A pre-selection process for surrounding rock containing magnetite

A mine enclosure and magnet technology, which is applied in the field of pre-selection of low-grade magnetite-containing surrounding rocks, can solve the problems of low yield of tailings building materials and high crushing energy consumption, so as to reduce emissions, improve selection grade, and reduce disposal volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

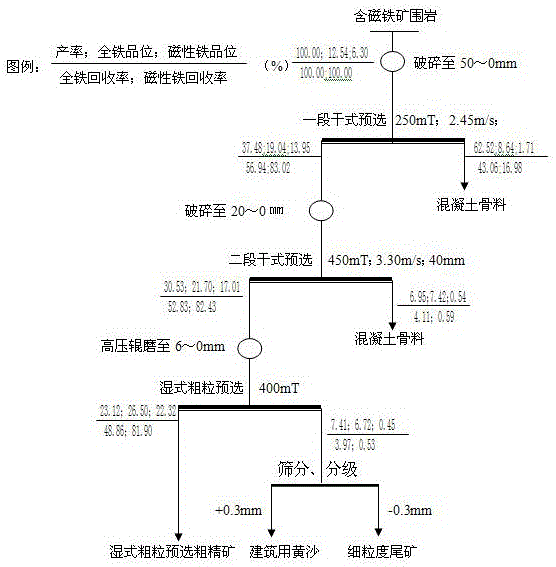

[0026] In order to describe the present invention, a pre-selection process of magnetite-containing surrounding rock of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0027] The object of treatment in this embodiment is the magnetite-containing surrounding rock stockpiled in the dump site of the Nanshan mining area of Masteel Group. The multi-element analysis and iron phase analysis of the magnetite-containing surrounding rock were carried out, and the results are shown in Table 1 and Table 2.

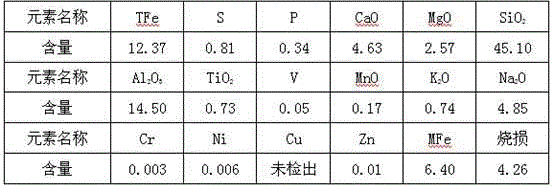

[0028] Table 1 Chemical multi-element analysis results of magnetite-bearing surrounding rocks (%)

[0029]

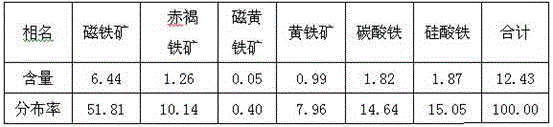

[0030] Table 2 Analytical results of iron phases in surrounding rocks containing magnetite (%)

[0031]

[0032] The analysis shows that the iron content of the surrounding rock containing magnetite is very low, with a total iron grade of 12.37% and a magnetic iron grade of 6.40%; impurities S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com