Preparation method of solid hydroxylamine sulfate

A hydroxylamine sulfate and solid technology, applied in the field of preparation of solid hydroxylamine sulfate, can solve the problems of non-compliance with safety production and environmental protection requirements, complex process route, long process flow, etc., and achieves low production cost, short process flow, and improved adsorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

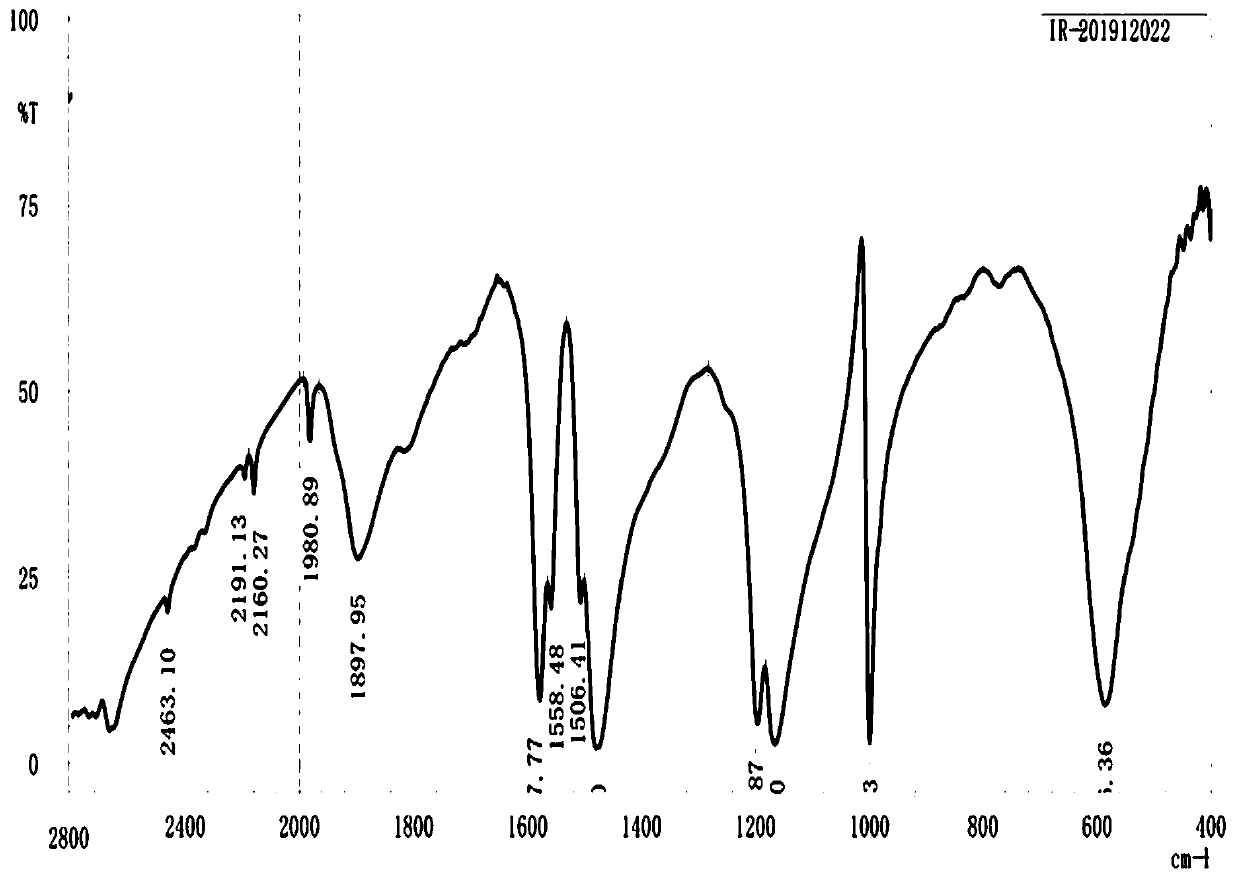

Image

Examples

Embodiment 1

[0023] A preparation method of solid hydroxylamine sulfate, its operation steps are:

[0024] Add 20Kg of concentrated sulfuric acid into the mixing kettle, then add pure water to dilute the sulfuric acid concentration to 20%, stir and mix evenly, add 38Kg of butanone oxime into the mixing kettle, after stirring and mixing, add the feed liquid into the reactor, the reactor Use forced circulation heating, temperature control at 70°C, and reaction time of 5 hours to generate hydroxylamine sulfate and butanone; after the reaction is completed, control the vacuum degree to 0.06MPa, distill the butanone under reduced pressure, and then put the remaining reaction liquid into the separator for stratification. Coarsely separate the organic and inorganic phases, put the obtained lower inorganic phase (hydroxylamine sulfate solution) into the organic matter removal tower, remove the remaining organic matter, and then heat and concentrate the obtained hydroxylamine sulfate mother liquor t...

Embodiment 2

[0032] A preparation method of solid hydroxylamine sulfate, its operation steps are:

[0033] Add 30Kg of concentrated sulfuric acid into the mixing tank, then add pure water to dilute the concentration of sulfuric acid to 30%, stir and mix evenly, add 80Kg of butanone oxime into the mixing tank, after stirring and mixing, add the feed liquid into the reactor, the reactor Use forced circulation heating, temperature control at 85°C, and reaction time of 8 hours to generate hydroxylamine sulfate and butanone; after completing the reaction, control the vacuum degree to 0.08MPa, distill the butanone under reduced pressure, and then put the remaining reaction liquid into the separator for stratification. Coarsely divide the organic and inorganic phases, and enter the obtained lower inorganic phase (hydroxylamine sulfate solution) into the organic matter removal tower to remove the remaining organic matter, and then heat and concentrate the obtained hydroxylamine sulfate mother liquo...

Embodiment 3

[0041] A preparation method of solid hydroxylamine sulfate, its operation steps are:

[0042] Add 40Kg of concentrated sulfuric acid into the mixing kettle, then add pure water to dilute the sulfuric acid concentration to 40%, stir and mix evenly, add 150Kg of butanone oxime into the mixing kettle, after stirring and mixing, add the feed liquid into the reactor, the reactor Use forced circulation heating, temperature control at 95°C, and reaction time of 10 hours to generate hydroxylamine sulfate and butanone; after the reaction is completed, control the vacuum degree to 0.1MPa, distill the butanone under reduced pressure, and then put the remaining reaction liquid into the separator for stratification. Coarsely divide the organic and inorganic phases, and enter the obtained lower inorganic phase (hydroxylamine sulfate solution) into the organic matter removal tower to remove the remaining organic matter, and then heat and concentrate the obtained hydroxylamine sulfate mother l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com