Cathode cooling structure of plasma spraying gun

A cooling structure, plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problem that the cathode is easy to be ablated, and achieve the effect of simple production, excellent thermal conductivity, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

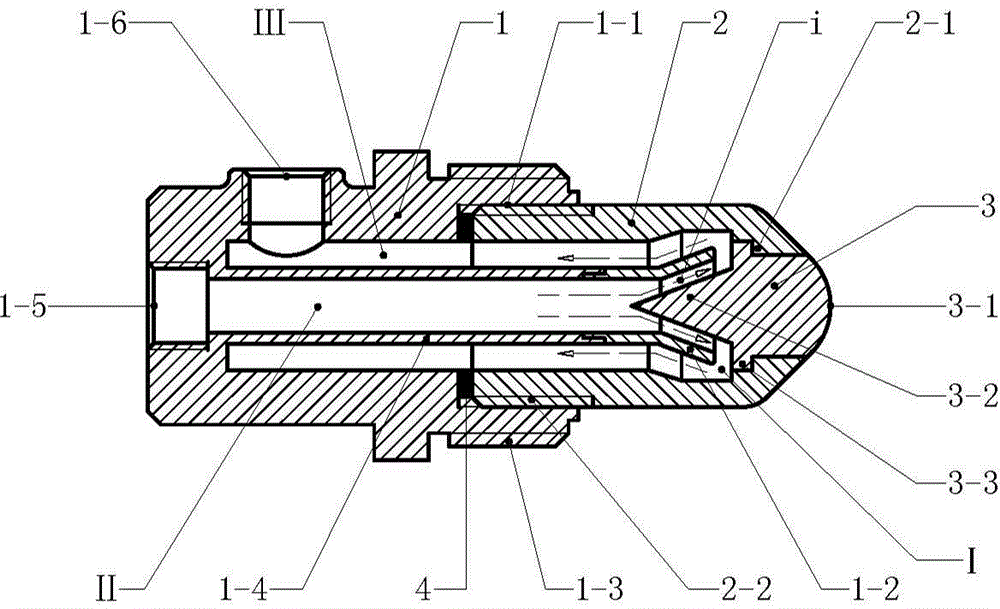

[0014] Example 1 figure 1In the embodiment shown, the cathode cooling structure of the plasma torch is composed of a back seat (1), a cathode sleeve (2) and a cathode head (3), wherein the back seat (1) is a hollow rotary structure, and the back seat ( 1) There are diversion pipes (1-4) in the rotator structure of the rear seat (1), and there are cooling water input ports (1-5) and cooling water output ports (1-6) on the rotator structure of the rear seat (1). There are threaded notches (1-1) on the inner side of the front wall of the back seat (1) rotator, and connecting threads (1-3) on the outer side of the back seat (1) rotator; the cathode sleeve (2) is a hollow rotator structure, there is a mounting screw (2-2) on the outside of the wall at the rear of the cathode sleeve (2), and the mounting screw (2-2) cooperates with the threaded notch (1-1) on the rear seat (1), The front end of the cathode sleeve (2) is a truncated conical structure that shrinks from the back to ...

Embodiment 2

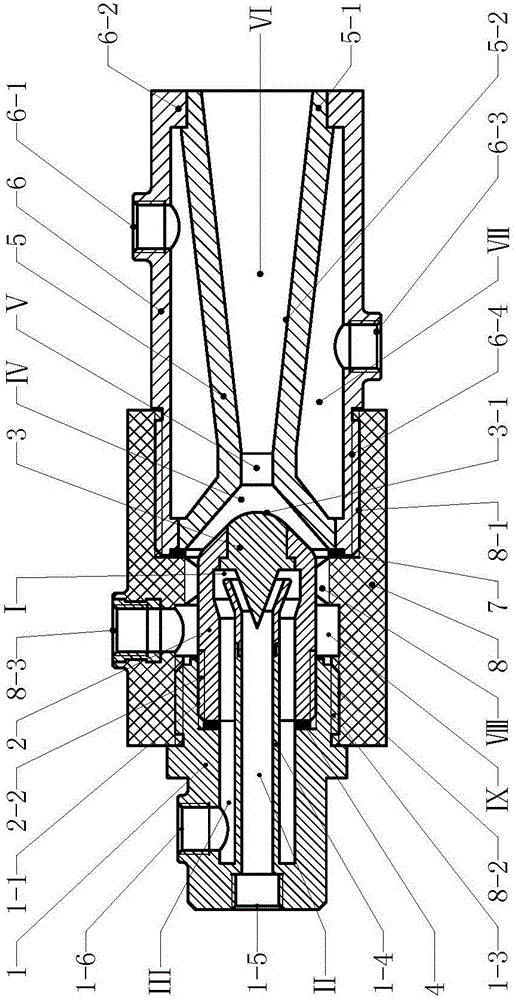

[0015] Example 2 figure 2 The embodiment shown is the application of the present invention on the plasma spray gun, and the plasma spray gun is mainly composed of a back seat (1), a cathode cover (2), a cathode head (3), an insulating gun frame (8), an anode cover (6 ) and the anode (5), wherein the rear seat (1), the cathode sleeve (2) and the cathode head (3) constitute the cathode cooling structure, which is the same as the structure in the first implementation and will not be described in detail; the insulating gun frame (8 ) is a hollow revolving body structure, the front and rear mounting grooves (8-1) and rear mounting grooves (8-2) of the insulating gun frame (8) are respectively provided, and the rotating body structure of the insulating gun frame (8) has an air chamber (Ⅸ), the air chamber (Ⅸ) is connected to the working gas input interface (8-3); the anode sleeve (6) is a cylindrical structure, and the outside of the rear wall of the anode sleeve (6) has mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com