Tracking and Sweeping Algorithm for Dresser Motor in Chemical Mechanical Planarization

A technology of chemical mechanics and scanning algorithm, which is applied in the field of tracking and scanning algorithm, can solve problems such as poor smoothness, cumulative error of trimmer operating cycle time, poor fitting degree of preset operating curve, etc., to achieve smoothness improvement and improved fitting degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

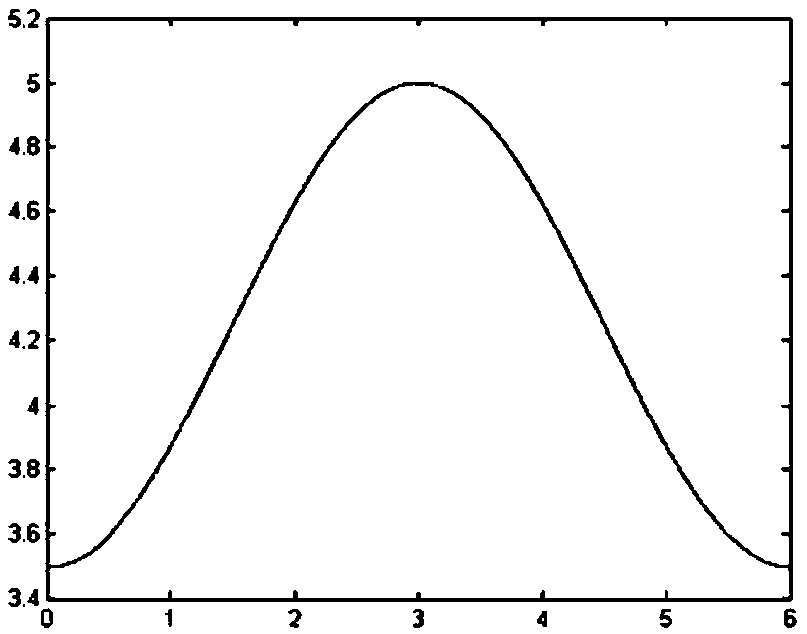

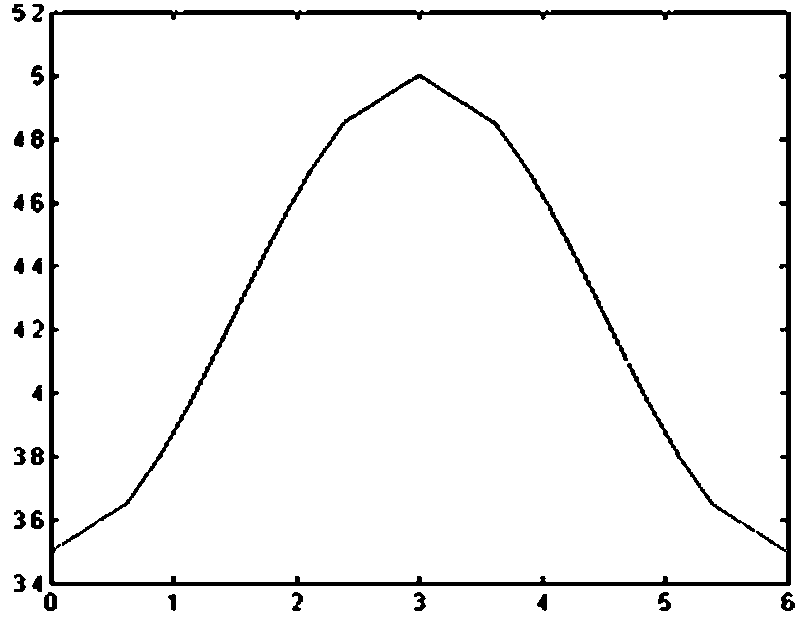

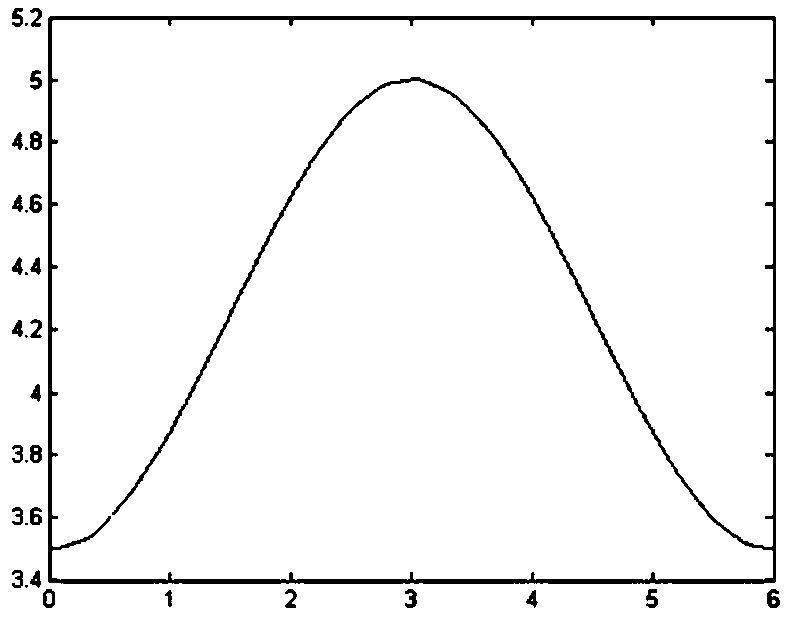

[0057] The starting point is 3.5 inches, the ending point is 5 inches, the frequency is 10 Hz, and the displacement interval Zone is 10 (the preset threshold value). Now when the standard sin curve is selected, the default curve ( figure 1 ), the fitting curve of the prior art scheme ( figure 2 ) and the present invention ( image 3 ) for comparison.

[0058] image 3 The motor operates according to the algorithm provided by the present invention, and a time period is equally divided into 20 sections. Taking the motor operating parameters in the first subsection as an example, the time of each subsection of the motor operation is set to 150ms:

[0059] (1) The starting point of the first segment is 0, the cubic curve of the first segment is A[0]=0.149, B[0]=0.306, C[0]=0, D[0]=3.5,

[0060] Therefore, the initial displacement Y[0] and the final displacement Y[1] of the first subsection are respectively:

[0061] Y[0]=3.5mm

[0062] Y[1]=A[0]×(0.15-0) 3 +B[0]×(0.15-0) ...

Embodiment 2

[0070] The starting point is 3.5 inches, the ending point is 5 inches, the frequency is 10 Hz, the displacement interval Zone is 10 (the preset threshold), and the time interval ratio of the fifth displacement interval is changed to 5, and the preset curve ( Figure 4 ), the fitting curve of the prior art scheme ( Figure 5 ) and the fitting curve of the present invention ( Figure 6 )Compare.

[0071] Figure 6 The motor operates according to the algorithm provided by the present invention, and a time cycle is divided into 20 segments. Taking the motor operating parameters in the first small segment as an example, the time for each segment of the motor to run is set to 150ms

[0072] (1) The starting point of the sixth segment is 0, the cubic curve of the sixth segment A[6]=-1.280, B[6]=0.960, C[6]=0.548, D[6]=3.65,

[0073] Therefore, the initial displacement Y[0] and the final displacement Y[1] of the first subsection are respectively:

[0074] Y[0]=A[6]×(0.75-0.489) 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com