Collapse-free sound film

A sound film and polyester film technology, applied in the field of non-collapsing sound film, can solve the problems that the basic shape of the pattern is easy to collapse, collapse, and cannot be restored, so as to reduce the variation of acoustic characteristics, improve product reliability, and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

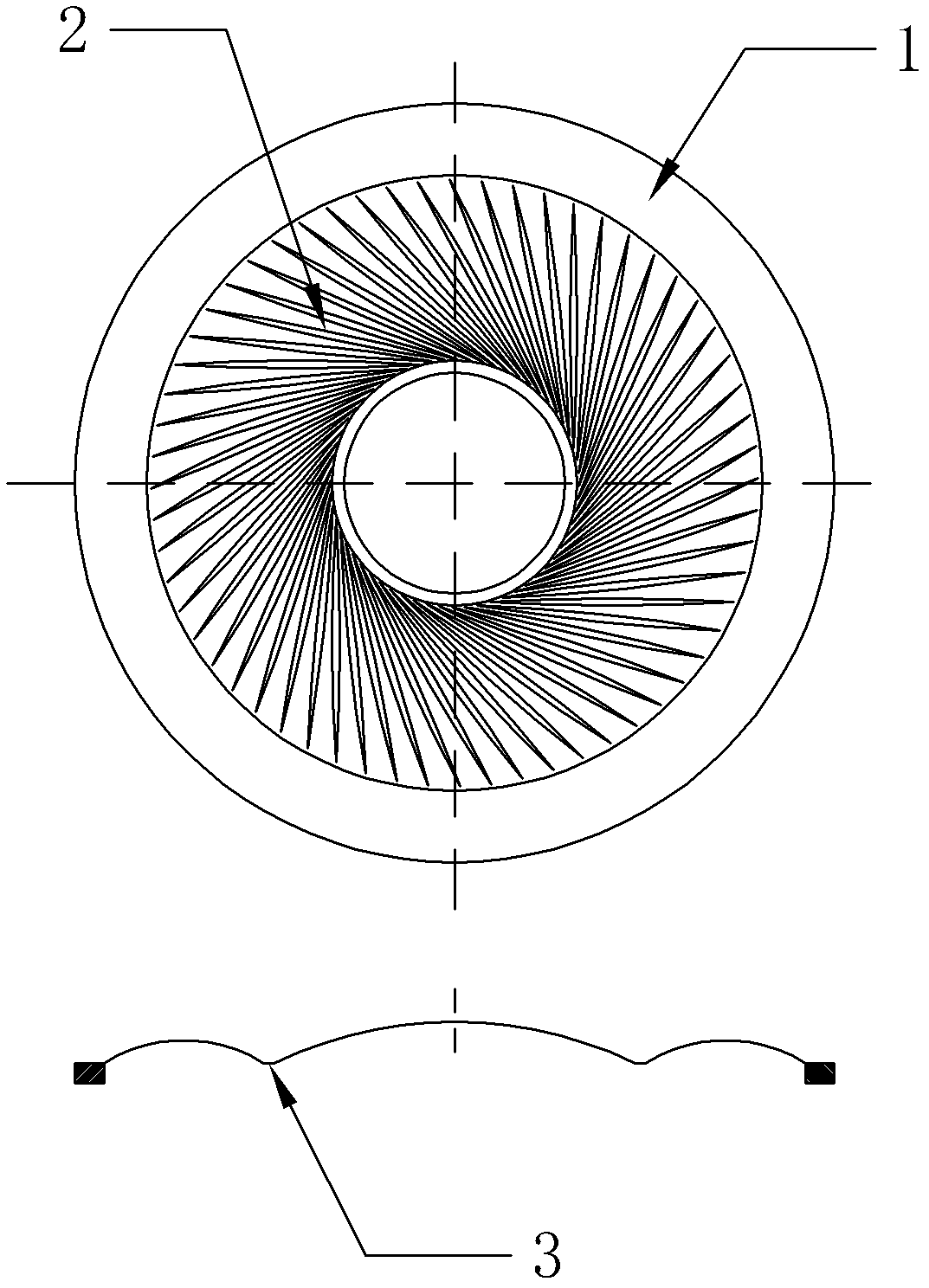

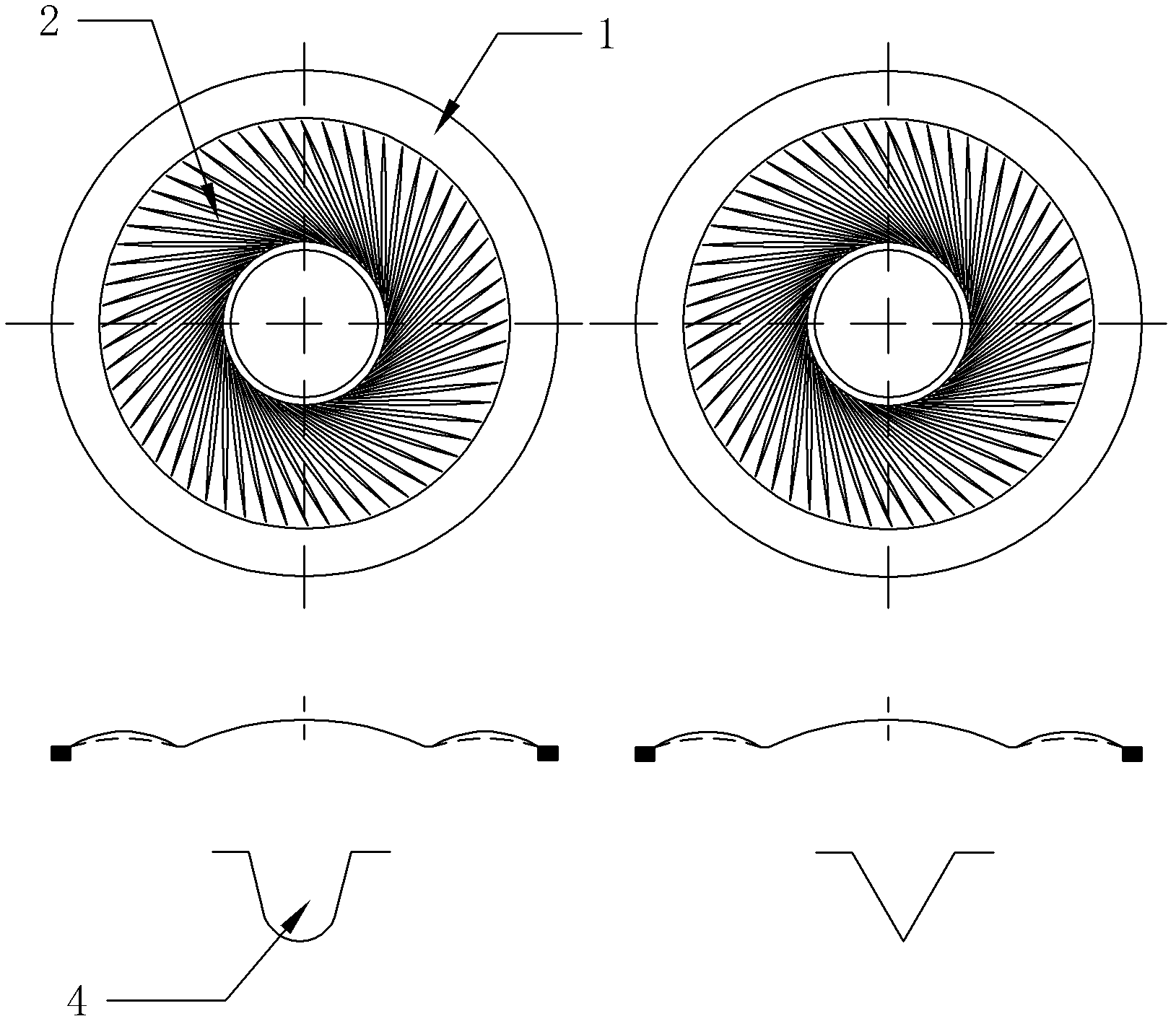

[0018] A kind of non-collapsing sound membrane of present embodiment, as figure 1 , 2 As shown, there is an edge arc 1 around the sound film, and a pattern 2 is arranged on the edge arc 1. The cross section of the edge arc 1 is formed by connecting one or more arcs, and the connection between the arc and the arc is a rounded smooth connection 3 ;The cross section of the pattern 2 is U-shaped 4, the width of the pattern 2 is twice the depth, the trend of the pattern 2 is basically the same as the edge arc, and the R value is larger, that is, the arc flower; the sound film is made of polyester film, and the computer 3D is used Drawing, according to the customer's electro-acoustic parameter requirements, reasonably design the edge arc and pattern, for the thickness of the raw material polyester film is less than 16 microns, use the edge plus copper ring design, for different materials and thicknesses, adopt a reasonable molding process, the edge plus copper ring To use air pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com