Method for sorting low-grade titaniferous magnetite

A titanium-magnetite, low-grade technology, applied in the field of comprehensive recovery of magnetite and ilmenite, can solve the problem of single configuration mode of weak magnetic separation and strong magnetic separation, low separation efficiency of ilmenite collector, It is not suitable for the comprehensive recovery of iron and ilmenite, so as to improve the flotation effect, reduce the amount of follow-up operations, and reduce the amount of floating ore

Active Publication Date: 2018-02-02

SINOSTEEL MAANSHAN INST OF MINING RES

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] (2) The configuration mode of weak magnetic separation and strong magnetic separation is single

[0007] (3) The separation efficiency of conventional ilmenite collectors is not high

However, this ore dressing process has problems such

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Login to View More

Abstract

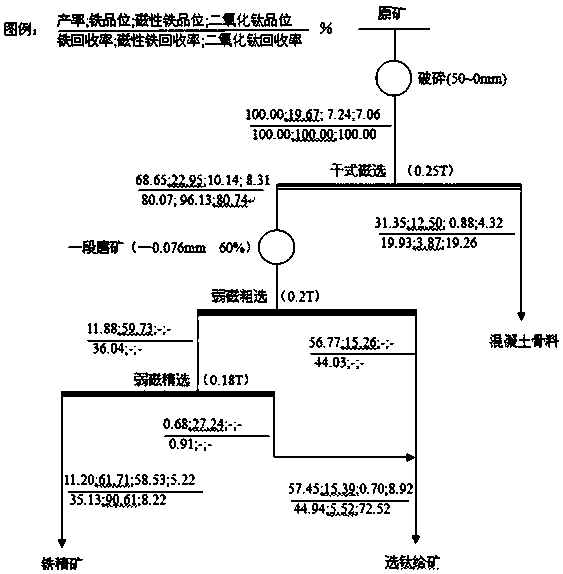

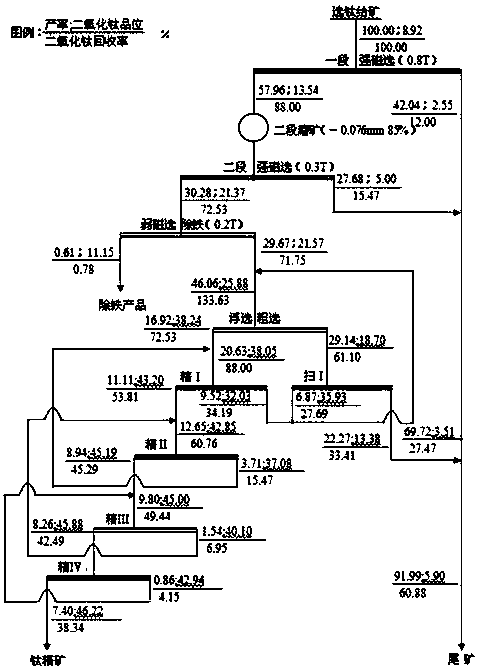

The invention discloses a method for sorting low-grade titaniferous magnetite. The method includes the steps that an intermediately-crushed material is fed into dry-type magnetic separation operation,and dry-type magnetic separation tailings are discharged; dry-type magnetic concentrate is subjected to primary ore grinding, weak magnetic roughing and weak magnetic selection, and magnetite concentrate with the iron ore concentrate grade being larger than or equal to 60% is obtained; weak magnetic roughing and weak magnetic selection tailings are combined into ilmenite beneficiation ore; the ilmenite beneficiation ore is subjected to primary strong magnetic separation at first, obtained primary strong magnetic concentrate is fed into secondary ore grinding, secondary strong magnetic separation and weak magnetic separation deironing operations, secondary strong magnetic separation tailings are thrown out, and weak magnetic separation deironing products are discharged; and weak magnetic separation deironed tailings serve as titanium flotation ore, the one-roughing, four-selection and one-scavenging direct flotation process that middlings can return in sequence is adopted in titanium flotation, flotation scavenging tailings are thrown out, and titanium concentrate with the TiO2 grade being larger than or equal to 46% is obtained. The method for sorting the low-grade titaniferous magnetite has the advantages of being good in energy-saving effect, large in handling capacity, high in adaptability, high in comprehensive utilization rate, good in economic benefit and the like, and can be applied and popularized to similar mines.

Description

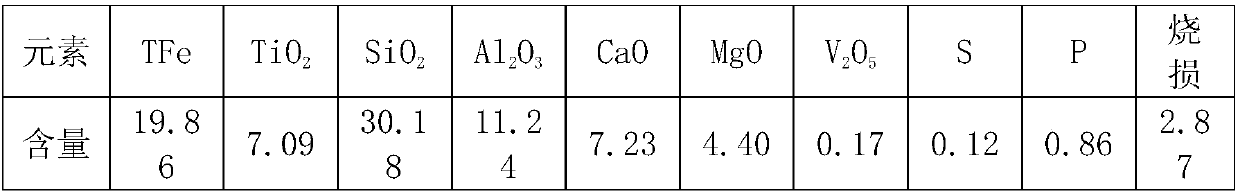

technical field [0001] The invention relates to a separation, enrichment and beneficiation method of titanium and iron ore, which is especially suitable for the comprehensive recovery of magnetite and ilmenite from low-grade titanium-containing magnetite. Background technique [0002] my country's titanium resources are quite rich, accounting for about 48% of the world's total reserves, of which ilmenite reserves account for as high as 98% of my country's titanium resources. Although my country's ilmenite resources are very rich, most of them are low-grade primary ores, and most of them are embedded with finer particles, which are often associated with magnetite. The ore properties are complex and belong to refractory ores. With the development of economy and society, the demand for titanium resources in various infrastructures in my country is increasing, and the shortage of high-quality titanium resources has become an indisputable fact. In order to meet the needs of the d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C21/00B03C1/02B03C1/10B03C1/025B03D1/00B03D1/018B03D101/02B03D101/06B03D103/02

CPCB02C21/00B03C1/02B03C1/025B03C1/10B03D1/00B03D1/018B03D2201/02B03D2201/06B03D2203/02

Inventor 陈洲杨任新袁启东刘军王炬李亮张永许鹏云李俊宁骆洪振

Owner SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com