Desliming method for high-argillization high-talc ore

A talc mine, high mud technology, applied in the direction of solid separation, flotation, etc., can solve the problem of non-preliminary desliming, and achieve the effect of improving efficiency and simplifying the flotation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

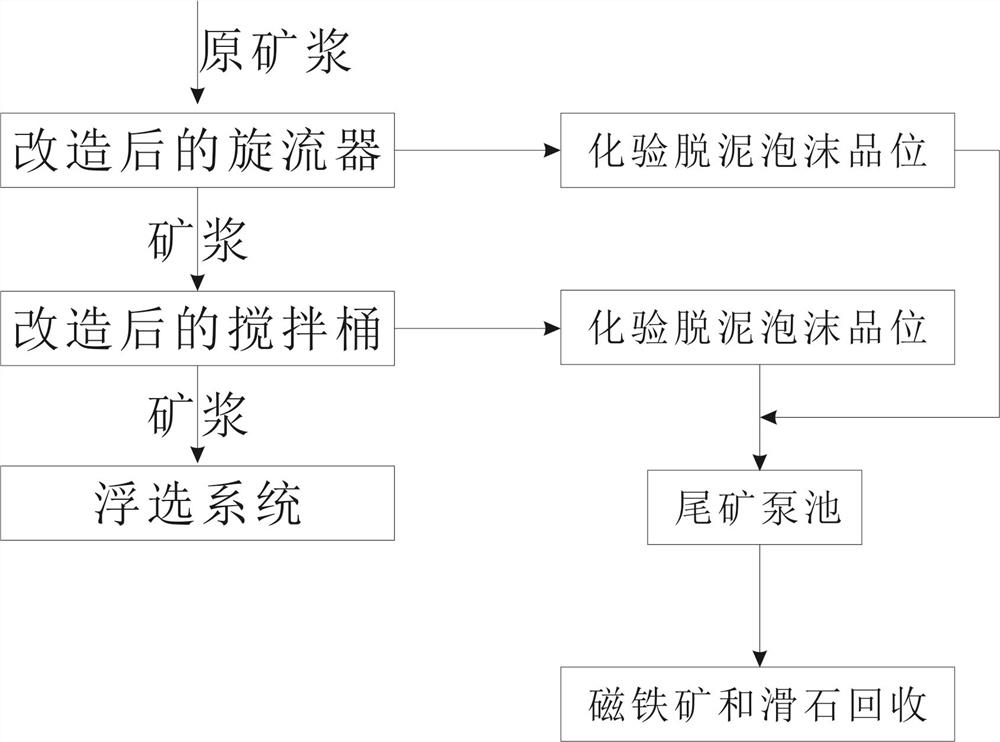

[0029] A kind of desliming method of high-mud high-talc ore described in conjunction with accompanying drawing, comprises the following steps

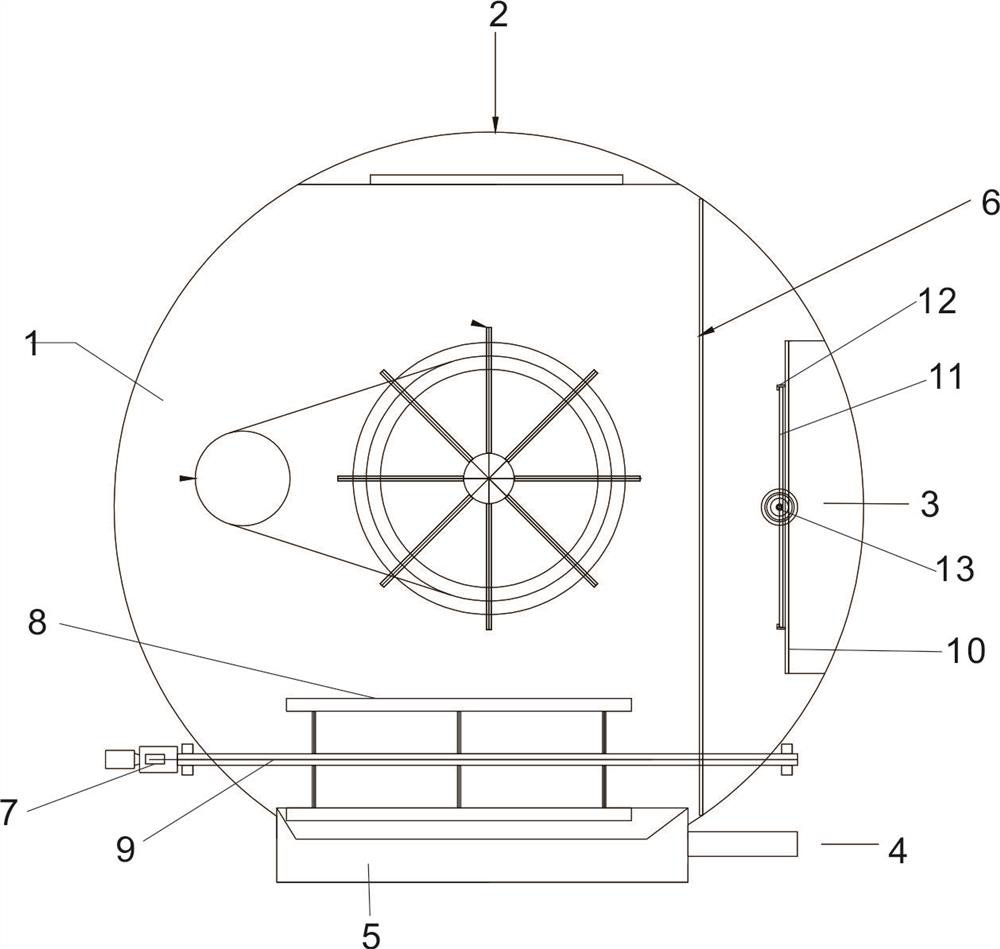

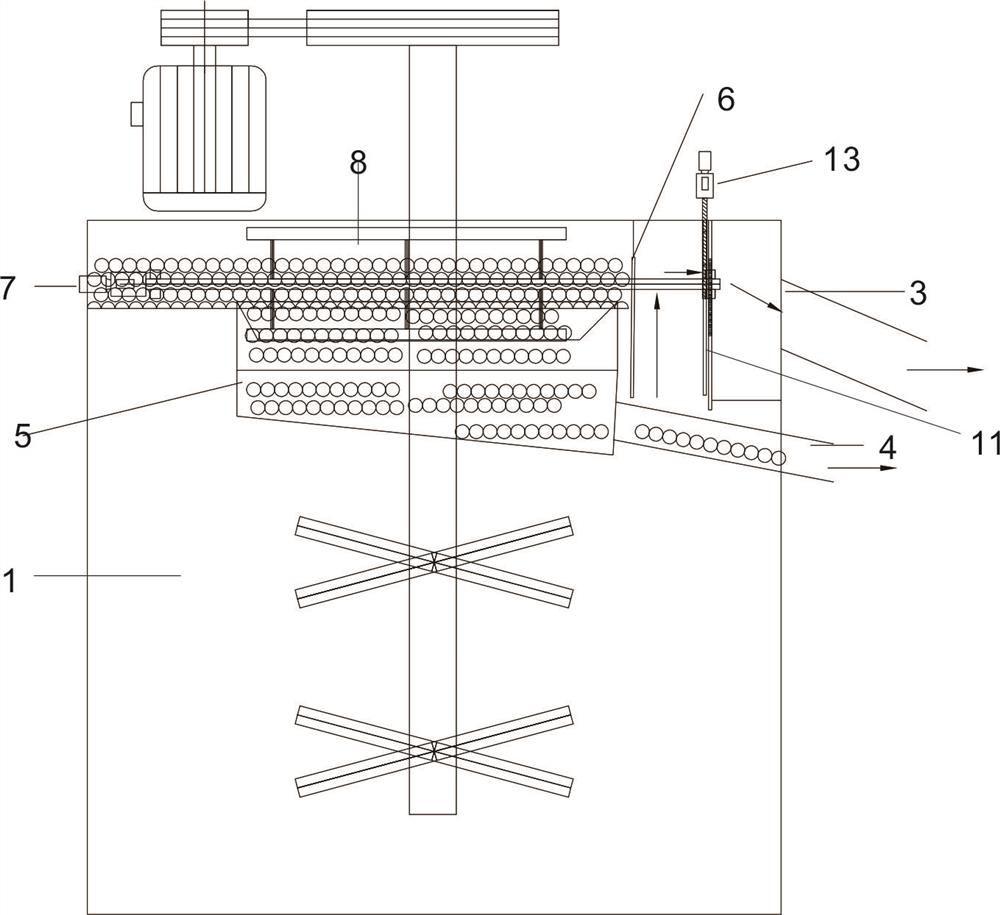

[0030] 1. Retrofit the cyclone

[0031] The position of the overflow pipe of the cyclone is adjusted to ensure that the bubble blocking plate 6, the foam scraping device, the foam tank 5 and the gate lifting mechanism can be installed on the cyclone, and the bubble blocking plate 6 will make the inner cavity of the cyclone The upper side is separated, one side of the foam blocking plate 6 is provided with a pulp outlet, and the other side is provided with a foam scraping device, and the pulp of the cyclone is gathered on this side, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com