Mold release film for production of ceramic green sheet

A technology for ceramic green sheets and mold release films, used in manufacturing tools, ceramic molding machines, coatings, etc., can solve the problem of inability to disappear thick protrusions, and achieve the effect of not heavy peeling force, excellent processability, and pinhole reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

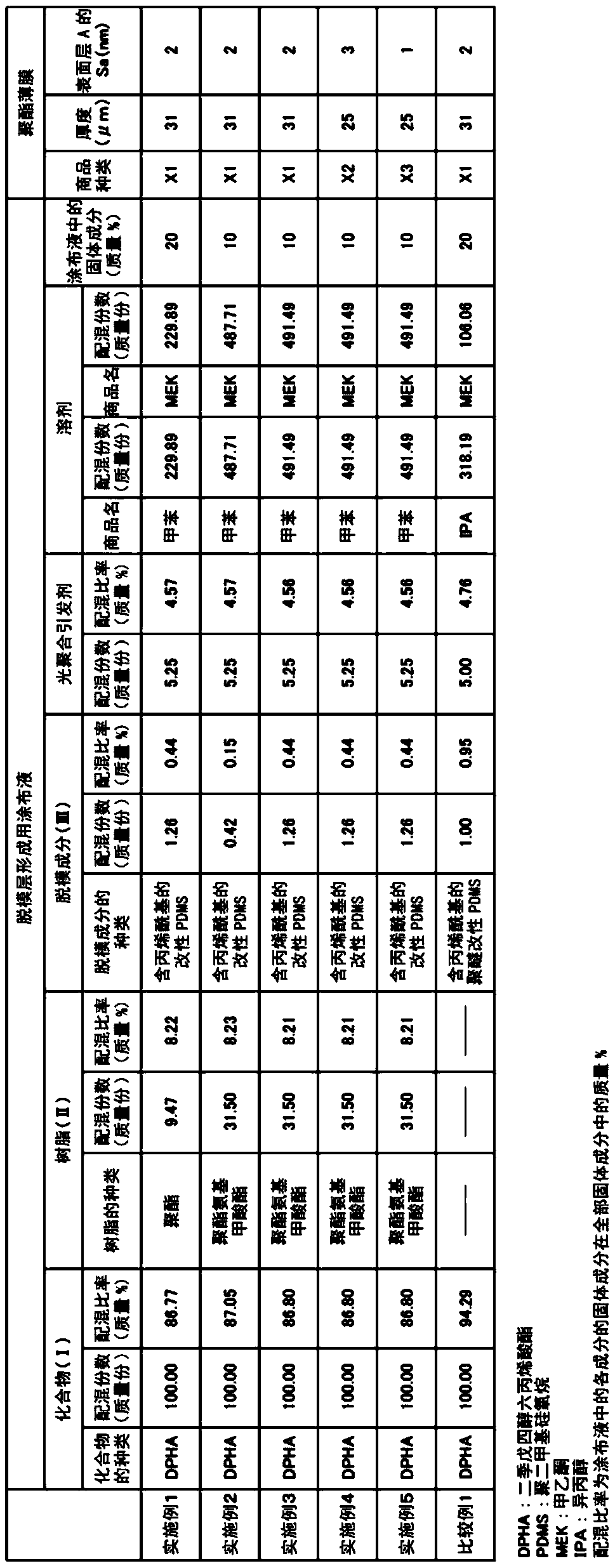

Embodiment 1

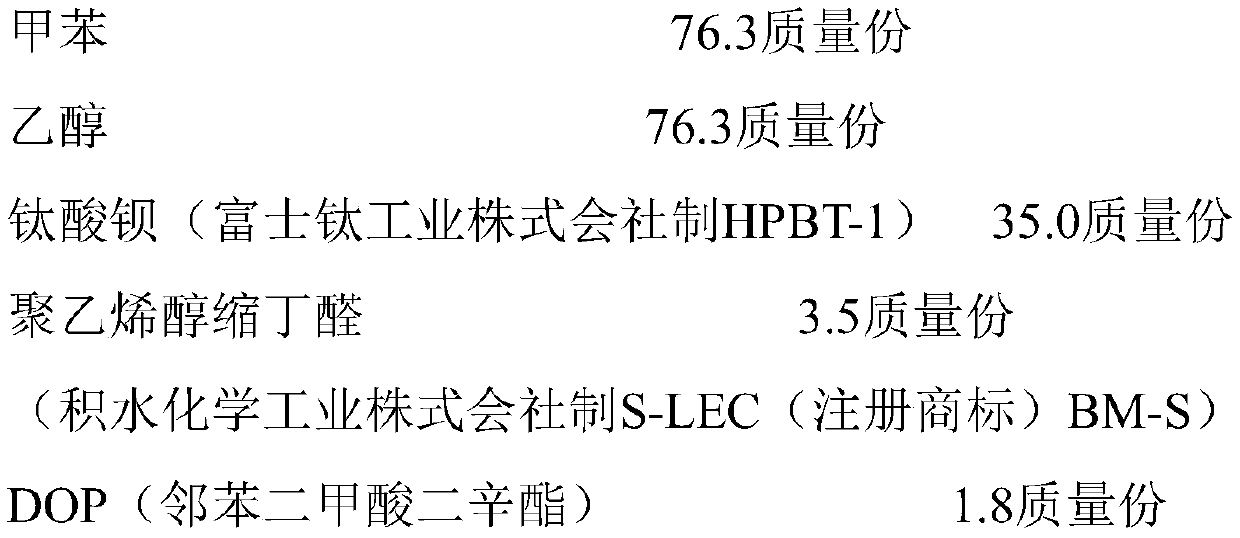

[0143] Using a reverse gravure, coat the coating liquid 1 with the following composition on the surface layer A of the laminated film X1 so that the film thickness of the mold release layer after drying becomes 2.5 μm. After drying at 90°C for 30 seconds, use a high-pressure mercury lamp , irradiate ultraviolet rays to make it 200mJ / cm 2 , so as to obtain a release film for the manufacture of ultra-thin ceramic green sheets. The obtained release film was evaluated for release layer thickness, area surface roughness Sa, maximum peak height Rp, pinhole evaluation of ceramic green sheet, damage evaluation to ceramic green sheet, static friction coefficient, and dynamic friction coefficient.

[0144] (coating liquid 1)

[0145] Compound (I) 100.00 parts by mass

[0146] (Dipentaerythritol hexaacrylate, Shin-Nakamura Chemical Co., Ltd. A-DPH, solid content concentration 100%)

[0147] Resin (II) polyester resin 9.47 parts by mass

[0148] (Vylon (registered trademark) RV280 man...

Embodiment 2

[0155] The resin (II) was changed to a polyester urethane resin (Vylon (registered trademark) UR1400 manufactured by Toyobo Co., Ltd., solid content concentration: 30% by mass), and the following coating solution 2 was used. The solid content concentration of the coating liquid 2 was lower than that of the coating liquid 1 of Example 1. Coating was performed so that the film thickness of the release layer after drying would be 1.5 μm. A release film was obtained in the same manner as in Example 1 except that the coating liquid 2 was used and the film thickness of the release layer after drying was 1.5 μm. The obtained release film was evaluated for release layer thickness, area surface roughness Sa, maximum peak height Rp, pinhole evaluation of ceramic green sheet, damage evaluation to ceramic green sheet, static friction coefficient, and dynamic friction coefficient.

[0156] (coating solution 2)

[0157] Compound (I) 100.00 parts by mass

[0158] (Dipentaerythritol hexaac...

Embodiment 3

[0167] The following coating liquid 3 which increased the ratio of the release agent (III) compared with Example 2 was used. Coating was performed so that the film thickness of the release layer after drying would be 1.8 μm. A release film was obtained in the same manner as in Example 1, except that the coating liquid 3 was used and the film thickness of the release layer after drying was 1.8 μm. The obtained release film was evaluated for release layer thickness, area surface roughness Sa, maximum peak height Rp, pinhole evaluation of ceramic green sheet, damage evaluation to ceramic green sheet, static friction coefficient, and dynamic friction coefficient.

[0168] (coating solution 3)

[0169] Compound (I) 100.00 parts by mass

[0170] (Dipentaerythritol hexaacrylate, Shin-Nakamura Chemical Co., Ltd. A-DPH, solid content concentration 100%)

[0171] Resin (II) 31.50 parts by mass of polyester urethane resin (Vylon (registered trademark) UR1400 manufactured by Toyobo Co....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com