Silver nano-disc, its preparation method, and gold nano-ring and assembly prepared by using the same

A silver nano-wafer technology, applied in the field of nano-materials, can solve the problems of unfavorable product promotion, low product quality, uneven ring shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

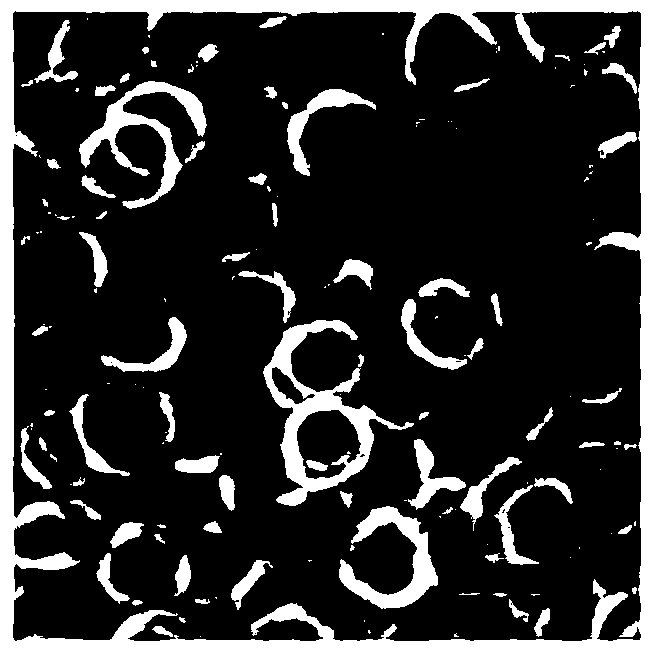

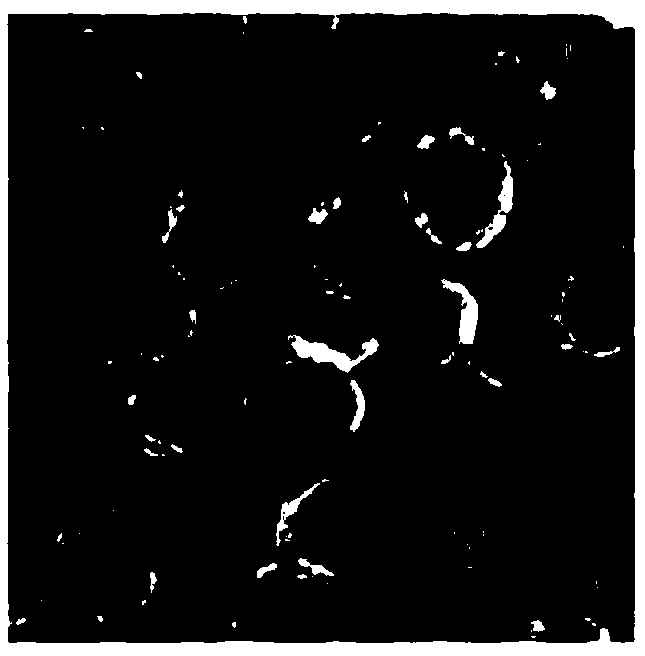

Image

Examples

Embodiment 1

[0126] (1) Synthesis of silver nanodiscs and gold nanorings

[0127] (a) Synthesis of silver seeds

[0128] Mix 200mL ultrapure water, 100μL, 0.05M silver nitrate, 12mL, 100mM sodium citrate, and 240μL hydrogen peroxide in a 500mL beaker, then add freshly prepared 2.4mL, 0.05M sodium borohydride. The solution was stirred slowly for 5 min, and then incubated at 4°C for 2 h in the dark. The synthesized silver seeds were centrifuged at 14000 revolutions per minute (rpm) for 10 min, and the precipitate was collected for subsequent synthesis of silver nanodiscs.

[0129] (b) Synthesis of silver nanodiscs

[0130]Add 22 mL of ultrapure water, 10 mL of acetonitrile, 100 μL of 0.05M ascorbic acid, 100 μL of 0.05M sodium citrate into a 100 mL beaker, and stir vigorously. Add the silver seeds synthesized by the above method, and 120 μL, 0.1M silver nitrate. The mixed solution was vigorously stirred for 30 min, and the obtained silver nanodiscs were centrifuged at 12000 rpm for 20 mi...

Embodiment 2

[0141] (1) Synthesis of silver nanodiscs and gold nanorings

[0142] (a) Synthesis of silver seeds

[0143] Mix ultrapure water (400mL), silver nitrate (300μL, 1M), sodium citrate (24mL, 100mM), hydrogen peroxide (2mL) in a 1000mL beaker, and then add freshly prepared sodium borohydride (0.6mL, 2M) . The solution was stirred slowly for 10 min, and then incubated at 4° C. for 3 h in the dark. The synthesized silver seeds were centrifuged at 12000 rpm for 20 min, and the precipitate was collected for subsequent synthesis of silver nanodiscs.

[0144] (b) Synthesis of silver nanodiscs

[0145] Add 22 mL of ultrapure water, 10 mL of acetonitrile, 150 μL of 0.1M ascorbic acid, 100 μL of 0.05M sodium citrate into a 100 mL beaker, and stir vigorously. Add the silver seeds synthesized by the above method, and 120 μL, 0.1M silver nitrate. The mixed solution was vigorously stirred for 30 min, and the obtained silver nanodiscs were centrifuged at 10,000 rpm for 30 min, and dissolved...

Embodiment 3

[0164] (1) Synthesis of silver nanodiscs and gold nanorings

[0165] (a) Synthesis of silver seeds

[0166]Mix ultrapure water (400mL), silver nitrate (300μL, 0.1M), sodium citrate (12mL, 75mM), hydrogen peroxide (480μL) in a 500mL beaker, and then add freshly prepared sodium borohydride (1.2mL, 0.5 M). The solution was stirred slowly for 10 min, and then incubated at 4° C. for 3 h in the dark. The synthesized silver seeds were centrifuged at 12000 revolutions per minute (rpm) for 30 min, and the precipitate was collected for subsequent synthesis of silver nanodiscs.

[0167] (b) Synthesis of silver nanodiscs

[0168] Add 88mL ultrapure water, 20mL acetonitrile, 600μL, 0.1M ascorbic acid into a 200mL beaker, and stir vigorously. Add the silver seeds synthesized by the above method, and 480 μL, 0.1M silver nitrate. The mixed solution was vigorously stirred for 30 min, and the obtained silver nanodiscs were centrifuged at 12000 rpm for 20 min, and dissolved in 24 mL of 1 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com