Reciprocating type tool bit set

A cutter head group, reciprocating technology, applied in metal processing and other directions, can solve the problems of poor support of the outer cutter net, easy to break, inability to shave clean body hair, high manufacturing and assembly costs, and improve cutting stability and structure. Compact, long-standing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

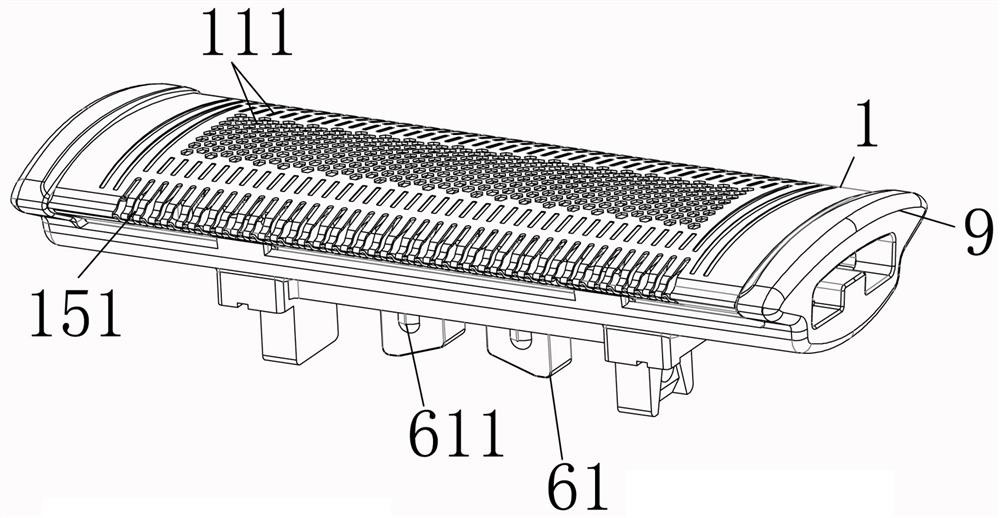

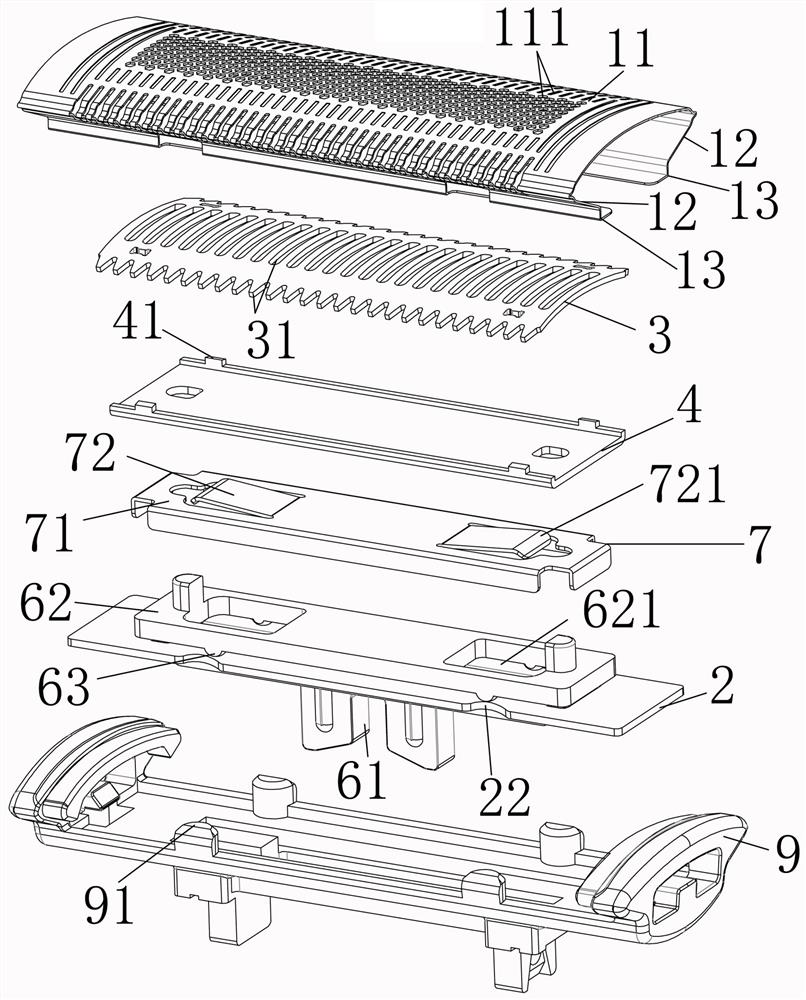

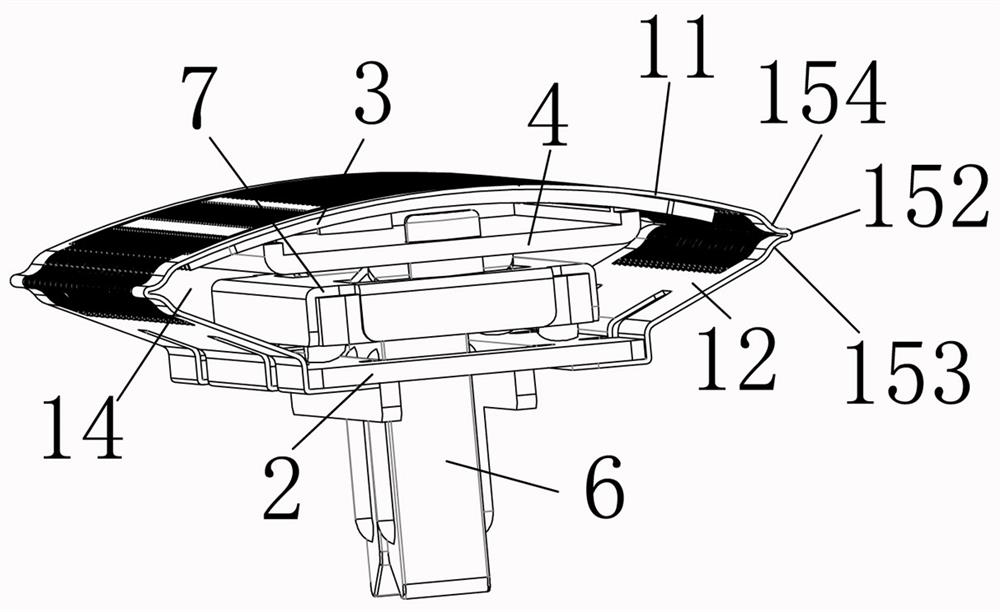

[0024] like figure 1 , figure 2 , image 3 , Figure 4 As shown, an embodiment of the reciprocating cutter head group of the present invention includes a housing 9, an arc-shaped fixed blade 1, a cutting movable knife 3 that is adapted to the fixed movable knife and has a cutting edge, and a The movable knife rest 4, the elastic body 7 arranged under the movable knife rest, the reciprocating transmission part 6, the holding plate 2 made of rigid material, the fixed blade 1 is as thin as 10 filaments or even as thin as 4-5 filaments The flexible metal sheet is integrally formed.

[0025] The fixed blade 1 includes a skin-friendly wall 11 that is used as a skin-facing wall and has a plurality of first hair inlets 111 during operation, two retracted walls 12 that respectively form retracted angles with both sides of the skin-friendly wall, and The two connecting parts 13 and the two retracting walls 12 are respectively connected with the arcs of the two retracting walls and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com