Preparation method of zinc-series metal treatment fluid

A metal treatment, zinc-based technology, applied in the direction of metal material coating technology, etc., can solve the problems of environmental treatment burden of phosphate, short service life of phosphating solution, and high phosphating temperature, and achieve faster phosphating speed and corrosion inhibitor. The effect of thickness and nucleation density on corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

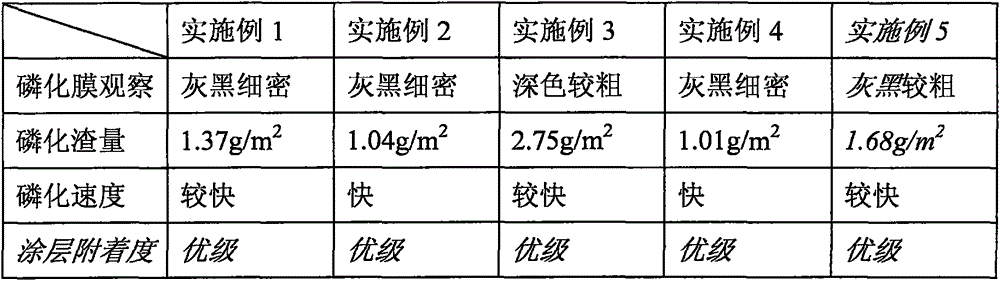

Embodiment 1

[0039] The raw materials of the phosphating solution are composed in parts by weight: 100 parts of zinc dihydrogen phosphate, 25 parts of zinc oxide, 30 parts of phosphoric acid nitric acid mixed solution, 15 parts of calcium nitrate, 2 parts of manganese carbonate, 2 parts of sodium fluorosilicate, sulfuric acid 4 parts of hydroxylamine, 4 parts of triazole compound, 2 parts of sodium citrate, 10 parts of polyphosphate, 2 parts of sodium fluoride, 2 parts of ammonium peroxodisulfate, 5 parts of sodium molybdate, 1 part of hexamethylenetetramine , 3 parts of sodium cyclic trimetaphosphate, 2 parts of nickel sulfate.

[0040] The preparation method is as follows: first dissolve 25 parts of zinc oxide in an acid-resistant container or a phosphating tank with an appropriate amount of water, stir thoroughly, then add 30 parts of phosphoric acid nitric acid mixture and continue stirring, heat to 100-120°C for 2 hours to fully dissolve reaction, after fully reacting, add 100 parts o...

Embodiment 2

[0042] The raw materials of the phosphating solution are composed in parts by weight: 100 parts of zinc dihydrogen phosphate, 25 parts of zinc oxide, 40 parts of phosphoric acid nitric acid mixed solution, 20 parts of calcium nitrate, 2 parts of manganese carbonate, 3.5 parts of sodium fluorosilicate, sulfuric acid 4 parts of hydroxylamine, 4 parts of triazole compound, 2 parts of sodium citrate, 10 parts of polyphosphate, 3 parts of sodium fluoride, 2 parts of ammonium peroxodisulfate, 5 parts of sodium molybdate, 1 part of hexamethylenetetramine , 3 parts of sodium cyclic trimetaphosphate, and 2 parts of nickel sulfate. It can be seen that compared with Example 1, the configuration of the activator component has been increased.

[0043] The preparation method is as follows: first dissolve 25 parts of zinc oxide in an acid-resistant container or a phosphating tank with an appropriate amount of water, stir thoroughly, then add 40 parts of phosphoric acid nitric acid mixture and...

Embodiment 3

[0045] The raw materials of the phosphating solution are composed in parts by weight: 100 parts of zinc dihydrogen phosphate, 25 parts of zinc oxide, 40 parts of phosphoric acid nitric acid mixed solution, 20 parts of calcium nitrate, 2 parts of manganese carbonate, 2 parts of sodium fluorosilicate, sulfuric acid 4 parts of hydroxylamine, 6 parts of triazole compound, 2 parts of sodium citrate, 10 parts of polyphosphate, 2 parts of sodium fluoride, 2 parts of ammonium peroxodisulfate, 8 parts of sodium molybdate, 1 part of hexamethylenetetramine , 3 parts of sodium cyclic trimetaphosphate, and 2 parts of nickel sulfate. It can be seen that compared with Example 1, the configuration of the oxidant component has been increased.

[0046] Its preparation method is as follows: first dissolve 15 parts of zinc oxide in an acid-resistant container or phosphating tank with an appropriate amount of water, stir thoroughly, then add 40 parts of phosphoric acid and continue stirring, heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com