Lock pin type synchronous ring

A technology of synchronous ring and synchronous ring cone, which is applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of harsh working environment requirements, easy to fall off, low ratio, etc., achieve good oil discharge and heat dissipation performance, increase contact area, Effect of increasing sync capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

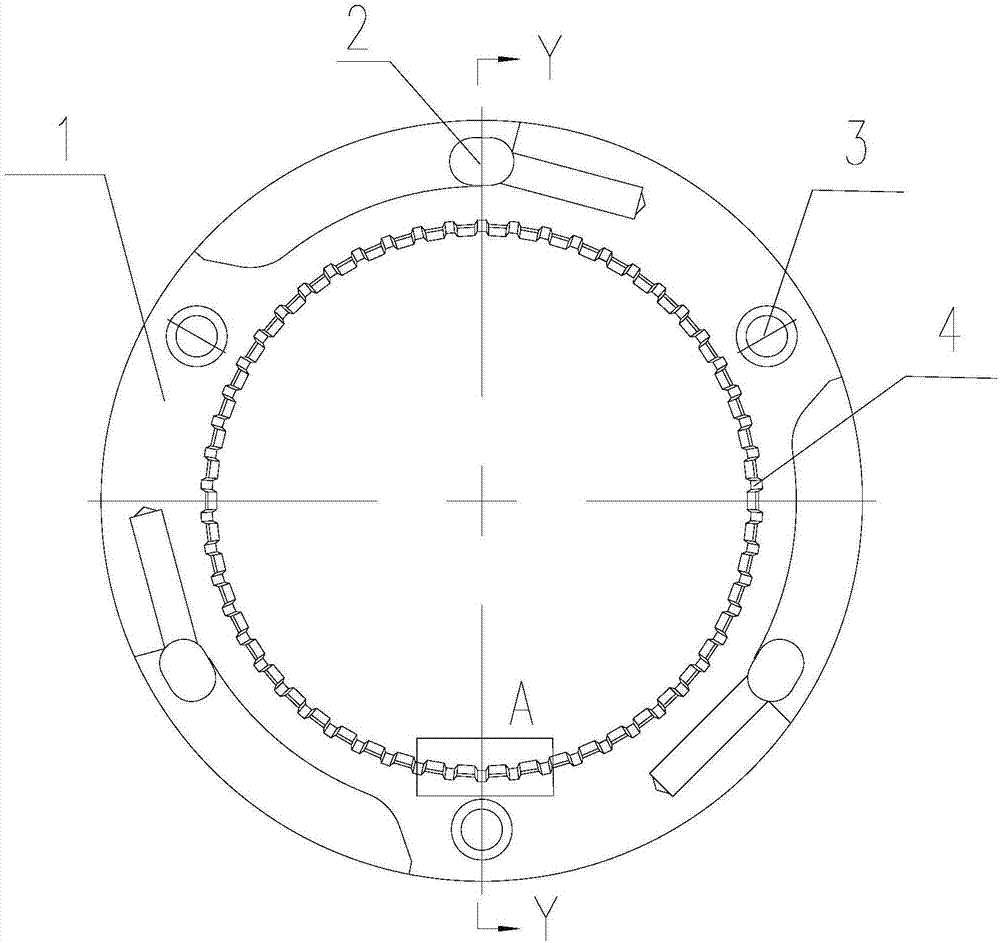

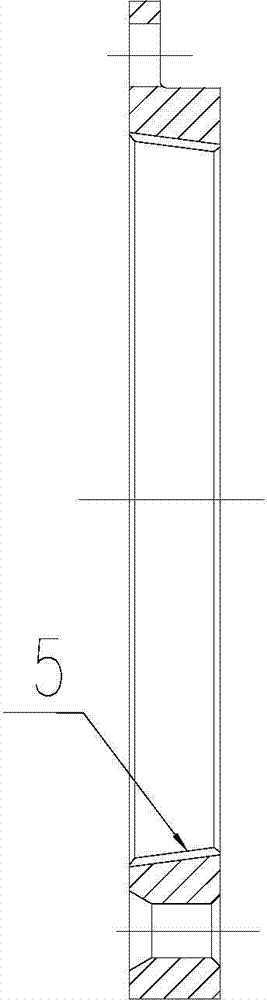

[0028] This embodiment is the high-grade synchronous ring of the present invention.

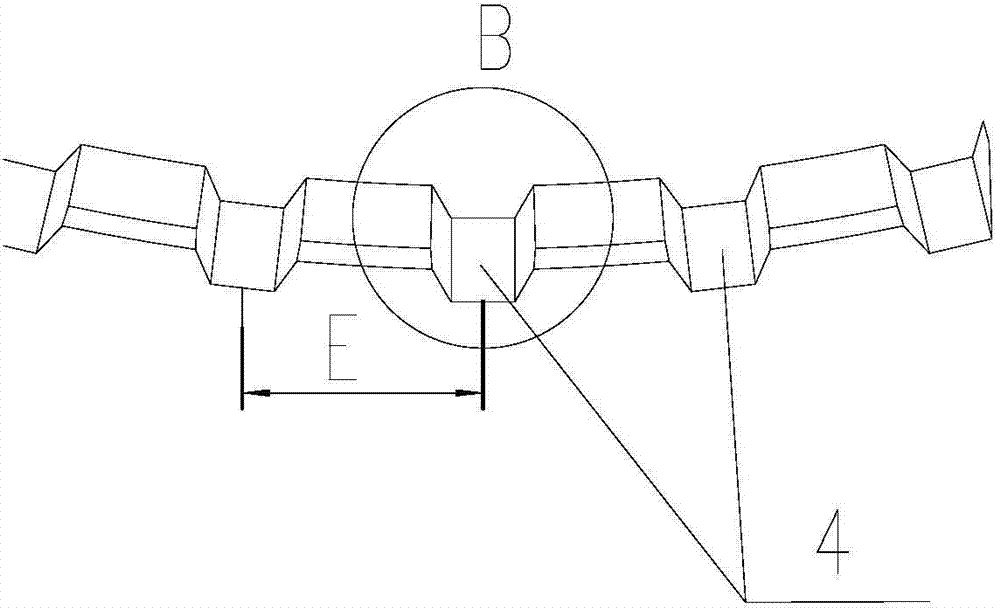

[0029] Such as Figure 1-Figure 4 As shown, the high-grade synchronous ring includes a synchronous ring end face 1 , an adjustment limit hole 2 , a connecting hole 3 , an axial oil groove 4 and a synchronous ring tapered surface 5 . Its main dimensions are: the diameter of the cone surface is 130mm; the cone surface 5 is evenly distributed with axial oil grooves 4, the groove width D is 3mm, the groove depth C is 0.9mm, the groove distance E is 7.1mm, the ratio of groove width to groove depth is 3.33, and the groove width is 3.33. The width to groove pitch ratio is 42%, the length L is 10mm; the angle θ on both sides of the oil groove is 30°. Molybdenum is sprayed on the conical surface 5 of the synchronous ring, and the thickness of the molybdenum layer is 0.1mm. The effective friction area ratio of the cone surface is 57.1%, the friction torque is 77.3N.m, and the oil discharge area is 12...

Embodiment 2

[0031] This embodiment is the low gear synchronizing ring of the present invention.

[0032] Such as Figure 5 , Figure 6 As shown, the low gear synchronous ring includes a synchronous ring end surface 1 , a connecting hole 3 , a synchronous ring tapered surface 5 and an engagement groove 6 . The diameter of the conical surface is 200mm synchronous ring, and the axial oil grooves 4 are evenly distributed on the conical surface 5; The ratio is 39%, the length is 22mm; the angle on both sides of the oil groove is 30°. Molybdenum is sprayed on the conical surface 5 of the synchronous ring, and the thickness of the molybdenum layer is 0.2mm. The effective friction area ratio of the cone surface is 60.8%, the friction torque is 95.2N.m, and the oil discharge area is 191mm 2 .

Embodiment 3

[0034] The comparative detection data of the improved synchronous ring of the embodiment of the present invention and the synchronous ring of the same specification in the prior art 3 are as follows:

[0035]

[0036] Note: The diameter of the synchronous ring cone surface of this embodiment and prior art 3 is 124mm.

[0037] Compared with the synchronous ring of the prior art, the present invention has improved effective friction area, friction torque, and oil discharge area, can improve the gear shifting performance of the synchronizer, improves the gear shifting performance of the synchronizer, and has more excellent oil discharge Heat dissipation performance, under the same conditions, the performance of withstanding the high temperature generated during work is better. Moreover, due to the increased contact area, the tapered surface wears slowly, which improves the service life of the synchronizer. It is especially suitable for the use requirements of the gearbox sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com