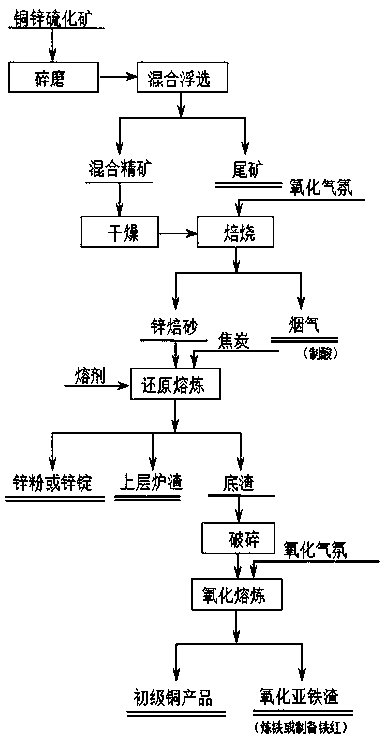

Dressing and smelting combination method for copper-zinc sulfide ores difficult to treat

A technology for combining beneficiation and smelting and sulfide ore, applied in the field of beneficiation and smelting, can solve the problems of difficult separation of copper-zinc sulfide ore, difficulty in industrialization implementation, large discharge of three wastes, etc., achieves good prospects for industrial promotion and application, and simplifies the flotation process. , Improve the effect of recycling indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of dressing and smelting combined method of refractory copper-zinc sulfide ore, concrete operation is as follows:

[0029] A refractory copper-zinc sulfide ore ore, the mass percentage of its chemical composition is: Cu 0.5%, Zn 4%, S 6%, Fe 10.5%, the content of valuable element Au is 0.5 g / t, the ore is crushed 1. After ore grinding treatment, 65% of the material with a particle size of less than 74 μm in mass is obtained, and then copper-zinc mixed concentrate is obtained through copper-zinc mixed flotation, and its chemical composition is mainly: Cu 5.5%, Zn24.6%, S 31.5 %, Fe 21.5%, SiO 2 6.85%, the content of the valuable element Au is 4.5g / t, the mixed concentrate is stacked in the silo, and the concentrate with a water content of 10% is obtained after natural air drying.

[0030] Roast the concentrate with a water content of 10% at 850°C for 3 hours to obtain zinc calcine with a sulfur content of 0.8% and a water content of 0.45%. Mix coke...

Embodiment 2

[0033] Embodiment 2: a kind of dressing and smelting combined method of refractory copper-zinc sulfide ore, concrete operation is as follows:

[0034] A refractory copper-zinc sulfide ore, the mass percentage of its chemical composition is: Cu: 0.7%, Zn: 5.5%, S: 8.2%, Pb: 0.25%, Fe: 14%, the content of valuable element Au is 0.7% g / t, after the ore is crushed and ground, the material with a particle size of less than 74μm in terms of mass is obtained, accounting for 60% of the material, and then copper-zinc mixed concentrate is obtained through copper-zinc mixed flotation, and its chemical composition is mainly: Cu: 7.2%, Zn: 26.7%, Pb: 2.4%, S: 29.8%, Fe: 22.4%, SiO 2 : 8.97%, the content of valuable element Au is 8 g / t, the mixed concentrate is stacked in the silo, heated and dried at 80°C to obtain a concentrate with a water content of 7.5%.

[0035] Roast the concentrate with a water content of 7.5% at a temperature of 1000°C for 1 hour to obtain a zinc calcine with a su...

Embodiment 3

[0038] Embodiment 3: a kind of dressing and smelting combined method of refractory copper-zinc sulfide ore, concrete operation is as follows:

[0039] A refractory copper-zinc sulfide ore, the mass percentage of its chemical composition is: Cu 1.5%, Zn 7%, Sn 0.2% S9.5%, Fe 18%, the content of valuable element Au is 1.5 g / t, will After the ore is crushed and ground, 75% of the material is obtained with a particle size of less than 74μm in terms of mass, and then copper-zinc mixed concentrate is obtained through copper-zinc mixed flotation, and its chemical composition is mainly: Cu 12.6%, Zn 26.5% , Sn 1.8%, S 33%, Fe 21.5%, SiO 2 3.24%, the content of the valuable element Au is 8g / t, the mixed concentrate is stacked in the silo, heated and dried at 150°C to obtain a concentrate with a water content of 5%.

[0040] Roast the concentrate with a water content of 5% at 1050°C for 3 hours to obtain a zinc calcine with a sulfur content of 1% and a water content of 0.1%. Mix coke,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com