Kitchen garbage component sorting machine

A kitchen waste and sorting machine technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of harmful workers' health, harsh working environment, low working efficiency, etc., and achieve high working efficiency, The effect of good sorting quality and less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

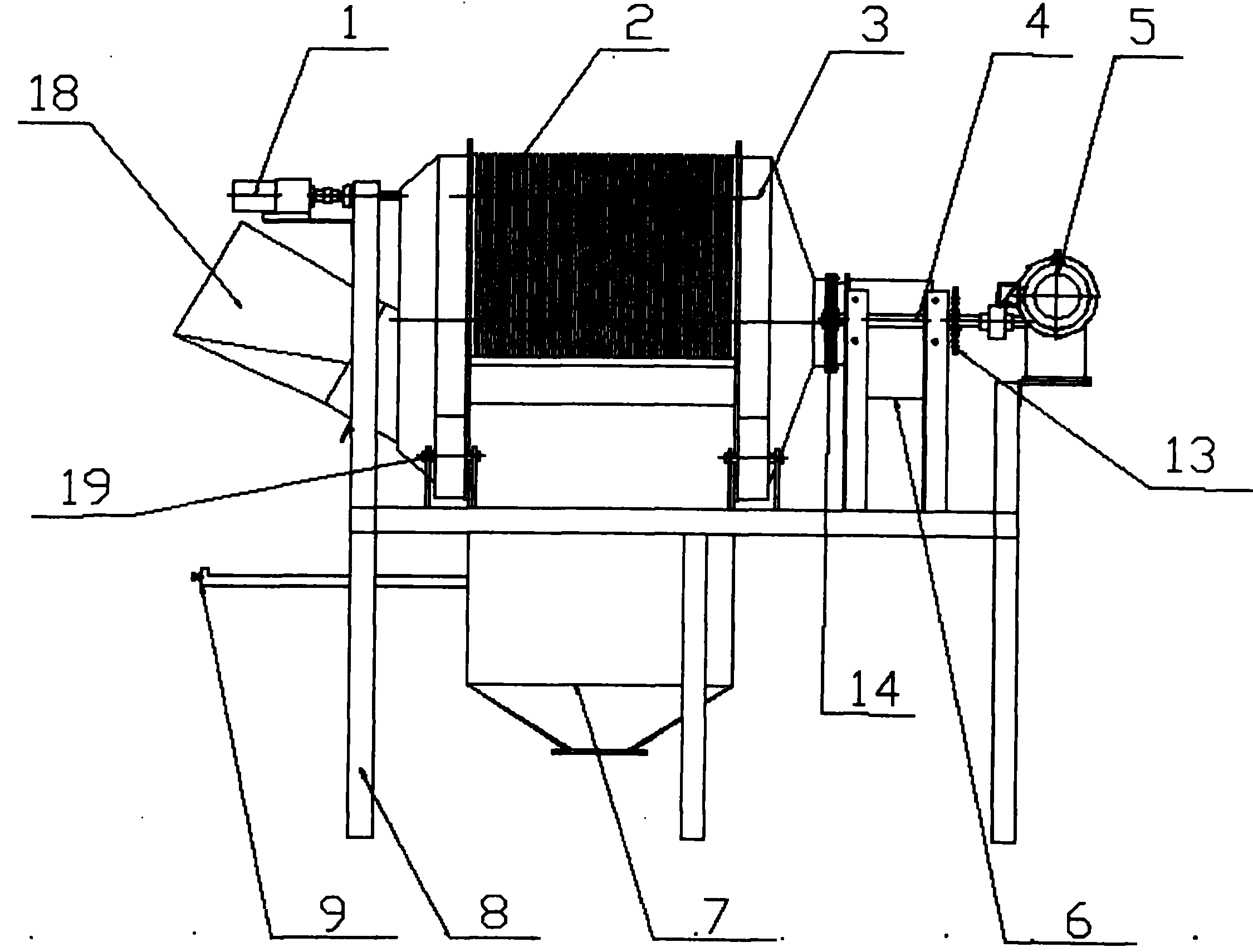

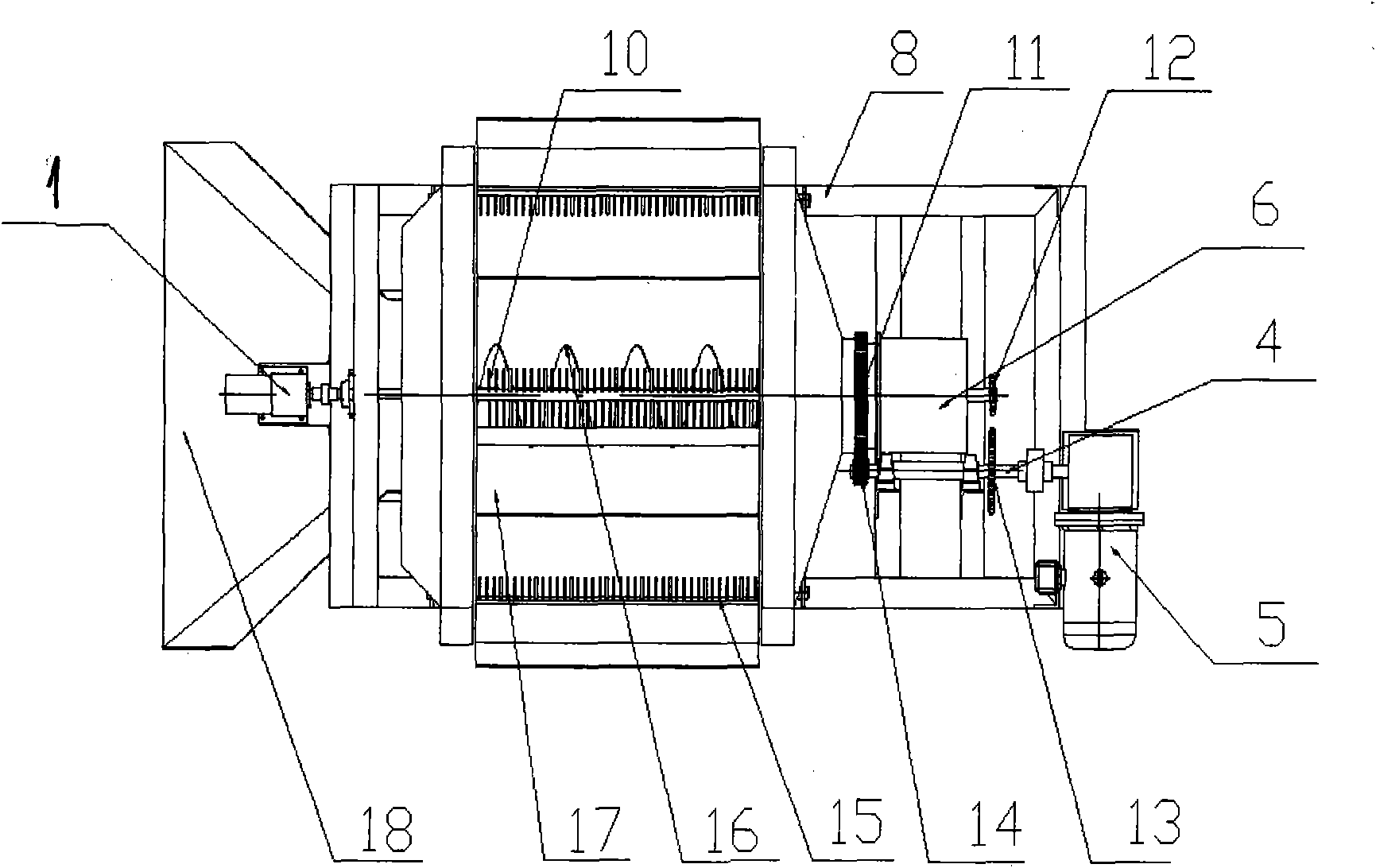

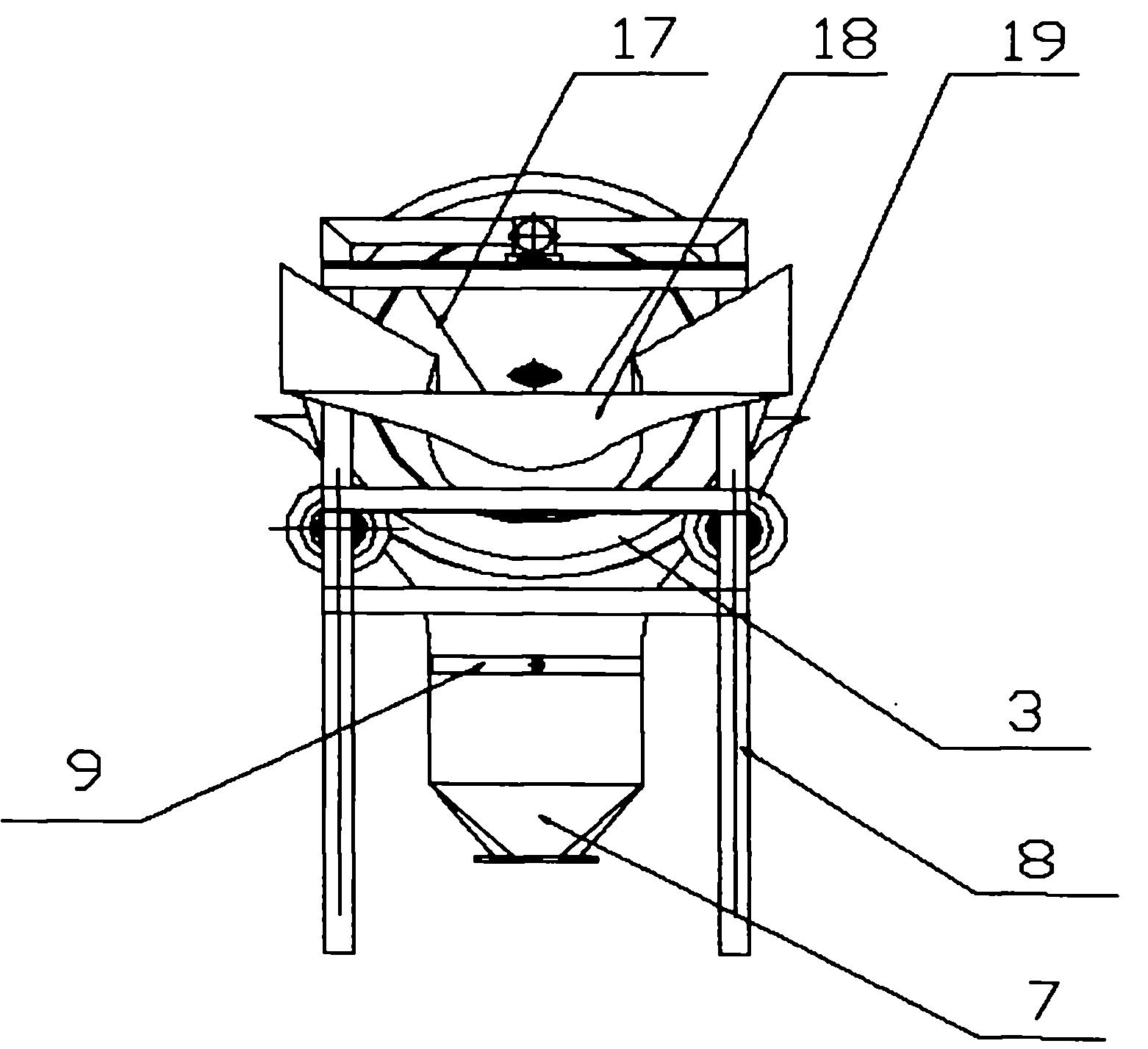

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A sorting machine for kitchen waste components, in which two sets of four support rollers 19 are correspondingly equipped on the upper middle part of the frame assembly 8, and the two drums 3 on the left and right sides are respectively arranged on a set of two support rollers. On the roller 19, the cylindrical grille 2 is fixed between the opposite sides of the two drums 3 on the left and right sides, the ring gear 11 is fixed on the drum 3 on the right side, and the baffle plate 15 is installed on the cylindrical grille 2 Above, the cleaning brush roller 10 and the screw conveyor 16 are assembled on the frame assembly 8, and the cleaning brush roller 10 is located above the screw conveyor 16, and the cylindrical grid 2 will clean the brush roller 10 and the screw conveyor 16 as a whole Containment, the driven sprocket 12 is fixed on the outer end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com