Collophanite flotation collector and application thereof

A technology of collophosphate rock and collector, applied in flotation, solid separation and other directions, can solve the problems of high energy consumption, unfavorable environmental protection, etc., and achieve the effect of saving heating costs, less coal burning, and simplifying the flotation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

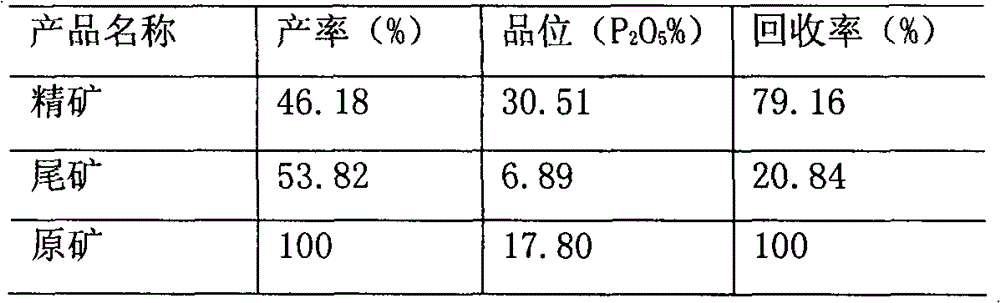

[0034] Taking the three-layer ore (medium and low-grade phosphate rock) of Hubei Dayukou phosphate rock as raw material, the combination agent provided by the present invention is used as collector to investigate the flotation effect

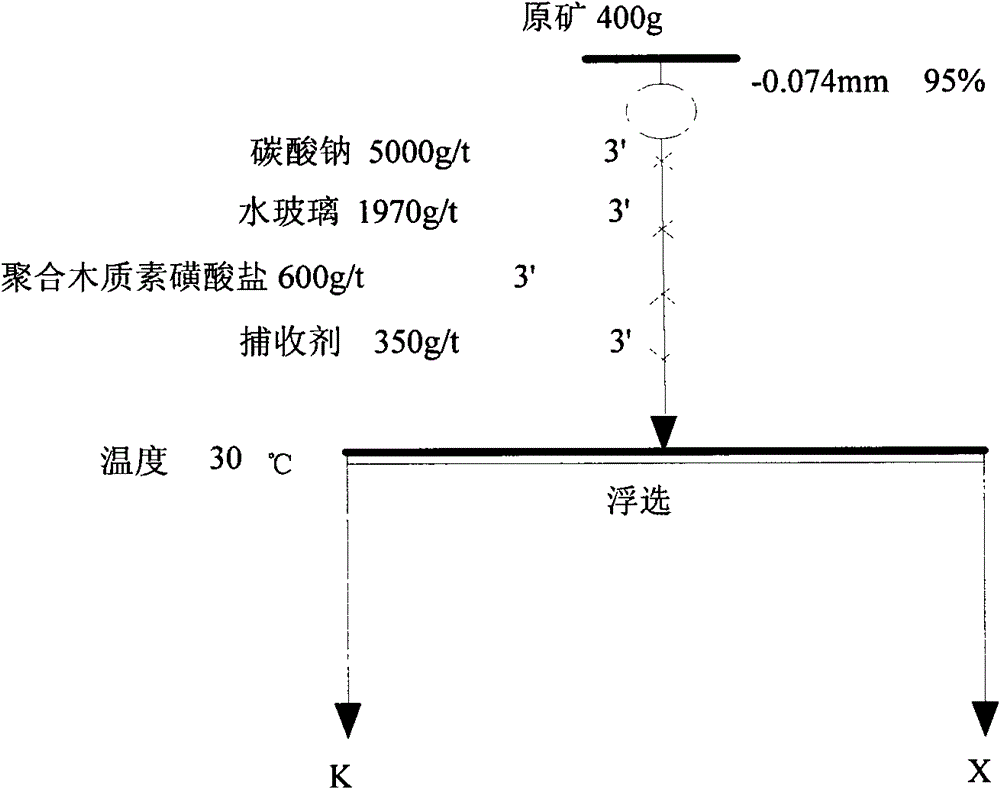

[0035] Flotation process and reagent addition see figure 1 .

[0036] Add 400g of raw ore into the grinding machine each time, and grind to -0.074mm to be 95%. The test is carried out on a 1L hanging tank flotation machine. Adjust the flotation temperature and follow the dosing sequence and dosage shown in the test process. Dosing, every time the dosing is completed, stir for 3 minutes, and finally inflate for flotation. Separately filter the foam (i.e. concentrate) and the product in the tank (i.e. tailings), dry, weigh and send to the laboratory. (The following collectors 350g / t are based on the mass of the collector itself)

[0037] Inhibitor: polymeric lignosulfonate

[0038] Collector composition (mass ratio): mixed hydroxamic acid: C 18...

Embodiment 2

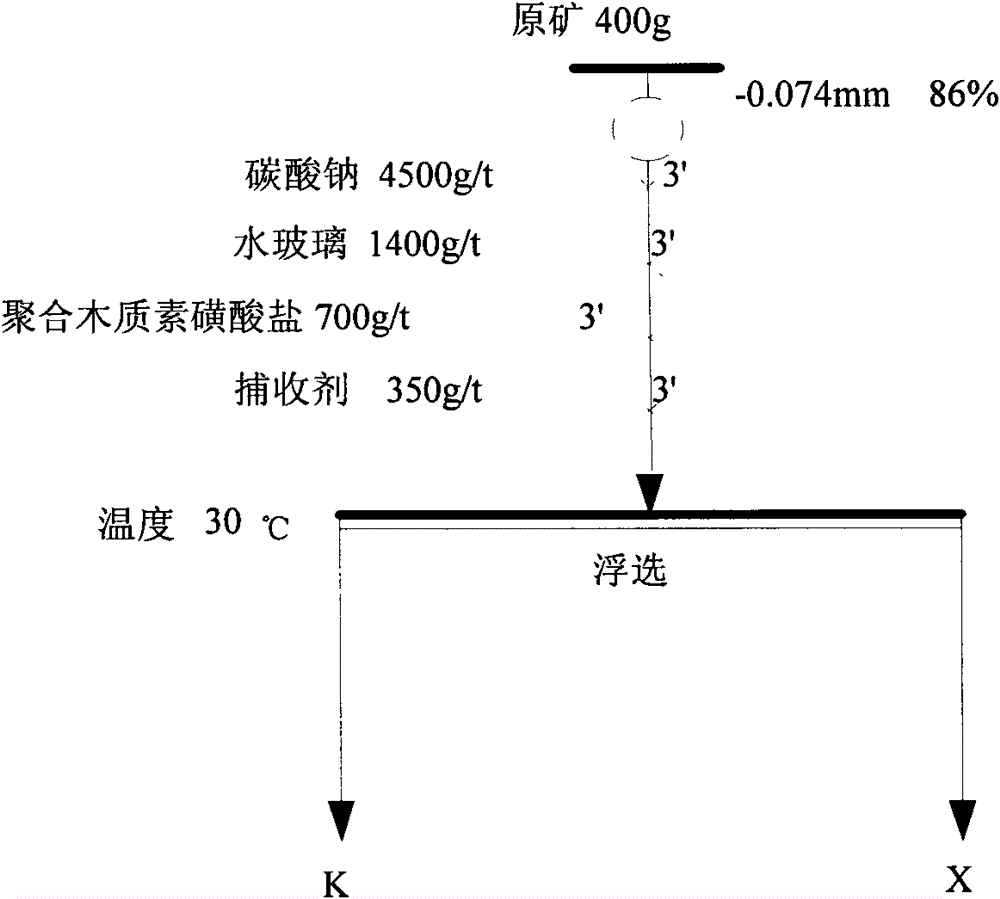

[0044] Taking the three-layer ore (medium and low-grade phosphate rock) of Hubei Dayukou phosphate rock as raw material, the combination agent provided by the present invention is used as collector to investigate the flotation effect

[0045] Flotation process see figure 2 . Add 400g of raw ore into the grinding machine each time, and grind to -0.074mm to be 95%. The test is carried out on a 1L hanging tank flotation machine. Adjust the flotation temperature and follow the dosing sequence and dosage shown in the test process. Dosing, every time the dosing is completed, stir for 3 minutes, and finally inflate for flotation. Separately filter the foam (i.e. concentrate) and the product in the tank (i.e. tailings), dry, weigh and send to the laboratory. (The following collectors 350g / t are based on the mass of the collector itself)

[0046] Inhibitor: polymerized lignosulfonate (molecular weight 2000-100000)

[0047] Collector composition (mass ratio): mixed hydroxamic acid:...

Embodiment 3

[0053] Taking the three-layer ore (medium and low-grade phosphate rock) of Hubei Dayukou phosphate rock as raw material, the combination agent provided by the present invention is used as collector to investigate the flotation effect

[0054] Flotation process see figure 1 . Add 400g of raw ore into the grinding machine each time, and grind to -0.074mm to be 95%. The test is carried out on a 1L hanging tank flotation machine. Adjust the flotation temperature and follow the dosing sequence and dosage shown in the test process. Dosing, every time the dosing is completed, stir for 3 minutes, and finally inflate for flotation. Separately filter the foam (i.e. concentrate) and the product in the tank (i.e. tailings), dry, weigh and send to the laboratory. (The following collectors 350g / t are based on the mass of the collector itself)

[0055] Inhibitor: polymeric lignosulfonate

[0056] Collector composition (mass ratio): mixed hydroxamic acid: C 18 Unsaturated fatty acid: OP-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com