Film covering device and method of wing structure surface

A technology of wing structure and film, applied in the field of large-scale lightweight aircraft structure manufacturing, can solve the problems of poor environmental resistance and low mechanical properties of heat-shrinkable film, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

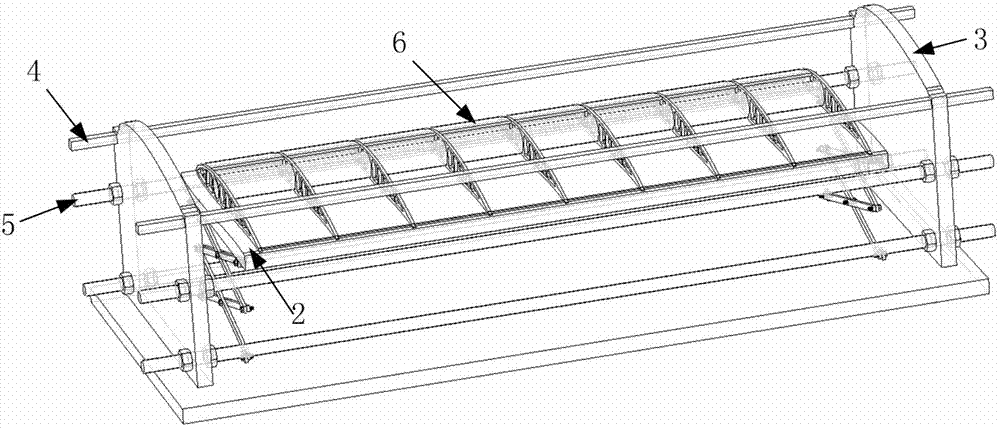

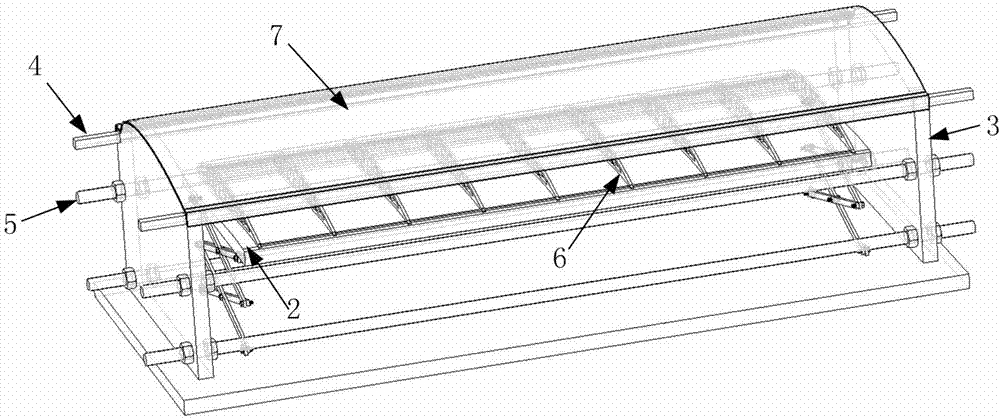

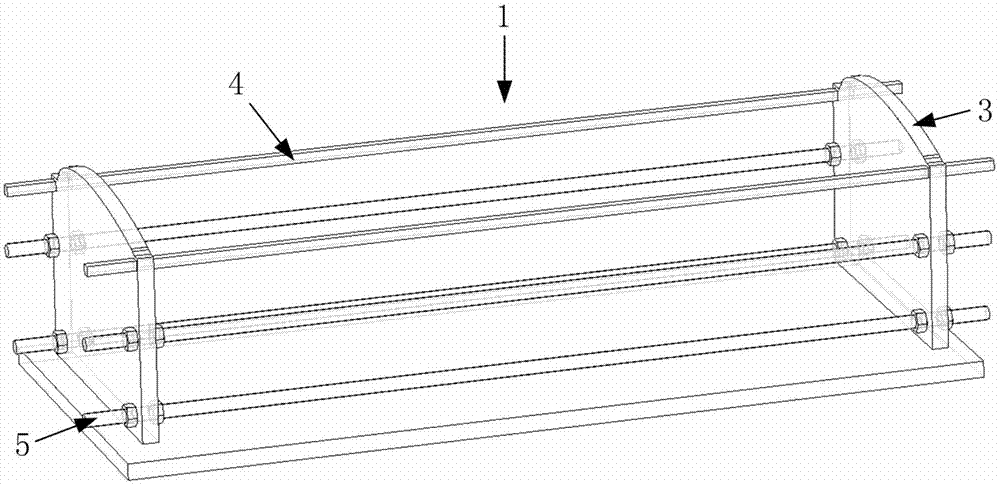

[0023] a kind of like figure 1 , figure 2 , image 3 The covering device of the wing structure surface film of the present invention is shown, the covering device includes a film tensioning mechanism 1 and a wing supporting device for pressing the wing structure frame 6 against the tensioned polyester film 7 . The wing supporting device of this embodiment is a lifting platform 2, and the top of the lifting platform 2 is provided with a support surface capable of fixing the wing structure frame 6. There is a certain distance between the supporting surface of the lifting platform 2 and the film fixing surface of the film tensioning mechanism 1, and the supporting surface and the film fixing surface can be continuously approached by the relative displacement and realize the tension of the wing structure frame 6 to the tensioned polyester film 7. lean on.

[0024] The film tensioning mechanism 1 of this embodiment includes movable spanwise end plates 3 located on both sides. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com