Double-break isolating switch and GIS equipment

An isolating switch and double-break technology, which is applied in the setting of switchgear, switchgear, air switch parts, etc. The effect of clever construction, long life and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

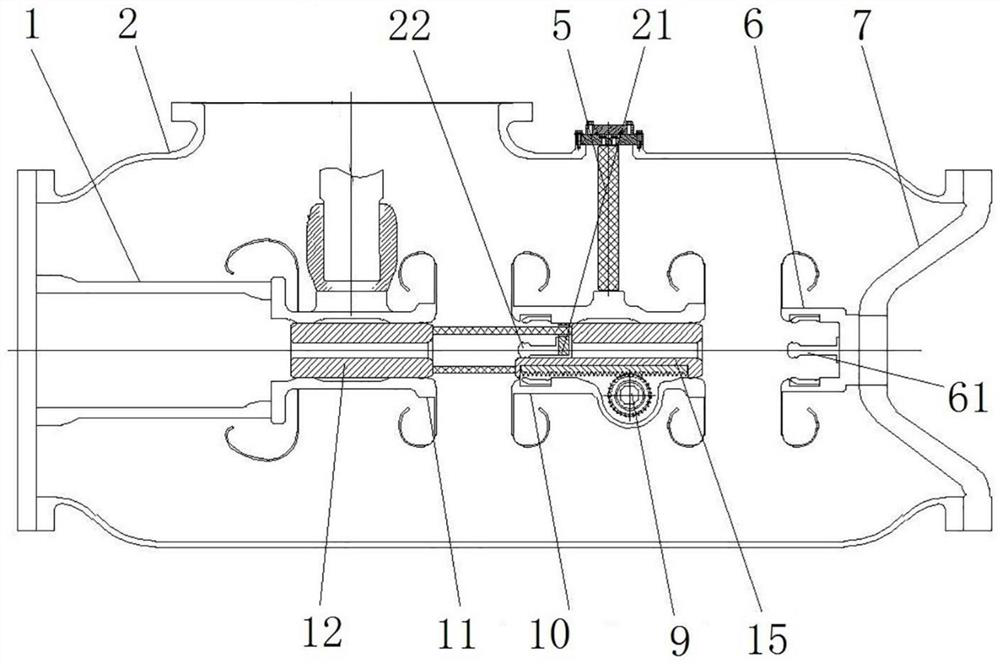

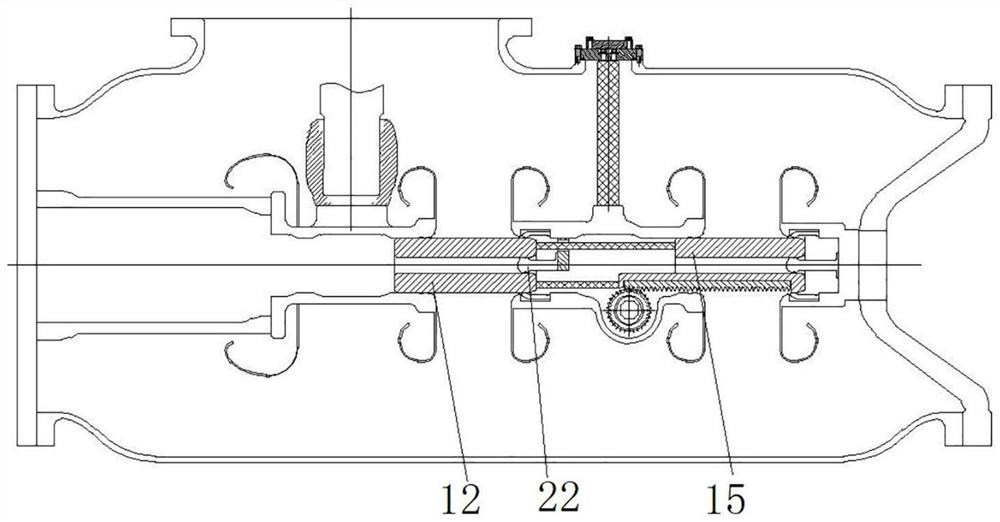

[0062] The GIS equipment of the present invention includes a bus bar, a circuit breaker, a grounding switch and a double-break disconnecting switch.

[0063] like figure 1 and 2 As shown, the double-break disconnect switch includes a housing 2, an insulating support cylinder 1 is fixed on one side of the inner cavity of the housing 2, and a first movable contact seat 11 is fixed on the insulating support cylinder 1. An insulating pot 7 is fixed on the other side, a static contact seat 6 is fixed on the insulating pot 7 , and an arc striking contact 61 of the static contact seat is fixed on the bottom wall of the inner hole of the static contact seat 6 . An insulating support 5 is fixed on the inner wall of the housing in the middle of the inner cavity of the housing 2 , and a second movable contact seat 10 , a first movable contact seat 11 , a second movable contact seat 10 and a static contact seat are fixed on the insulating support 5 6 are arranged at intervals and form t...

Embodiment 1

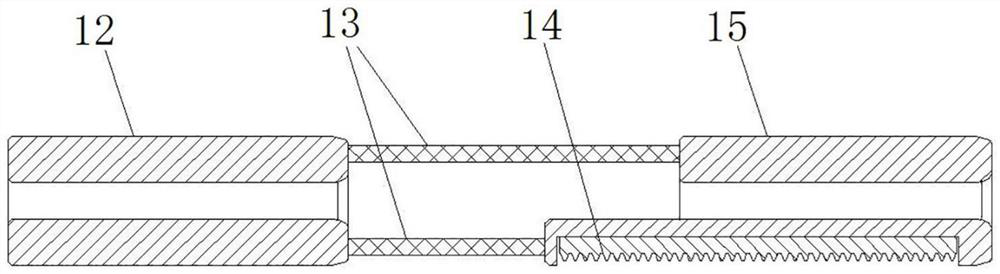

[0072] The connection block in the first embodiment is integrally arranged with the second movable contact seat. In this embodiment, the connection block is welded on the hole wall of the second movable contact mounting through hole.

specific Embodiment 3

[0074] The insulating connectors in Embodiment 1 are four insulating rods spaced along the circumference of the end face of the first movable contact. In this embodiment, the insulating connectors are insulating cylinders connecting two movable contacts. The end of the 1 is provided with a connecting block with the same structure as the connecting block in Embodiment 1, so as to connect the two moving contacts. In order to avoid the arc-striking contact, the insulating cylinder is provided with an escape groove. The avoidance groove is mainly to avoid the connection block of the arc-striking contact, and the inner cavity of the insulating cylinder is mainly to avoid the contact body of the arc-striking contact.

[0075] In addition, for the case where the second movable contact is provided with an avoidance notch, the insulating cylinder is formed with a circular arc tube segment complementary to the avoidance notch on the second movable contact by cutting, and the avoidance gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com