Polyester film with low percent thermal shrinkage and production method thereof

A technology of polyester film and thermal shrinkage rate, which is applied in the field of polyester film with low thermal shrinkage rate and its production field, and can solve the problems of not providing the thermal shrinkage rate of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

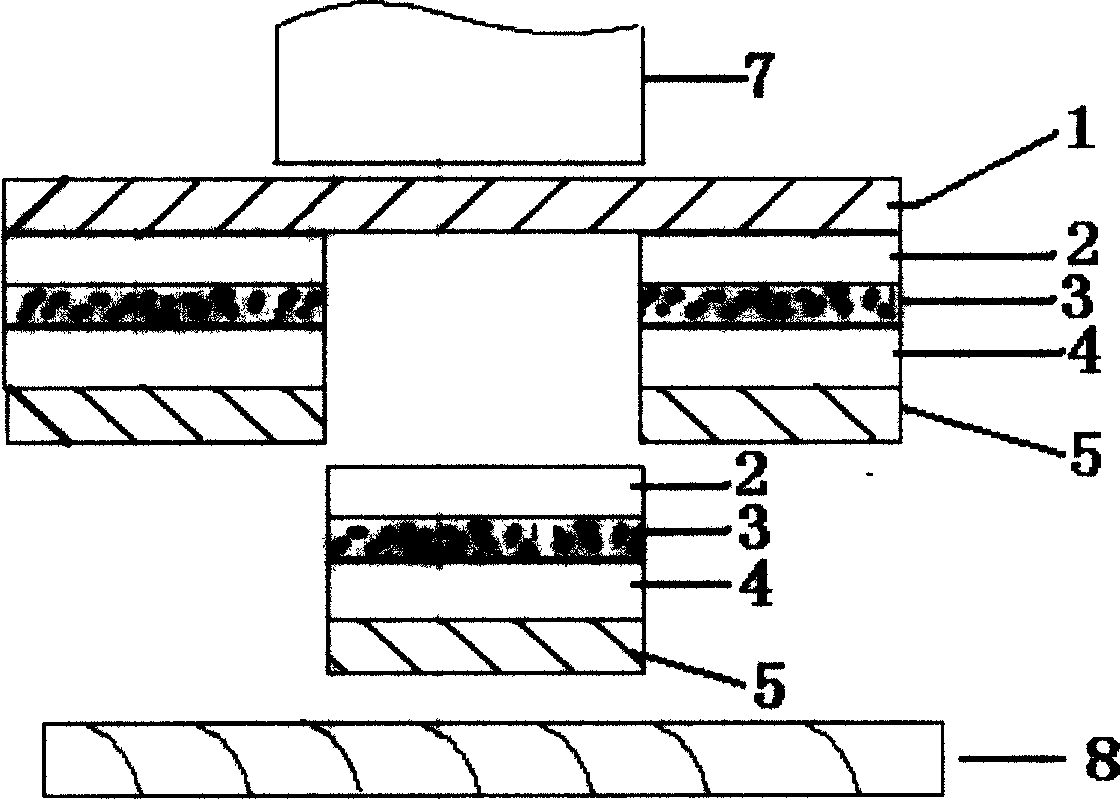

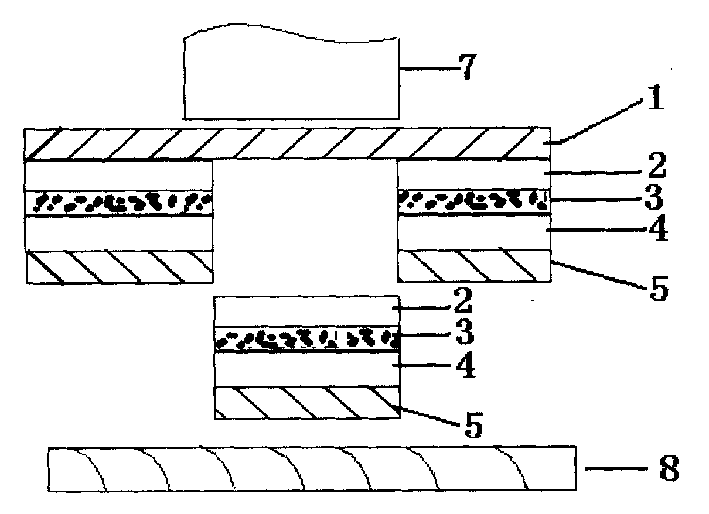

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below through specific embodiments.

[0033] 1. Preparation of polyester raw materials:

[0034] Mix two kinds of silicon dioxide with different particle sizes (see the following conditions for the specific size) in ethylene glycol to prepare a silicon dioxide suspension in ethylene glycol, and produce polyester according to the conventional polymer synthesis method (PTA method) Slice, first carry out esterification reaction, then carry out polycondensation reaction, add the ethylene glycol suspension of silicon dioxide and the polycondensation catalyst in the prior art, stabilizer before polycondensation, at 280 ℃, vacuum degree 10-66.7Pa, stir The speed is 40rpm, the reaction time is between 2-3 hours, and the mother slice is made, the mother slice M 1 Contains Fuji silicon S350 (spherical, FUJI SIL YSIA CHEMICALLTD.JAPAN) (particle size 1.8μm) 3000ppm, mother chip M 2 Contains Fuji Silicon S350 (particle size: 1.8μm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com