Additive manufacturing device and method

A technology of additive manufacturing and cathode, which is applied in the field of additive manufacturing, can solve problems such as beam spot quality degradation, and achieve the effects of improving quality, increasing life, and facilitating manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

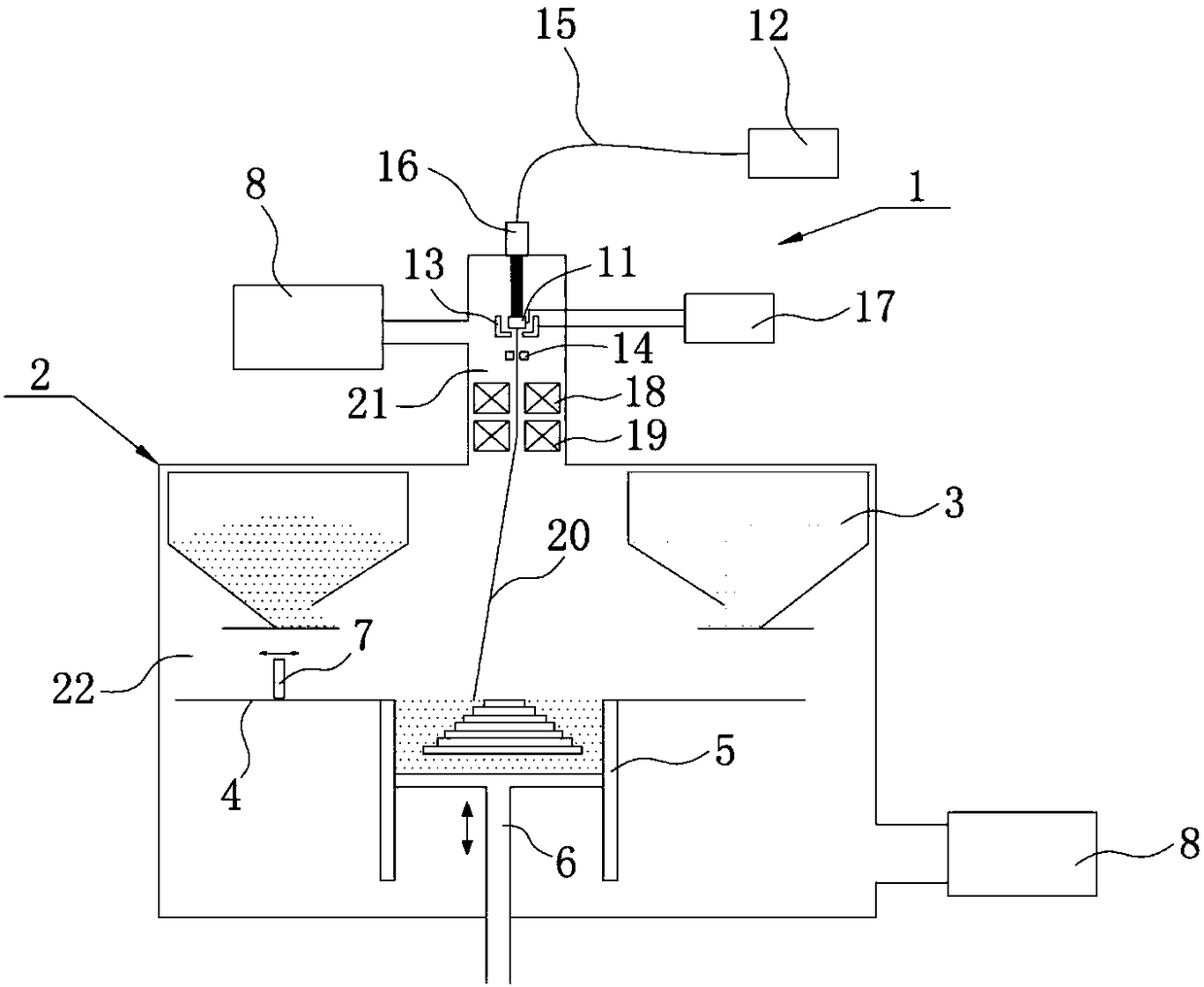

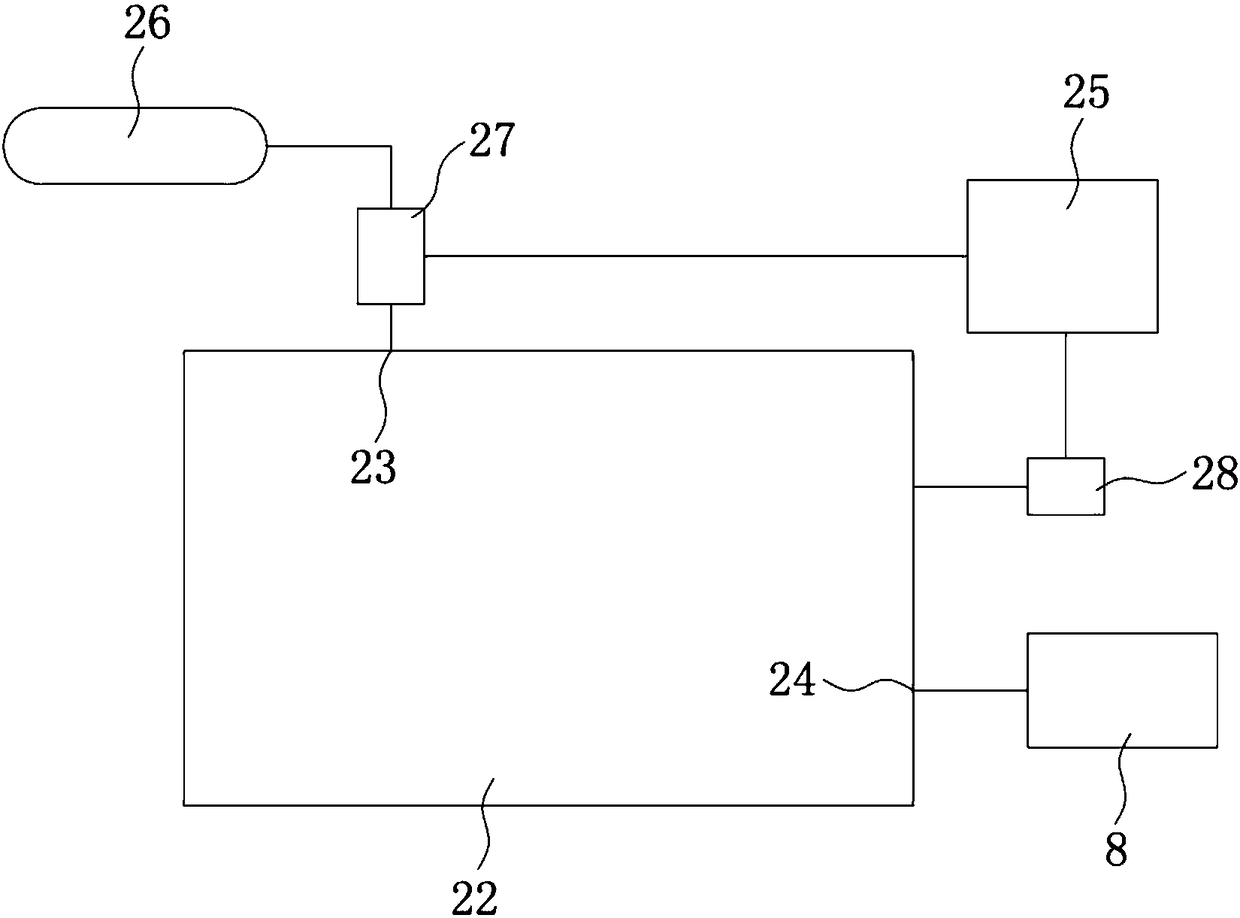

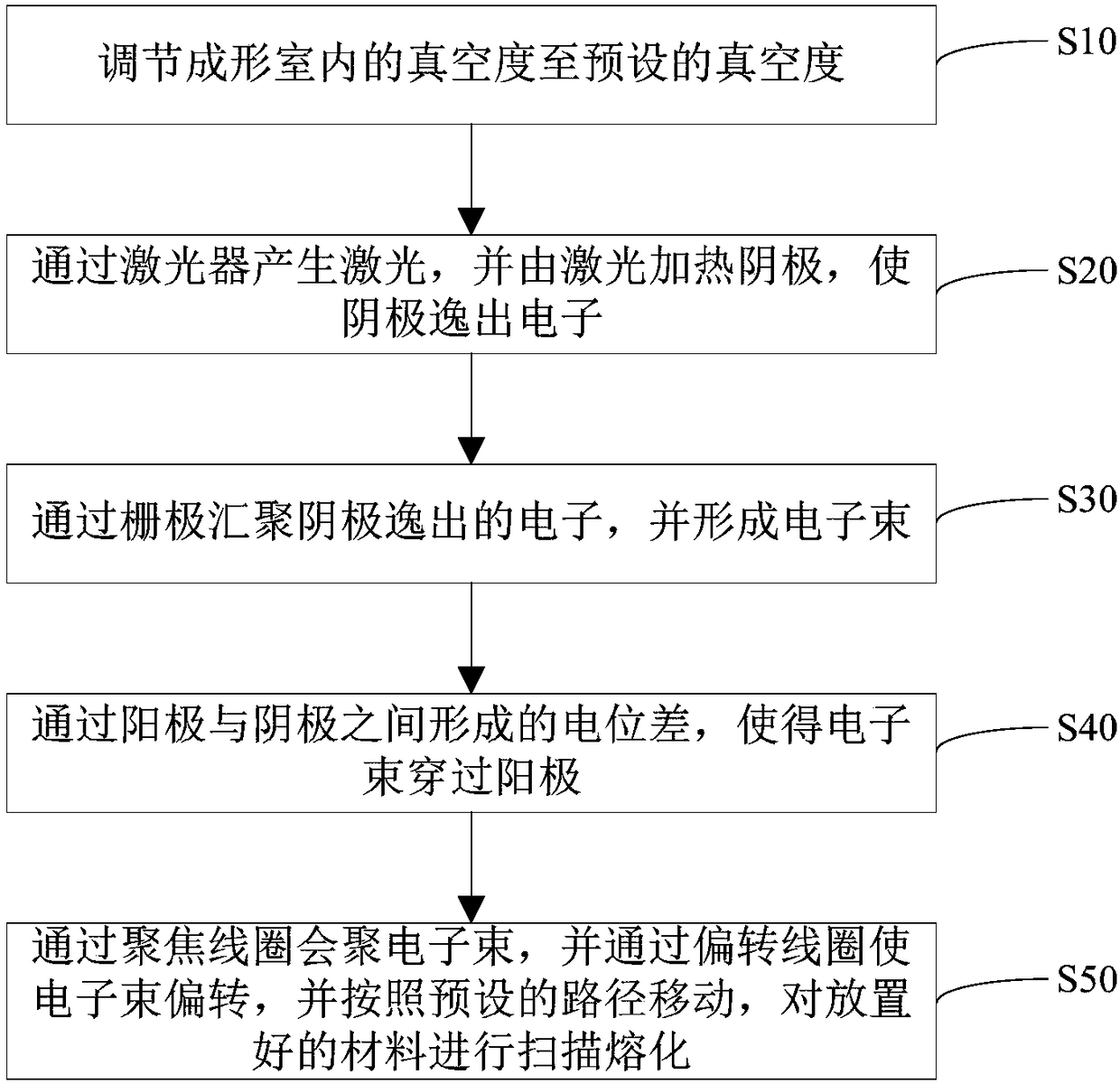

[0042] This embodiment provides an additive manufacturing device, such as figure 1 As shown, the additive manufacturing device includes a ray generating device 1, a forming chamber 2, a hopper 3, a powder spreading platform 4, a forming cylinder 5, a piston 6 and a scraper 7, wherein:

[0043] The above-mentioned ray generating device 1 is arranged on the top of the forming chamber 2, and at least one of the above-mentioned hoppers 3 is arranged in the forming chamber 2. In this embodiment, two hoppers 3 are arranged symmetrically on the left and right sides of the forming chamber 2. , the powder material is housed in the hopper 3 . The above-mentioned powder spreading platform 4 is provided below the hopper 3 , and the powder material in the hopper 3 can be transported onto the powder spreading platform 4 . A forming cylinder 5 is arranged on the powder spreading platform 4, and a piston 6 which can move up and down is arranged in the forming cylinder 5. A movable scraper 7...

Embodiment 2

[0080] The difference between the additive manufacturing device of this embodiment and the first embodiment is that the additive manufacturing device of this embodiment is a wire-feeding type, rather than the powder-spreading structure described in the first embodiment.

[0081] In this example, refer to Figure 5 , the additive manufacturing device includes a ray generating device 1 and a fuse tray 9, on which a fuse 10 is arranged, and the electron beam 20 formed by the above-mentioned ray generating device 1 will be on the formed part of the three-dimensional part To form a molten pool, specifically, the formed part of a three-dimensional part is placed on a mobile platform with at least three degrees of freedom of movement, X, Y, and Z. A molten pool is formed on it.

[0082] Afterwards, the fuse 10 is transported through the fuse tray 9, so that the fuse 10 is filled into the molten pool, and is heated and melted by the electron beam 20 to accumulate, and the three-dimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com