Combustion chamber of a pulse detonation engine

A technology of pulse detonation and combustion chamber, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc. It can solve the problems of large influence of flow resistance and ablation, and achieve the reduction of frontal flow resistance, increase of thrust, and not easy to burn Eclipse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a pulse detonation engine combustion chamber.

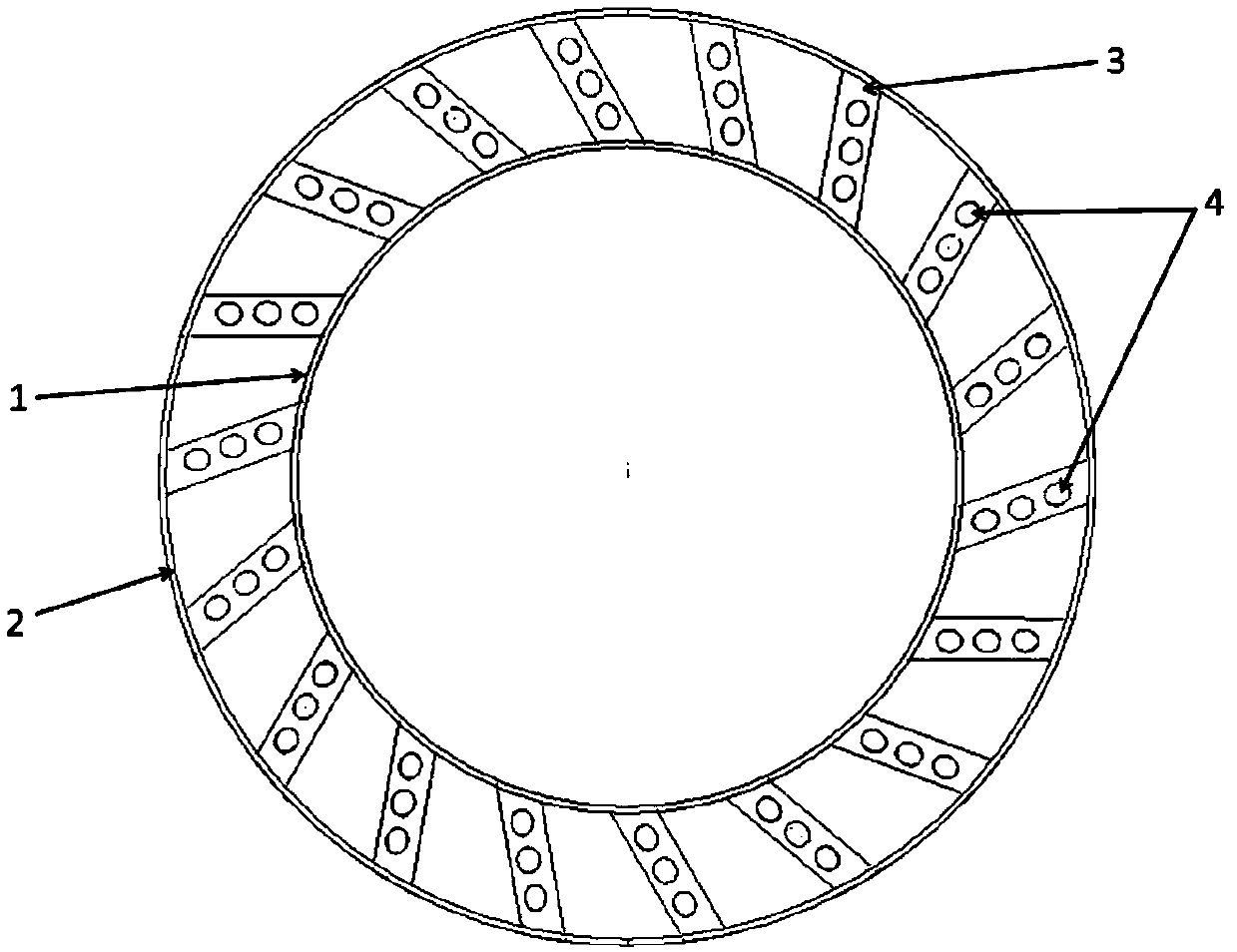

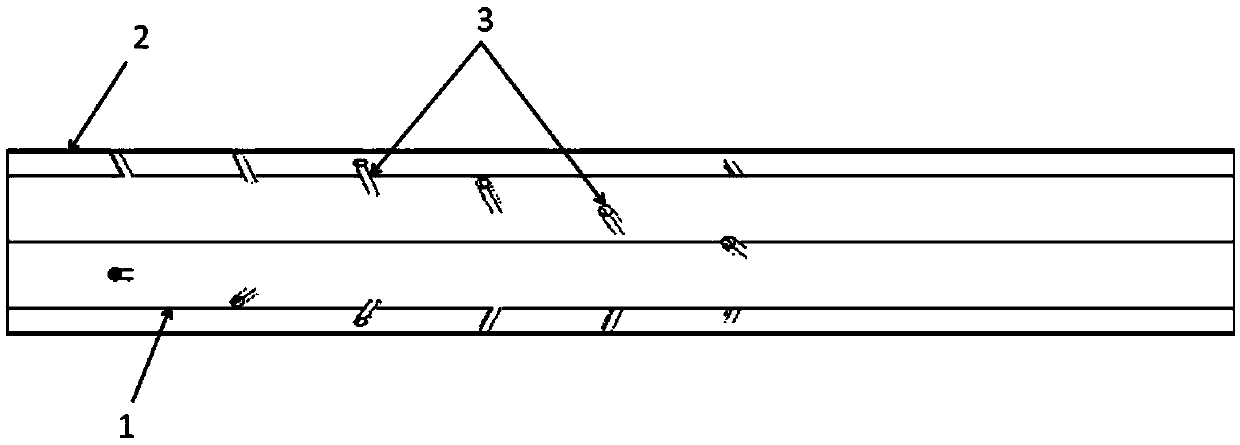

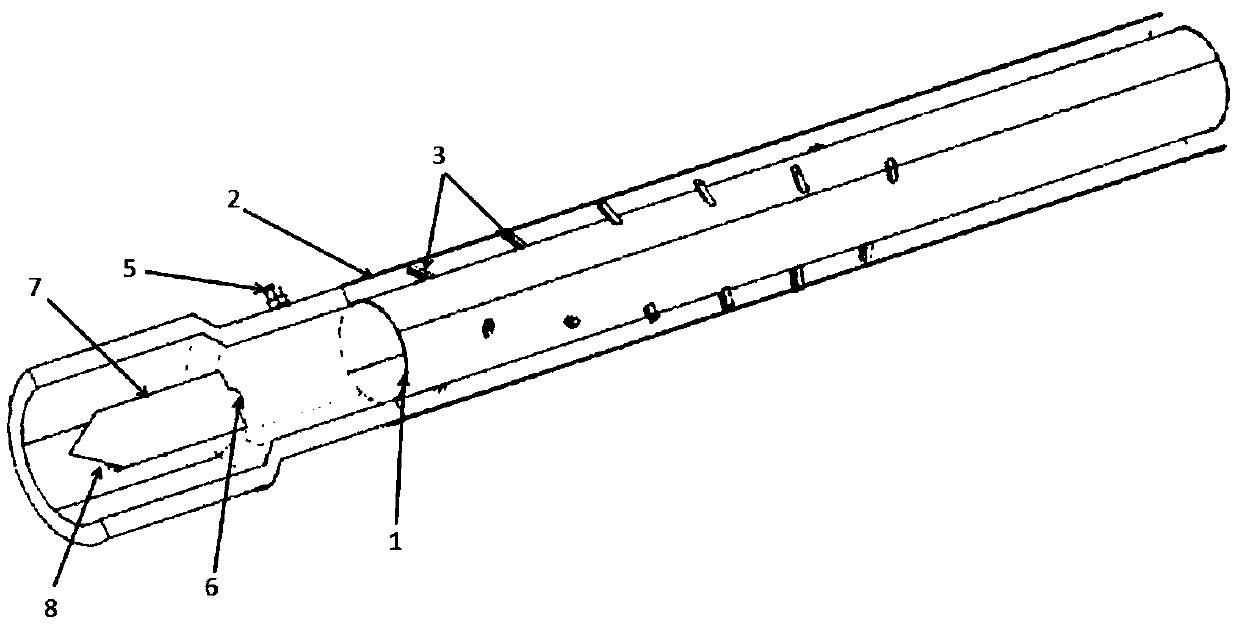

[0021] refer to figure 1 , figure 2 , the combustion chamber of the pulse detonation engine in this embodiment includes a combustion chamber wall surface 1, an air inlet casing 2, a drainage section 3, and an air intake hole 4, wherein, the air inlet casing 2 and the combustion chamber wall surface 1 are provided with Multi-row air intake devices, each exhaust dynamic air intake device is separated by 0.5 to 1 times the diameter of the combustion chamber. The air intake device is composed of a drainage section 3 and an air intake hole 4, and the air channel casing 2 forms a circular secondary air intake channel. The drainage section 3 is a hollow cylinder connecting the inlet casing 2 and the wall of the engine. The cylinder has the same inclination along the axial and circumferential directions of the engine, and a plurality of air inlets are arranged on the front wall of the cylinder. Multiple rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com