A rotary electric shaver shaving head device

An electric shaver, rotary technology, applied in the direction of metal processing, etc., can solve the problems of reducing the service life of the shaver head, unfavorable energy saving and environmental protection, and easy wear of the cutting edge, so as to improve the shaving efficiency and improve the shaving effect , Enhance the effect of matrix strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with specific embodiments.

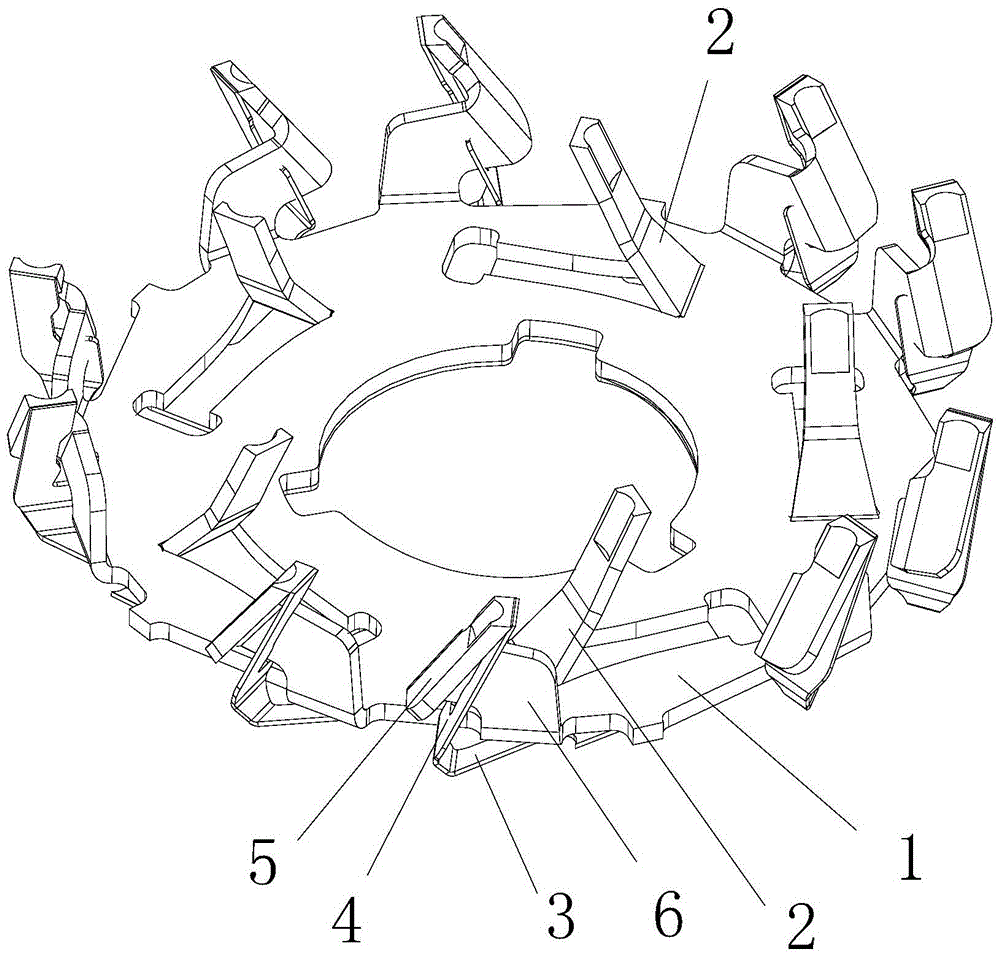

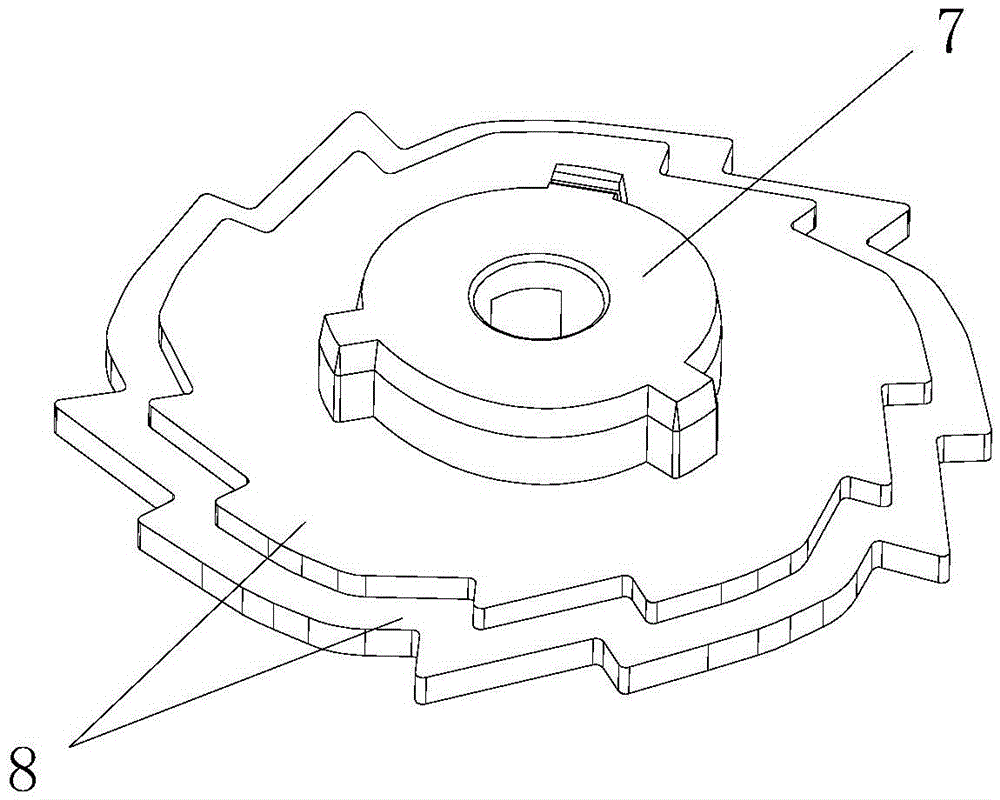

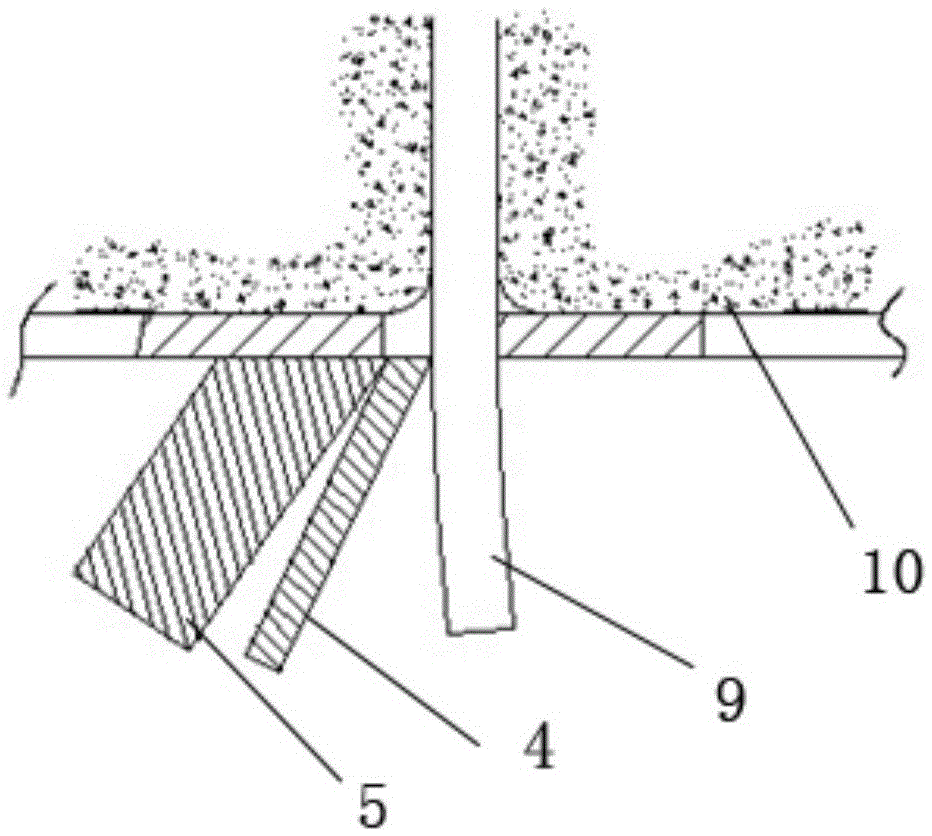

[0027] Such as Figure 1-2 A rotary electric razor blade shown as shown includes a main blade base 1. Two sets of coaxial inner ring cutters 2 and outer ring cutters 5 are arranged on the main blade base 1. The main blade base An auxiliary blade is arranged at the bottom of 1 and an elastic auxiliary cutter 4 is arranged on the periphery of the auxiliary blade; the auxiliary cutter 4 is arranged at the front end of the working part when the outer ring cutter 5 rotates, and the auxiliary cutter 4 forms an angle with the outer ring cutter 5 of the main blade. The lower part of the auxiliary cutter 4 is integrally connected with the negative film 3, the negative film 3 is arranged obliquely downward, and the auxiliary cutter 4 is arranged obliquely relative to the outer ring cutter 5. The outer ring cutter 5 and the main blade base 1 are connected by a bending arm 6, a bayonet is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com