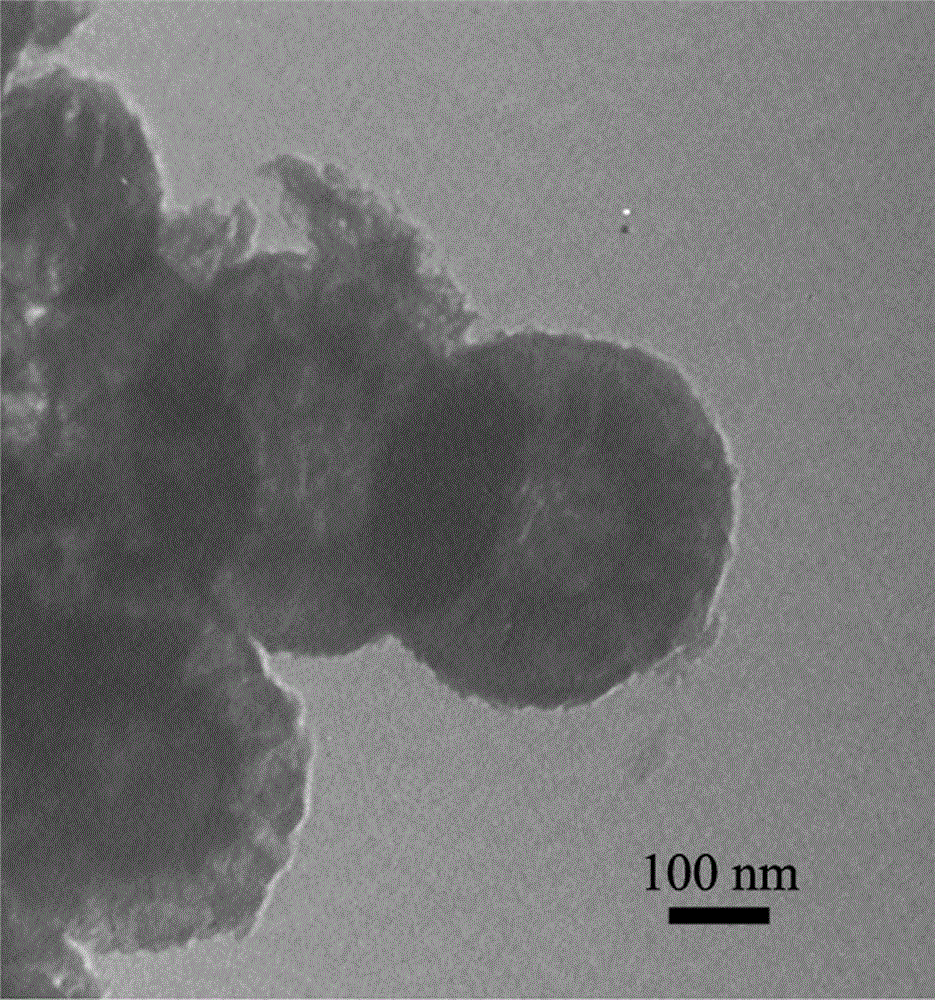

[0028] The difference between Example 2 and Example 1 is that when preparing silica spheres with a core-shell structure, the amount of cetyltrimethylammonium bromide added has been increased from 200 mg to 400 mg. The amount of ethyl acid added was increased from 0.6 ml to 1.5 ml, and the other preparation process was the same as in Example 1. figure 2 The TEM image of hollow carbon spheres prepared in Example 2. From figure 2 It can be seen that by changing the addition amount of cetyltrimethylammonium bromide and ethyl orthosilicate, the wall thickness of the obtained hollow carbon spheres changed from 50 nm in Example 1 to 110 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com