Composite cathode for plasma spray gun

A composite cathode and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problem of easy ablation of the cathode, and achieve the effects of not easy to ablate, improve processing efficiency, and large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

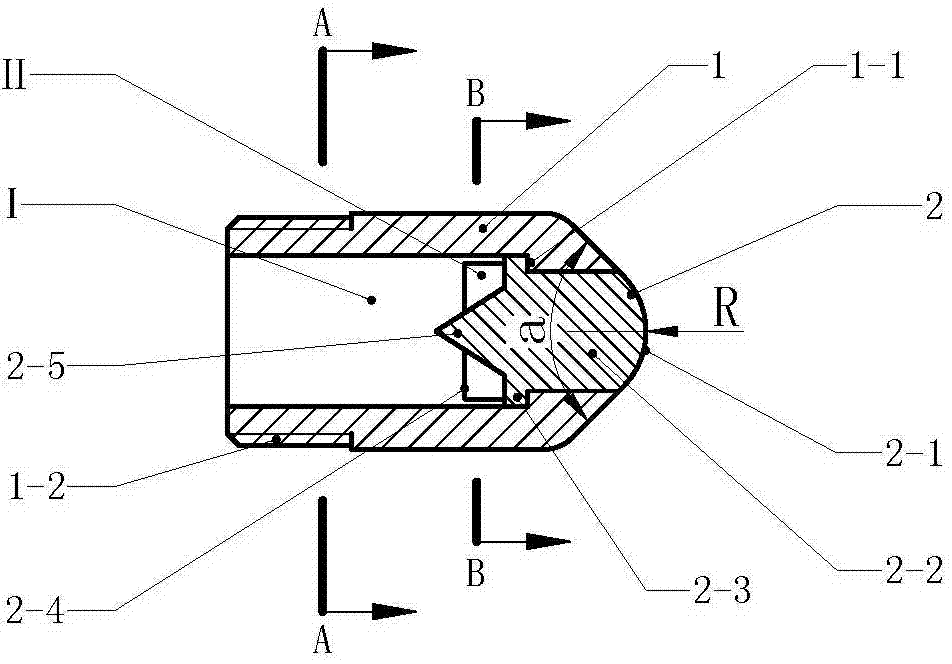

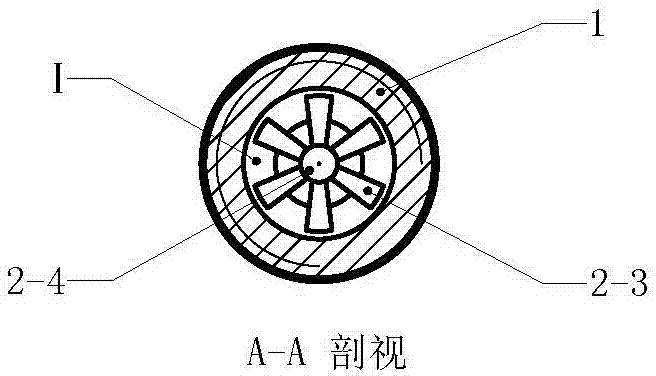

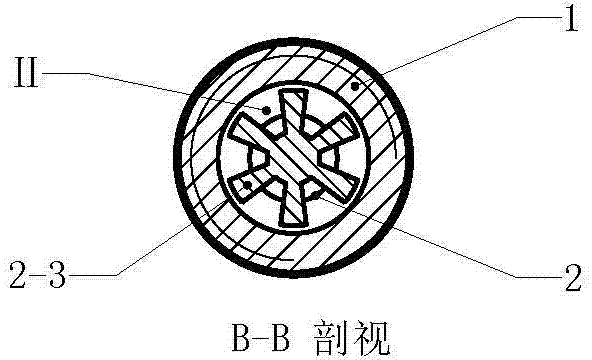

[0015] Example 1 figure 1 In the embodiment shown, a composite cathode for a plasma torch is composed of a cathode casing (1) and a cathode head (2), wherein the cathode casing (1) is a hollow rotary body structure, and the cathode casing (1 ) has a limited step ring (1-1) on the inside of the front end, and a mounting screw (1-2) on the outside of the rear of the cathode sleeve (1), and the front end of the cathode sleeve (1) is a frustum of cone structure that shrinks from the back to the front , the conical angle (a) is 60°-120°; the cathode head (2) is embedded in the inner space at the front of the cathode sleeve (1), and the front end of the cathode head (2) protrudes from the cathode sleeve (1), The front end of the cathode head (2) is a circular arc surface, the radius (R) of the arc at the end of the cathode head is 10 mm, the embedded section (2-2) of the cathode head (2) is a cylindrical structure, and the insertion of the cathode head (2) There is a flange (2-3)...

Embodiment 2

[0016] Example 2 Figure 4 The embodiment shown is the application of the present invention on the plasma torch, and the plasma torch is mainly composed of a back seat (8), a composite cathode, an insulating gun frame (5), an anode sleeve (4) and an anode (3), wherein , the structure of the composite cathode is the same as that in the first implementation, and will not be repeated; the rear seat (8) is a hollow rotary body structure, and there is a screw groove (8-4) on the inner side of the front part of the rotary body of the rear seat (8). There is connecting thread (8-5) on the outside of the front part of the rear seat (8), and the composite cathode is installed on the screw groove (8-4) at the front part of the rotary body of the rear seat (8), and the rotation of the rear seat (8) There is a guide tube (8-2) in the body structure, and the guide tube (8-2) extends into the cooling cavity (I) in the composite cathode and is close to the guide cone (2-5), and the guide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com