High definition multimedia interface (HDMI) linear material

A wire and core wire technology, applied in the direction of conductors, metal/alloy conductors, insulated cables, etc., can solve the problems of poor welding performance and large outer diameter of wires, and achieve good welding performance, save loss costs, and be easy to carry.

Inactive Publication Date: 2011-04-20

SUZHOU YIHUA COMMUNICATED CONNECTOR

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

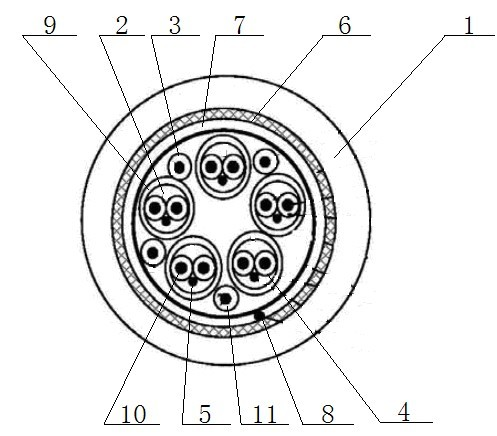

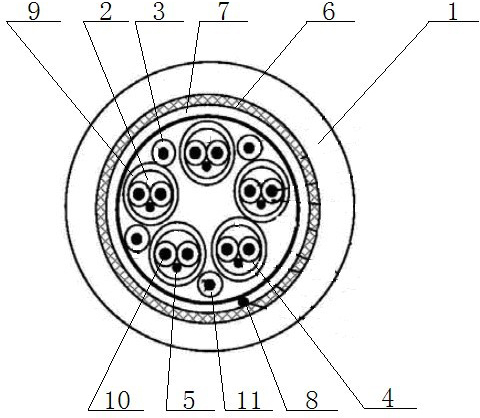

The invention discloses a high definition multimedia interface (HDMI) linear material, comprising a core wire, at least one external paired core wire and a core wire jacket, wherein, the inner part of the core wire is provided with inlayer aluminum mylar foil, an internal paired core wire, inner cascading water earth wires and anti-electromagnetic interference earth wires, and the outer part of the core wire is coated with outer-layer aluminum mylar foil, anti-electromagnetic interference braided-layer core wires and the core wire jacket; the inner paired core wire and the external paired core wire are in a round layered structure which comprises a conductor layer and an insulating layer arranged outside the conductor layer; the specification of the manufacturing material of the conductor layer is 36AWG (American wire gauge) of tinned cooper wires; the core wire jacket is made of Teflon; and the external diameter of the core wire jacket is 3.6+ / -0.15 millimeters. The linear material provided by the invention not only has smaller wire material outer diameter, but also has better welding performance.

Description

technical field [0001] The invention relates to a wire, in particular to an HDMI wire, which is particularly suitable for use on small electronic products. Background technique [0002] With the advent of the high-definition digital era, HDMI (High Definition Multmedia Interface, high-resolution multimedia digital transmission interface) cable is a high-frequency cable for high-definition digital video signal transmission, mainly used in TVs, DVDs, computers and other products. At present, the outer diameter of standard HDMI cables on the market is more than 4 mm. In view of the current trend of miniaturization of electronic products, especially the mobile phone industry needs to use ultra-small cables to directly transmit images to TV / projection equipment, and the outer diameters of existing products are all More than 4 mm, so the existing products cannot meet the existing market demand. At the same time, with the reduction of the outer diameter of the wire rod, problems s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B7/00H01B7/17H01B1/02

Inventor 宁立平

Owner SUZHOU YIHUA COMMUNICATED CONNECTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com