Method for processing high-precision PCB (Printed Circuit Board) with nonmetal and metal edges

A technology of PCB board and processing method, which is applied in the processing field of high-precision non-metallic and metallized PCB boards, can solve the problems of insufficient precision, unfavorable assembly, manual repair, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

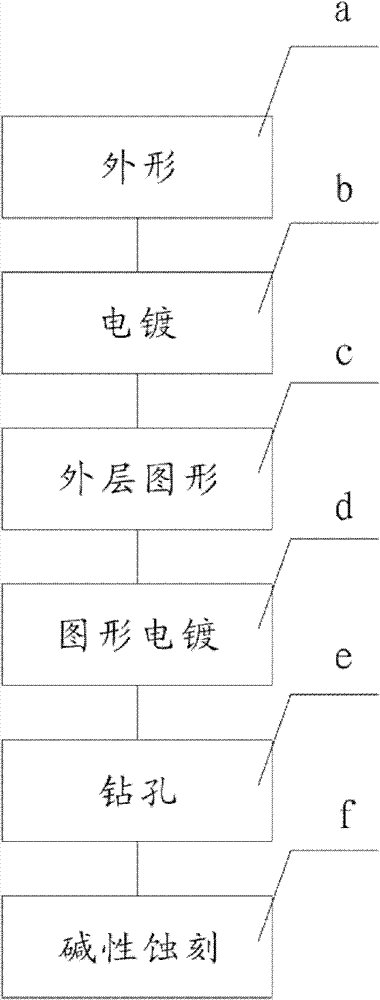

[0034] see figure 1 , the processing method of the high-precision non-metallic PCB board of the present invention, may further comprise the steps:

[0035] a. Shape: directly mill out the shape of the PCB board with a milling machine;

[0036] b. Electroplating: Electroplate a layer of copper on the surface of the PCB board obtained in step a and the non-metallic and metallized edges;

[0037] c. Outer layer graphics: the copper-plated PCB surface obtained in step b needs to be etched to cover the area where the copper is removed;

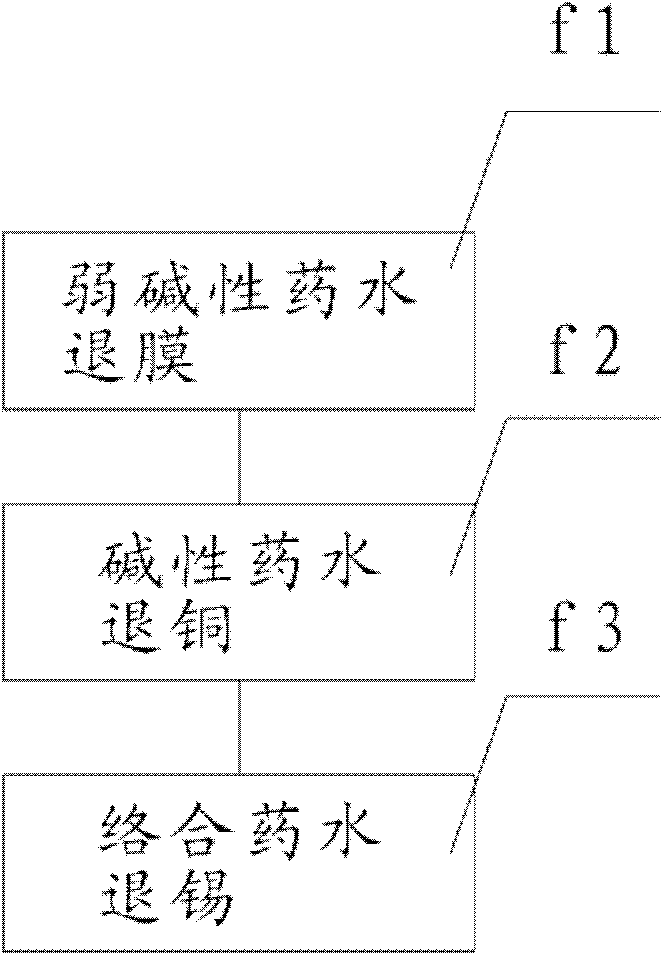

[0038] d. Pattern electroplating: After step c, plate a layer of tin that plays a protective role in etching on the metal area of the PCB surface that is not covered with the dry film and the non-metallic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com