High-iron red mud strong-magnetic preseparation-suspension-state direct reduction-high-temperature melting separation method

A high-speed iron red mud, strong magnetic technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of occupying land, wasting resources, environmental pollution and safety hazards, saving energy, improving product quality, The effect of large reaction contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

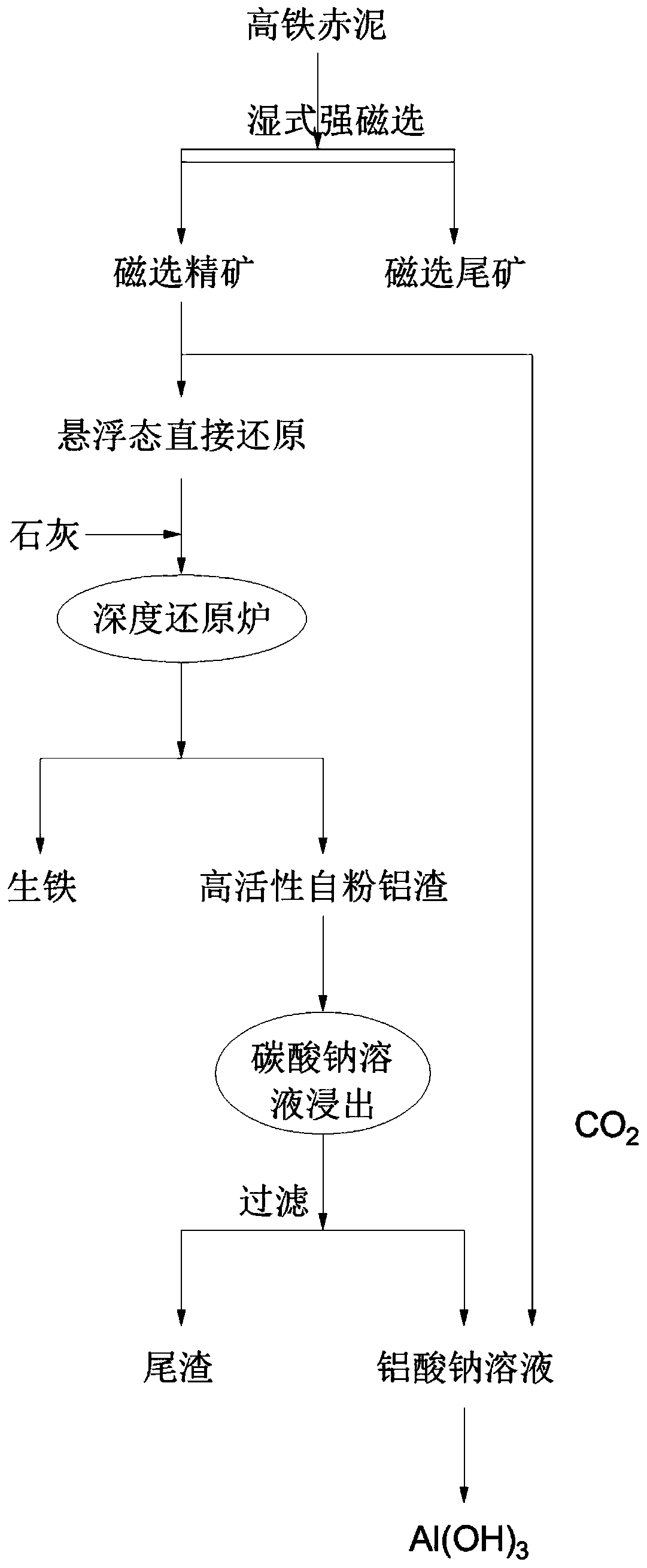

[0029] In this embodiment, a certain high-iron red mud containing TFe 32.04% by weight percentage, Al 2 o 3 15.78%, SiO 2 9.47%, high-iron red mud strong magnetic pre-selection-suspension state direct reduction-high temperature melting method such as figure 1 shown, follow the steps below:

[0030] (1) Firstly, a section of wet strong magnetic separation is used for magnetic separation of red mud, and the magnetic field strength of magnetic separation is 636.62kA / m to obtain magnetic separation concentrate and magnetic separation tailings; the iron grade of magnetic separation concentrate is 44.68%, SiO 2 The quality score is 4.60%;

[0031] (2) The magnetic separation concentrate is directly reduced in a suspension state at a temperature of 900° C. for 60 minutes, and part of the iron oxides are reduced to metallic iron; the metallization rate of iron after the magnetic separation concentrate is reduced and roasted is 90.91%;

[0032] (3) Add lime and mix the high-temper...

Embodiment 2

[0036] In this embodiment, a certain high-iron red mud containing TFe 35.40% by weight percentage, Al 2 o 3 18.85%, SiO 2 7.09%. Method is the same as embodiment 1 and figure 1 , the difference is:

[0037] (1) The magnetic field strength of wet magnetic separation is 716.19kA / m; the iron grade of magnetic separation concentrate is 46.64%, SiO 2 The content is 3.09%;

[0038] (2) The suspension state direct reduction temperature is 1000°C, and the time is 50 minutes; the metallization rate of iron after the pre-selected concentrate is reduced and roasted is 91.05%;

[0039] (3) The reduction temperature of the deep reduction furnace is 1300°C; the reduction time of molten iron is 40 minutes, and the amount of lime added is n(CaO) / n(Al 2 o 3 )=1.85, the amount percentage contains Fe 92.03%, C 3.68%, P 0.03%, S 0.02%, Si0.43%;

[0040] (4) The concentration of sodium carbonate solution used for leaching is 85g / L, the leaching temperature is 75°C, the leaching time is 95 ...

Embodiment 3

[0043] In this embodiment, a certain high-iron red mud containing TFe 30.80% by weight percentage, Al 2 o 3 19.69%, SiO 2 8.68%. Method is with embodiment 1, and difference is:

[0044] (1) The magnetic field strength of wet magnetic separation is 795.77kA / m; the iron grade of magnetic separation concentrate is 42.06%, SiO 2 The mass fraction is 4.59%.

[0045] (2) Suspension state direct reduction temperature is 800 ℃, and time is 40min; the metallization rate of iron after reduction roasting of preselected concentrate is 93.78%;

[0046] (3) The reduction temperature of the deep reduction furnace is 1350°C, the time is 50min, and the amount of lime added is n(CaO) / n(Al 2 o 3 )=1.95,; molten iron contains Fe 93.15%, C 3.88%, P 0.03%, S 0.02%, Si0.35% by mass percentage;

[0047] (4) The concentration of sodium carbonate solution used for leaching is 100g / L, the leaching temperature is 85°C, the leaching time is 105 minutes, the liquid-solid ratio is 9:1; the alumina lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com