Investment casting method capable of controlling wall thickness of aero-engine hollow blade

An aero-engine and hollow blade technology, which is applied in the field of precision casting, can solve problems such as being difficult to eliminate, form gaps, and difficult to handle, and achieve the effect of facilitating repairs and avoiding the formation of gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

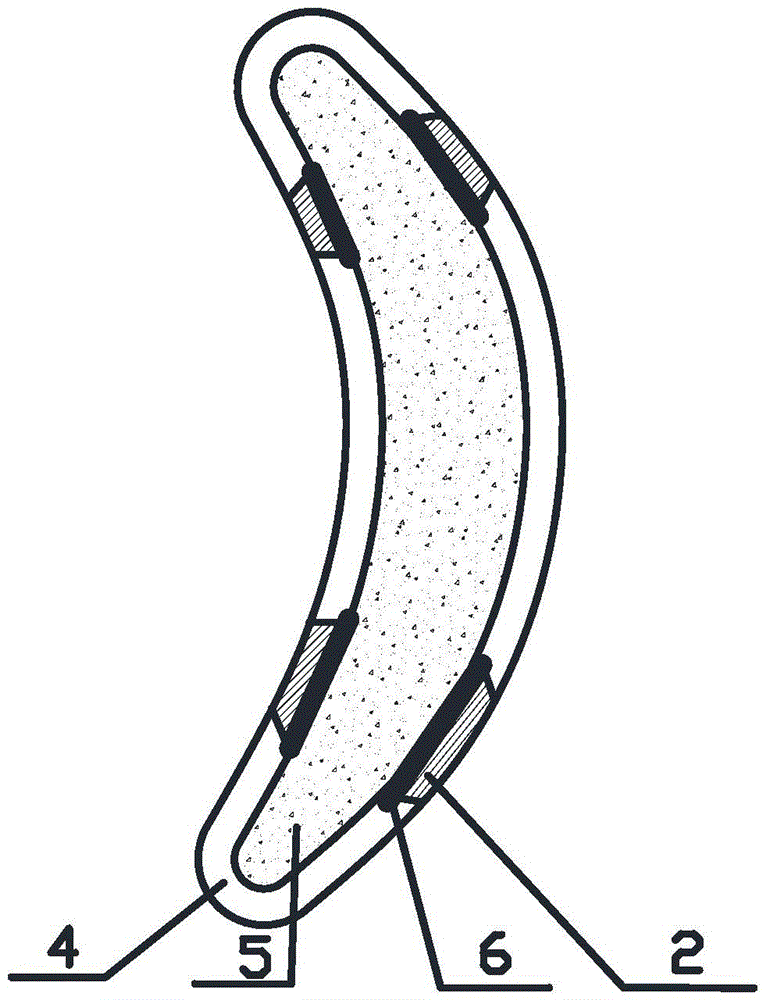

[0025] This embodiment uses the investment casting method of the present invention to cast a certain type of engine quadruple hollow blade. The wall thickness of the blade body is required to be 1.0-1.5mm. If the traditional plastic core support and the free end of the cylinder are used, problems such as deflection, leakage, and broken core are extremely prone to occur. At the same time, the bumps formed by the plastic core support are difficult to eliminate and damage the surface of the casting. Casting the blade with the traditional method, the scrap rate due to deflection, leakage and broken core can reach up to 50%.

[0026] Adopt the method of the present invention to cast this blade, its specific operation steps are as follows:

[0027] Step 1: Press the core support

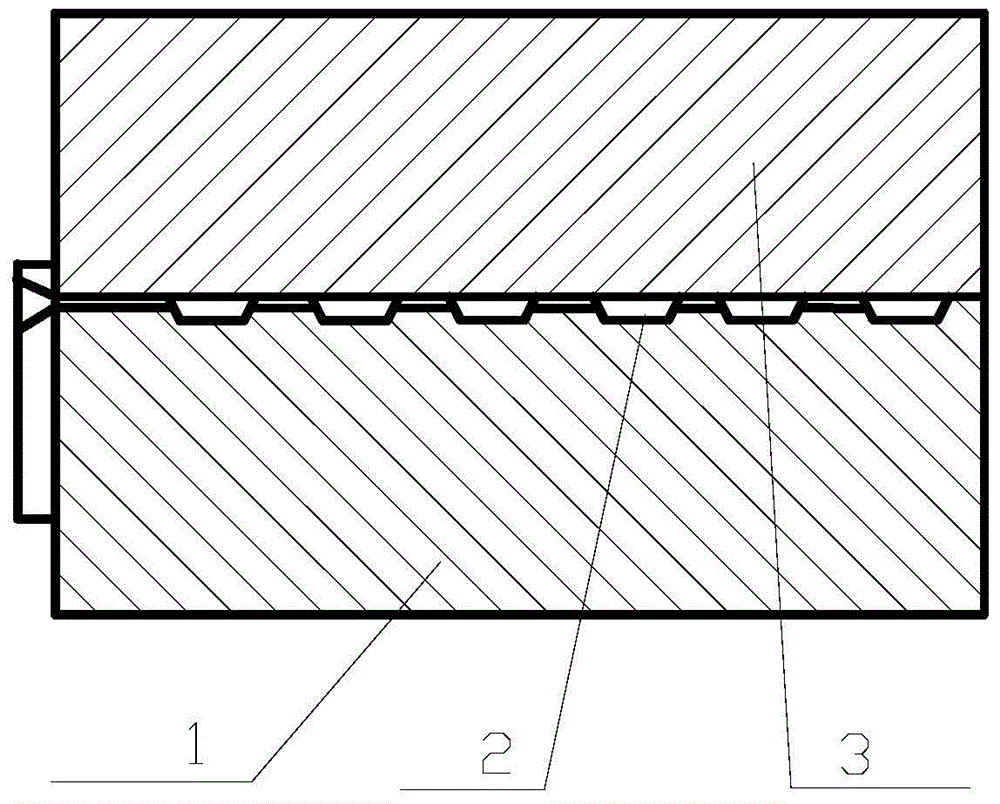

[0028] combine figure 1 , the shape of the core support 2 is a circular truncated shape, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com