Automobile combined rear lamp structure

A technology for rear lights and automobiles, which is applied to vehicle parts, lighting and heating equipment, transportation and packaging, etc. It can solve the problem of insufficient bonding between the light distribution mirror and the lamp housing, imperfect gluing process, and affecting service life, etc. problems, achieve the effect of guaranteeing precision requirements, long service life and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

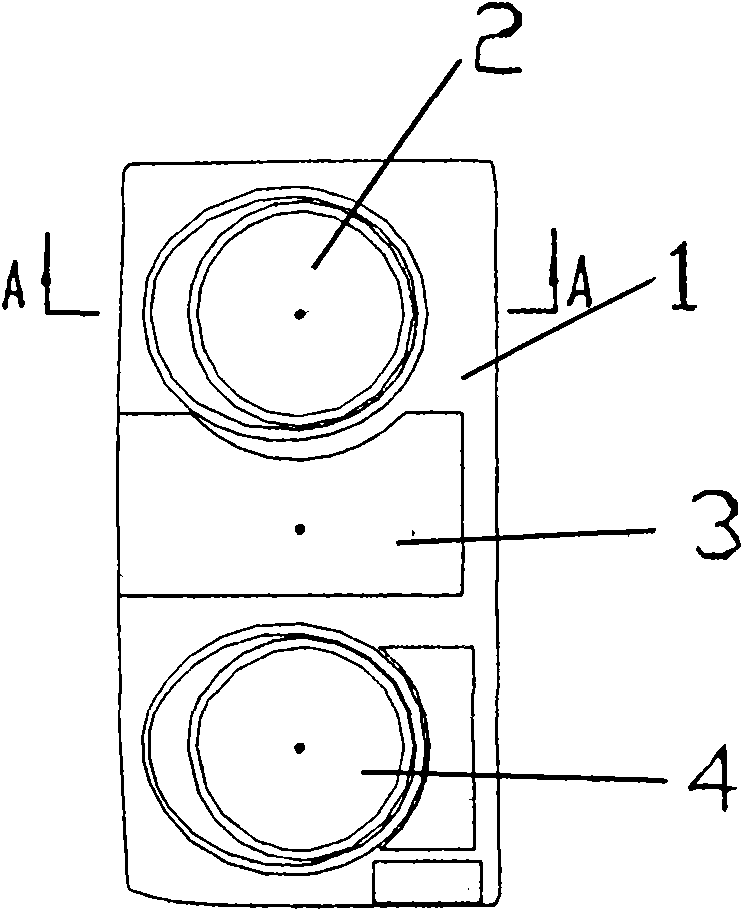

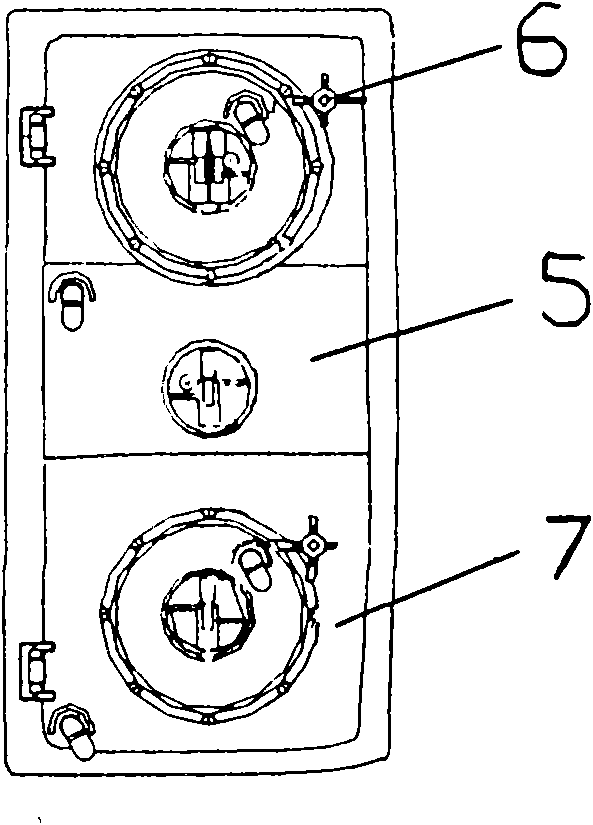

[0020] see figure 1 , figure 2 , image 3 with Figure 4 A combined rear lamp structure for automobiles shown, including a lamp housing 5, a brake lamp / rear position lamp 2, a rear turn signal lamp 3 and a rear fog lamp / reversing lamp 4 arranged on the lamp housing;

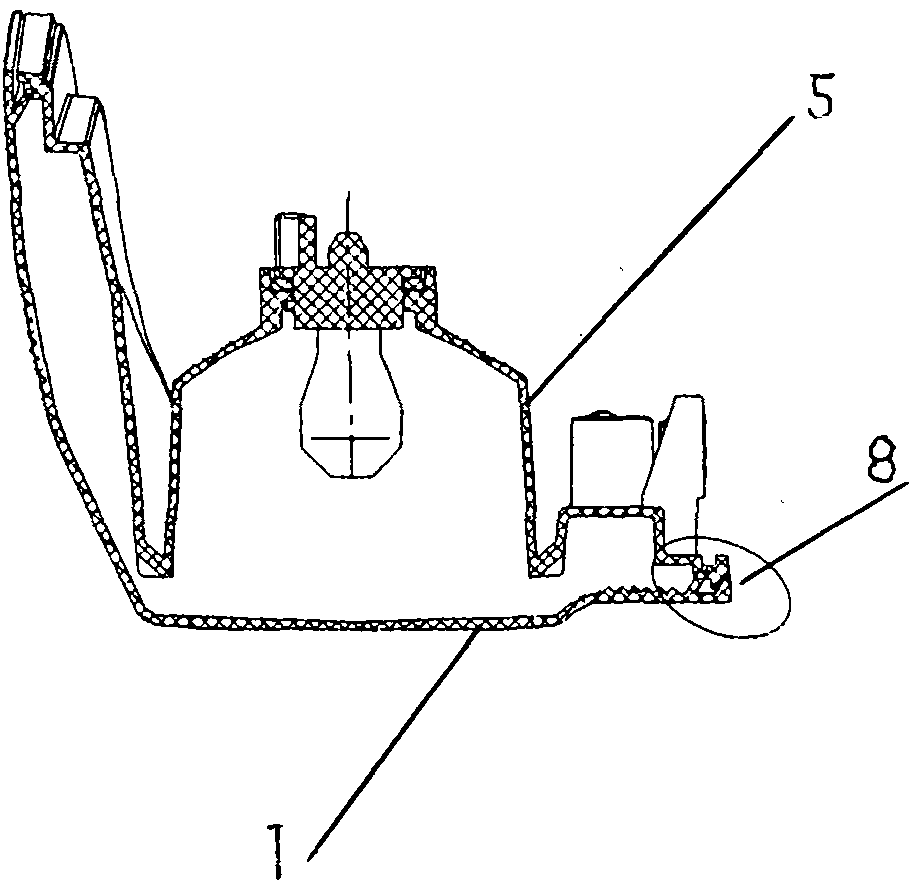

[0021] A light distribution mirror 1 includes a yellow turn signal light distribution mirror and a white reversing light distribution light distribution mirror. The yellow turn signal light distribution mirror and the white reversing light distribution light distribution mirror are directly embedded in the light distribution mirror 1. There is a welding limit rib 8 on the side, which protrudes upwards, and its vertical section is approximately trapezoidal, and is fixedly connected with the welding rib on the right side of the lamp housing 5 by means of hot plate welding;

[0022] A main positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com