Mixed thermoplastic polyester and thermal-shrinkage double pipe therefrom

A thermoplastic polyester and heat-shrinkable sleeve technology, which is applied in the field of mixed thermoplastic polyester and heat-shrinkable sleeves made of this polyester, can solve the problems of undisclosed, expensive, etc., and achieve a perfect appearance without defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

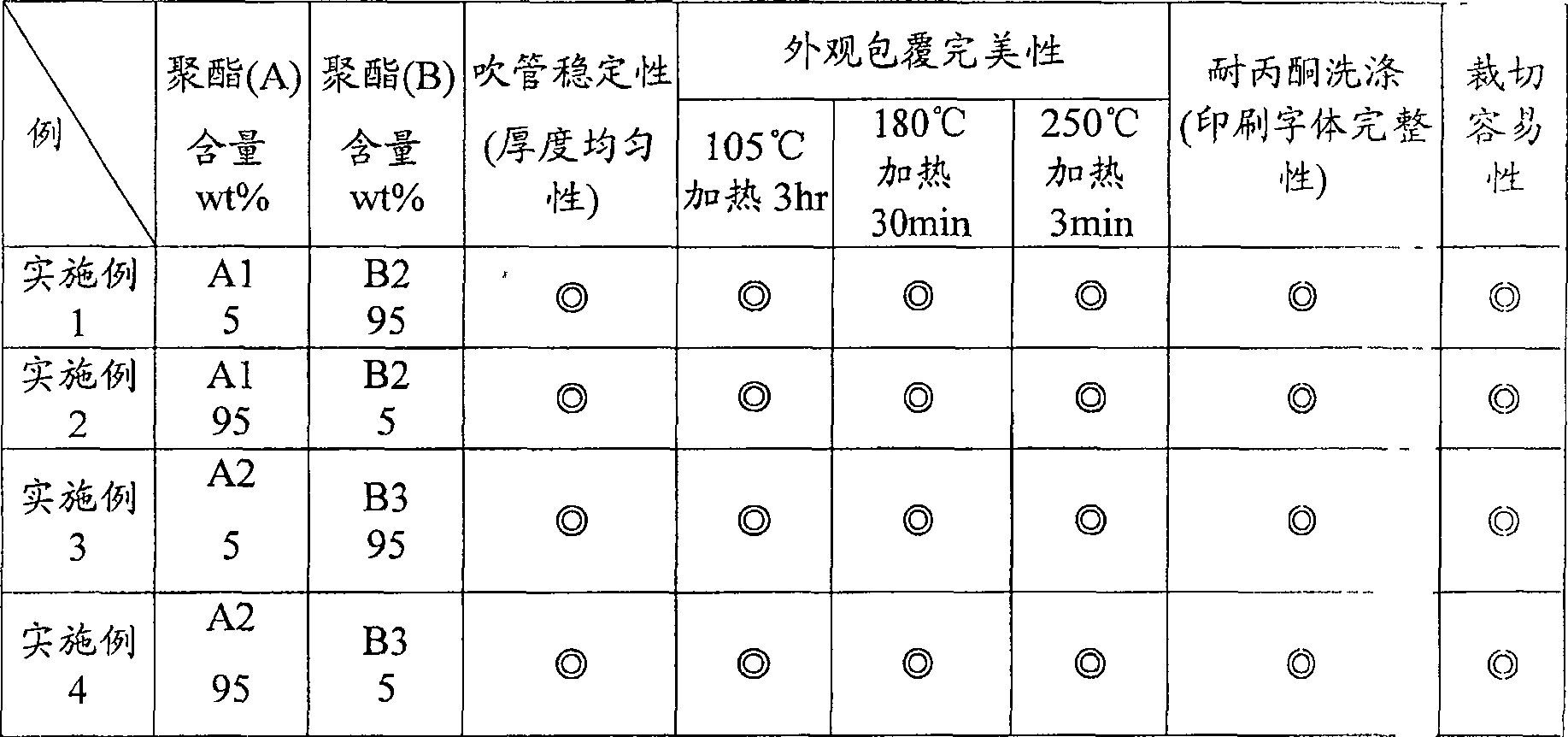

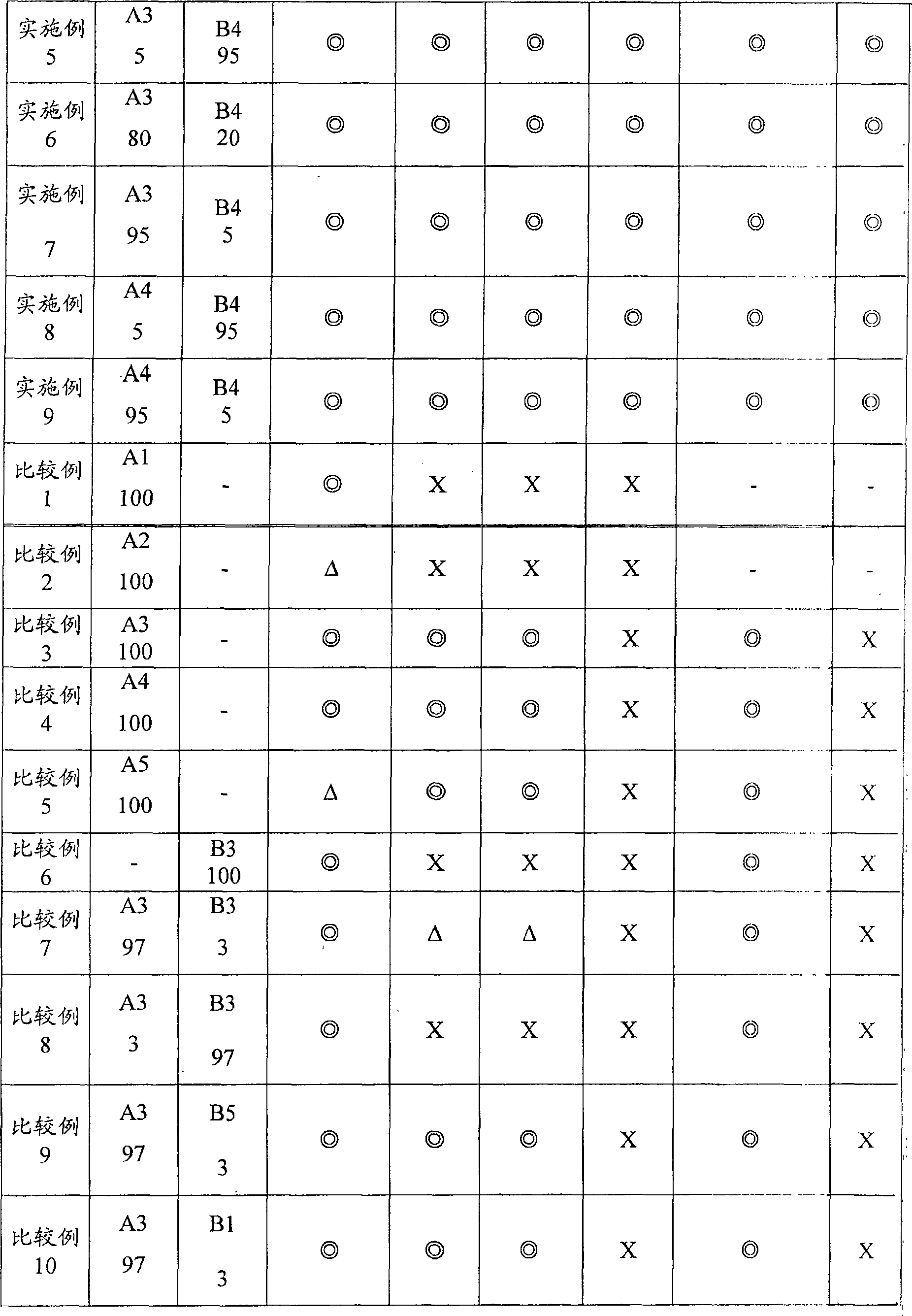

Embodiment 1

[0070] Take 5 parts by weight of polyester A1 and 95 parts by weight of polyester B2, use stirring and mixing equipment to make them evenly mixed, dry the thermoplastic polyester pellets in this mixed state with dehumidified air at 150 ° C for 4 hours, and use an extruder Melt and extrude at 250-270°C, and pass through a ring-shaped die to make a hollow cylindrical unextended original tube, and the original tube is immediately cooled by a cooling water tank, and then, using a set of speed settings The 100rpm feed roller (Feed Roller) makes the original pipe pass through the heater, and when the temperature of the original pipe reaches 90-100°C, pressurized air is introduced to blow and expand the original pipe to a sleeve that is more than 1.3 times the diameter of the original pipe. The expanded tube is pulled out by a set of nip rollers with a rotational speed set at 105 rpm, thus making a heat-shrinkable tube.

[0071] Next, a series of tests were carried out on the heat-sh...

Embodiment 2

[0076] As in Example 1, but the polyester A1 of 95 parts by weight and the polyester B2 of 5 parts by weight are taken, the results are shown in Table 1.

Embodiment 3

[0078] As in Example 1, but get 5 parts by weight of polyester A2 and 95 parts by weight of polyester B3, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com